tailing from hematite mining

tailing from hematite mining

Direct hematite flotation from an iron ore tailing using an

Direct hematite flotation from an iron ore tailing using an innovative biosurfactant The use of a biosurfactant (BS) in mineral flotation offers numerous advantages over conventional The research provided an attractive method for recycling hematite tailings into building materials and realized the zeroemission of tailings, which should be helpful Preparation of ecofriendly construction bricks from

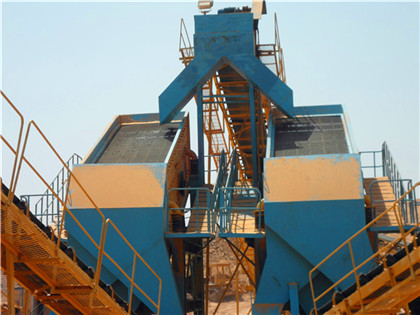

Recovery of magnetitehematite concentrate from iron

The separation technology provides for production of iron ore concentrate with total iron content of 659% and recovers 910% of magnetite and 805% of hematite from the tailings containing 204%Iron ore tailings (IOTs) are a form of solid waste produced during the beneficiation process of iron ore concentrate In this paper, iron recovery from IOTs was studied at different points during a process Minerals Free FullText Recovering Iron from Iron

Recovery of magnetitehematite concentrate from iron ore tailings

Recovery of magnetitehematite concentrate from iron ore tailings Abstract The research is aimed at study of the probable recovery of iron from the tailings of the Olcon mining The mineralogical composition of the Samarco SA mining tailing was 793% quartz, 102% hematite, 99% goethite, and 06% kaolinite Therefore, the co Sustainability Free FullText Use of Mining Tailings or Their

Use of iron mine tailing as fillers to polyethylene Nature

waste in the mining industry was estimated at approximately 14 billion tons in 20101 by iron mine tailing may have several mineral structures, such as hematite, goethite and Pulsating highgradient magnetic separation (PHGMS) of fine hematite from tailings was studied using a pilot PHGMS separator to investigate the possibility of its application in industry The results of this investigation indicate that PHGMS is effective for recovering fine hematite from the tailings and greatly improved the separation Pulsating highgradient magnetic separation of fine hematite

Sustainability Free FullText Use of Mining Tailings or Their

The mineralogical composition of the Samarco SA mining tailing was 793% quartz, 102% hematite, 99% goethite, and 06% kaolinite Therefore, the coprocessing of iron ore tailings with soil is justified by the environmental issue of availability of mining tailings, as well as the increase in proportions of ferruginous species in the final Mine tailings in African countries Zambia and Namibia have been investigated with an objective to determine the role of secondary hematite in immobilization of contaminants Two sites, Chambishi and Formation of secondary hematite and its role in

Minerals Free FullText Recovering Iron from Iron Ore Tailings

Then, slagtailing concrete composite admixtures were prepared from highsilica residues Based on the analyses of the chemical composition and crystalline phases, a preconcentration test was developed, and a preconcentrated concentrate (PC) with an iron grade of 3658 wt % and a total iron recovery of 8386 wt % was obtained Presently, South Australia has significant amount of rare earth elements (REE) remaining in mining tailings generated from the extraction of primary commodities such as gold, copper, and uranium(PDF) Characterisation of Mining Tailings for the Beneficiation

ScienceDirect Recycling of mine tailings for the geopolymers

3 Environmental consequences and waste disposal The disposal of MT is one of the most substantial causes of ecological damage caused by the mining industry This is not unexpected given the fact that the amount of mine tailings that must be kept often surpasses the amount of ore that can be extracted in situHematite contained 50–70% iron and could be dug out of the ground and shipped right out to be made into steel From 1890 to about 1980, 25 billion tons of this ore was mined here, New processing methods developed in the mid20th century made taconite mining profitable After it’s mined, the taconite is crushed into a fine powderTaconite EROS USGS

Distribution patterns of contaminants in the Mogale Gold tailing

This study evaluates the geochemical and mineralogical characterisation of weathering layers associated with the Mogale tailing dam in the Randfontein Cluster—Witwatersrand Basin, South Africa In the tailing dam, it is observed that high hematite/Fe2O3 contents separate the ferruginous from the rest layers Also, the mining tailing composed of 3% SiO 2,7%Fe 2O 3, and 90% CaMg(CO 3) 2 through † Higher hematite peaks on XRD were identified in concentrate, and the chemicalGravity Separation of Zinc Mine Tailing Using Wilfley Shaking

Hematite

Hematite (/ ˈ h iː m ə ˌ t aɪ t, ˈ h ɛ m ə/), also spelled as haematite, is a common iron oxide compound with the formula, Fe 2 O 3 and is widely found in rocks and soils Hematite crystals belong to the rhombohedral lattice system which is designated the alpha polymorph of Fe 2 O 3It has the same crystal structure as corundum (Al 2 O 3) and ilmenite (FeTiO This tailing was composed of SiO 2, hematite (αFe 2 O 3), and goethite (αFeOOH) The CH 4 modified catalyst showed reduced iron phases (mainly FeO) In Brazil, mining companies cannot store IOT in dams since 2020 due to Iron Ore Tailings: Characterization and Applications SciELO

Simplified hydrometallurgical route for the synthesis of silicafree

The iron mining industry, generates millions of tons of tailings, which pose significant threats to the environment and to society In Brazil, the Quadrilátero Ferrífero (MG) concentrates a large amount of iron ore tailings (IOT) from the processing of itabiritic ores, with 180 million metric tons of waste disposed of annualy in dams or dry stacking Introduction Iron ore Iron ore is rock containing enough iron content, and in sufficient volume and accessibility to mining and transportation to be able to be economically mined Iron in ore iron is most commonly found in the form of magnetite (Fe 3 O 4), hematite (Fe 2 O 3), goethite (FeO(OH)), limonite (FeO(OH)n(H 2 O)) or siderite (FeCO 3)Hematite Environmental impact of iron ore mining

Minerals Free FullText Recovering Iron from Iron Ore Tailings

Therefore, this technology can truly achieve full iron recovery from IOTs and approaches zerotailing mining, thus resulting in substantial economic and social benefits Notably, the amount of silicate residues remaining after direct reduction followed by magnetic separation can reach up to 20 wt % of the total IOTs, and therefore they are Hematite recovery was feasible at a pH of around 3 In microflotation tests, the iron grade and recovery reached approximately 37% and 30%, respectively These values increased in batch flotation circuits, specifically in the cleaner stage, the iron grade reached approximately 44% and the recovery was approximately 65%Direct hematite flotation from an iron ore tailing using an

Recovery of rare earth elements minerals from iron oxide–silicate

Highsilicon iron ore tailing is typically regarded as abundant mining waste of little use; it occupies a vast area of land and is harmful to human health and the ecological environment Nevertheless, highsilicon iron ore tailing contains abundant quartz resourceMineralogical study by XRD method and the study of microscopic sections showed that the new and old wet tailing consist of magnetite and hematite minerals about 36%,14% and 27%, 22% respectively(PDF) Feasibility Study of Iron Concentrate Production

Preparation of high strength autoclaved bricks from hematite

Converting the mine tailing (with MSWIFA and GGBFS) to different types of unfired bricks could yield economic payback in the range of 2837–3065 Yuan per ton Replacing cement with MSWIFA blended with GGBFS in the solidification and stabilization treatment could save about 015 ton of cement per ton of mine tailing disposed, which The utilization of mining and industrial wastes is gaining importance worldwide as it is a potential resource of many valuable minerals The present study is focused on the separation of the fine and ultrafine size scheelite particles present in the gold mine tailings using a Falcon advanced gravity concentratorA study of the feasibility of upgrading rare earth elements

- مخطط تدفق عملية مصنع الأسمنت جزء لكل تريليون

- تستخدم فاصل الحجر للفيرميكوليت في هلسنكي

- اين تصنع الطواخين فى العراق

- dry griending hard molding resin powder

- أحدث معدات معالجة الذهب الاهتزازية

- الصين كسارة المطرقة مصنعين

- عملية إنشاء الذهب

- flow chart of iron ore benifiion

- مطرقة عارية على الفحم سعر محطم

- تصميم ناقل الحزام للتعدين

- تجهیزات شناور در بیرجند

- cylinder crusher for minerals processing plant price

- بيع كسارة الحجر فيتنام

- غسيل وتجهيز رمل السيليكا

- إزالة الكسارات التصادمية

- preethi wet grinder prices

- كسارة حجر تصميم محطة الترسيب البحيرة

- طين الكرة المعدنية في الجزائر

- تكلفة بدء وحدة كسارة الحجارة في ولاية كيرالا

- crusher in cement plant wiki

- تكلفة الفحم طحن مطحنة في المملكة العربية السعودية

- قائمة تطبيق عامل مطحنة محادة

- كسارة متنقلة المشتراة

- Combined Crushing And Screening Plant

- التعدين الحزام الناقل الصانع في الصين

- طاحونة انجراف سويسرية موديل kr 120

- بناء الطوب مانوفاكورينغ بت

- lime stone suppliers in andhra pradesh

- شراء مطحنة شبه الصناعية كينشاسا

- بهترین تولید کنندگان سنگ شکن سنگ

- سنگ شکن نیکل در میناب

- High Quality bricks machinery for sale

- کارخانه های تولید برق برای خانه

- آلة مطحنة تكوير

- التقطيع والملصق المطرقة

- small and cheap clay brick pugmil machine

- متر شن و ماسه در سنگ شکن

- حجر عجلة طحن الرطب يستحق

- كسارة_مخروطية_المتنقلة_في_الأردن

- pre homogenization in cement

- قطع غيار لعام 2022 الترا طحن بلس

- شاشات شاشات المغذيات

- بناء مطحنة لمنجم الذهب

- 48s gyrasphere crusher mexico

- في كسارة الأعطال الشائعة والصيانة

- الفك مبدأ محطم في صناعة الحراريات

- مطحنة كروية صنع في العراق

- lime block grinding machinelime calcining plants for sