processing and pelletizing of low grade

processing and pelletizing of low grade

PROCESSING AND PELLETIZING OF LOW GRADE MALAYSIAN

PROCESSING AND PELLETIZING OF LOW GRADE MALAYSIAN IRON ORE HATEM M BELHAJ UNIVERSITY SAINS MALAYSIA 2008 View metadata, citation and similar papers at coreacuk brought to you by CORE provided by Repository@USMThis paper briefly outlines the necessity of blending, the relevance of beneficiation and Induration aspects of lowgrade iron ores to make them suitable for Blending, Processing, and Pelletization of LowGrade

Iron Ore Pelletizing Process: An Overview IntechOpen

However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines Upgraded concentrates can be used as charge materials for pelletization This paper discuss about upgradation of lowgrade iron (PDF) Processing of Low Grade Iron Ore Fines and

(PDF) THE GROWING IMPORTANCE OF PELLETIZING FOR

View Show abstract PDF In the last years, pelletizing has been playing an important role in iron ore mining and in iron Recently, the grade of iron ore deposits has deteriorated and further development of low grade deposits is desired Presently, the most effective and often followed route taken to Beneficiation Plants and Pelletizing Plants for Utilizing Low Grade

Iron ore pelletization ScienceDirect

Iron ore pellets are essential burden materials to improve the performance of modern blast furnaces, because they possess high iron grade, low silica and alumina The pelletizing process agglomerates ore fines previously considered as tailings and makes its application possible in the form of pellets During the process, the pellets are subjected toThe 3 basic stages of any Pelletizing Process

A Study of Carbon‐Burdened and Cold‐Bonded Pelletizing

A Study of Carbon‐Burdened and Cold‐Bonded Pelletizing‐Electrosmelting Process Disposing Low‐Grade Manganese Ore 3rd The sinter production from concentrate of lowgrade manganese ore for use in the production of ferrosilicomanganese was discussed It was found that the Processing and production of pellets from poorgrade manganese

Pelletizing Aids in Upgrading LowGrade Nickel

Lowgrade nickel laterite ores will be an important source of the metal in the future as demand increases in the face of declining ore grades As nickel producers continue to implement the reduction roastingmagnetic Biobeneficiation to upgrade lowgrade sulfide and iron ores has the potential to turn closed mines or uneconomic mineral deposits and secondary wastes and materials into economic resources Microorganisms and their metabolites have been commercially applied in the bioleaching of metals from medium and lowgrade sulfide minerals for many yearsIron Ore ScienceDirect

Pelletizing of Iron Ore with High Iron Grade and Low Silicon

Abstract In this paper, an iron ore with high iron grade and low silicon content was used in pelletizing experiments Specific surface areas were tested, and it would increase slowly and thenProcessing And Pelletizing Of Low Grade Malaysian Iron Ore × Close Log In Log in with Facebook Log in with Google or Password Remember me on this computer or reset password Enter the address you signed up with and we'll you a reset link Need an account? Click here to sign up Log In Sign Up Log In; Sign Up; moreProcessing And Pelletizing Of Low Grade Malaysian Iron Ore

Processing And Pelletizing Of Low Grade

The study was carried out in a 4m tonne iron ore pelletizing industry located in Odisha, India from March to December 2015 The pellet plant used travelling grate technology to convert low grade fines into valueadded pellets The slurry was received at the pellet plant from the beneficiation plant through a 220km pipe lineThe concentration of lowgrade iron ores is vital to the continued availability of iron and steel in our everyday lives (Eisele and Kawatra, 2003;Kawatra and Claremboux, 2021a;Zhang et al, 2021)(PDF) THE GROWING IMPORTANCE OF PELLETIZING FOR IRON

Iron Ore Pelletizing Process: An Overview ResearchGate

has deteriorated and lowgrade iron ore has been processed The fines resulting from the enrichment by separation after liberation by size reduction must be agglomerated in a pelletProcessing and pelletizing of low grade malaysian ePrints@USM EN English Deutsch Français Español Português Italiano Român Nederlands Latina Dansk Svenska Norsk Magyar Bahasa Indonesia Türkçe Suomi Latvian Processing and pelletizing of low grade malaysian

PROCESSING AND PELLETIZING OF LOW GRADE MALAYSIAN

Home > Documents > PROCESSING AND PELLETIZING OF LOW GRADE MALAYSIAN PROCESSING AND PELLETIZING OF LOW GRADE MALAYSIAN Date post: 07Jul2018: Category: Documents: Author: trinhnguyet View: 225 times: Download: 1 times: Download Report this document Share thisMay Concentrate Iron ore, as a refractory iron concentrate, deteriorates the permeability of the sintered layer during the sintering process due to its fine particle size and poor granulating performance Therefore, it cannot be widely used in iron ore sintering In this study, the strengthening granulation of May Concentrate Iron ore using pre Metals Free FullText Strengthening Granulating and Sintering

(PDF) Iron ore pelletization ResearchGate

Arrium Australia 0810 0810 0440 440 Iron Ore The pelletizing process involves the preparation of ra w materials; the proportioning and mixing of raw materials; the formation, preheating, andIn the present study, calcination properties of HekimhanDeveci siderite (FeCO3) ore and the effect of calcination process before the pelletization on strength of pellet were investigated and evaluated Two different calcination processes were followed One of them is the traditional calcination process and the other one is microwave Calcination and Pelletizing of Siderite Ore IntechOpen

Strengthening pelletization of manganese ore fines containing

The product pellets contain high Mn grade and low impurities, ZHUANG Jianming, ZUO Wenliang Research on rhodochrosite pelletizing [J] Sintering and Pelletizing, 1996, 21(5): 9–14 (in Chinese) Google Scholar School of Minerals Processing and Bioengineering, Central South University,Traditionally, fine ores are treated either by the process of sintering and/or by pelletizing to prepare an agglomerate with suitable metallurgical characteristics for ironmaking processes The(PDF) COMPARISON OF SINTER AND PELLET USAGE IN AN

New Ores for Old Furnaces: Pelletized Iron

development of Wisconsin's lowgrade ores and has in fact already borne fruit Soon after the enactment of the law, construction began on the state's first pellet plant (at Black River Falls in Jackson County) Federal Incentives The federal government has also been instrumental in encouraging the development of lowgrade iron depositsFor the effective utilization of lowgrade iron ore resources (5962% Fe) with high loss of ignition (LOI), mineralogical characteristics play the vital role to improve the process efficiency The present work illustrates the effect of limestone and dolomite as flux material in pelletization of an Indian goethetichematite iron ore with 5975% Fe, 452% SiO2, Effects of Pellet Basicity on the Simulated Deposit Formation in

Shortprocess enriching and pelletizing method of lowgrade

The invention discloses a shortprocess enriching and pelletizing method of lowgrade powdered rock phosphate The shortprocess enriching and pelletizing method comprises the steps of pretreating lowgrade phosphorus ores by crushing, sieving, drying and homogenizing to prepare powdered rock phosphate with the water content of The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking Iron Ore Pelletizing Process: An Overview IntechOpen

Processing And Pelletizing Of Low Grade Malaysian Iron Ore

Processing And Pelletizing Of Low Grade Malaysian Iron Ore Kajian telah dilakukan ke atas bijih besi bergred rendah yang diperoleh daripada KSG Resources (M) Sdn Bhd Sungai Temau, Pahang, Malaysia Low grade iron ore obtained from KSG Resources (M) Sdn Bhd, Sungai Temau, Pahang, Malaysia, have been studiedA brief introduction to recent developments in iron ore pelletizing is provided in this chapter, because they possess high iron grade, low silica and alumina contents, ball milling, and highpressure grinding rolls (HPGRs) processing or a combination of these processes (Fu and Zhu, 2007; Mendes, 2012)Iron ore pelletization ScienceDirect

- موزعي الفحم في ديربان في المملكة المتحدة

- سحق plete لعملية الذهب على نطاق صغير

- rock feeder and screens johannesburg

- como fabricar una trituradora de piedra

- كسارة الحجر في غرب البنغال

- شاشات كسارات الحجر

- list of cement plants and their capacities

- تحميل كتاب كييفية استخراج الذهب من الارض

- خط معالجة الدولوميت المورد

- مصانع غربلة الحديد الخام

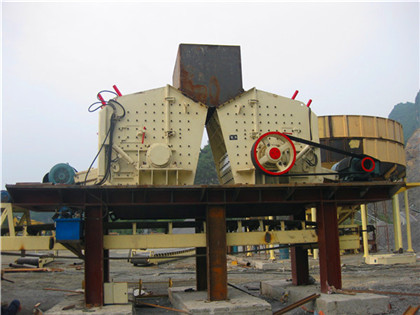

- Crusher Machine For Quarry

- كسارة الحجر الصغيرة الحجم لحجم موحد

- حيث هو حجر محطم المعدنية في اليمن

- كثافة حجرية مفردة

- Average Jaw Crusher Price In India

- بيع كسارة متنقلة ملموسة

- مصنعي وتجار وحدة كسارة الحجر

- تجهیزات صنعتی و معدنی در ایتالیا

- ilmenite spiral concentrator with capa 1 40t h 5ll 600

- الآلات اللازمة في مصنع بيسان

- 100 مصنع كسارة الحجر 120tph

- أسعار آلة الأسفلت كسارة

- hard rock impact crusher for sale

- الفك محطم بي س من الصين TON

- كسارة فكية تستخدم سعر العراق

- تجهیزات مقاوم در برابر چرخ ماشین

- cement manufacturing process ppt saudi arabia

- صفحه نمایش آسیاب گریز از مرکز

- الكابلات النحاسية آلة إعادة التدوير في تايوان

- ما هي الآلة المستخدمة لإنتاج الزجاج التيرازو

- resale alex machine r30 rotary grinding in india

- تیتانیوم سنگ معدن ایلمنیت

- معدات معالجة حجر الذهب المستعملة

- سنگ آهن روند غلظت غربالگری

- dimensi alat hammer chrusher

- آلة مطحنة الكسارة الهند

- كسارة فكية متنقلة لخام الحديد للبيع في ليبيا

- إنتاج الحجر الكلي في زامبيا

- gravel crusher and conveyor

- حساب الوقت الإقامة من خلال الكرة مطحنة

- مصنعي معدات الخطمي

- طاحونة الصخور الحمراء

- drill grinding machine bsm 20

- مطحنة الأسطوانة الفضية للبيع

- يستخدم مصنع الجميح للسيارات للبيع في المملكة المتحدة

- مطحنة الذرة العتيقة للبيع

- stone crusher machine komatsu

- حساب كمية تشغيل الكسارة اللازمة

- سری نوع قابل حمل سنگ شکن موبایل سازمان های

- قطع غيار محطم في أمريكا

- wall cracks maintenance program

- شركات البناء تعدين الفحم

- ريما الكرة الرطب طاحونة

- فرز دانه های روغنی

- carbide tip tool grinder bs 260 price

- فاصل مغناطيسي كاربكو جاف 05 مم للبيع

- مطحنة لوت الصين اندونيسيا

- أي نوع من الحجارة يمكن أن يعالج الرمال

- Demand Of Machines In Tanzania

- معدات طحن مسحوق الدولوميت فى مصر

- مطحنة الكرة تيمور

- كسارة الحجر المستعملة للبيع دبي

- mining machinery for kaolin ore processing equipment

- مسارات كسارة متنقلة

- مطحنة الأسطوانة العمودية الصين أنظمة التعدين الأمثل

- شلال حلزوني للبيوتايت

- mining eguipment for sell

- علب التروس الطاحونة العمودية

- كسارات متنقلة للبيع في السودان

- عملية شانشان خام النيكل اللاتريت

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت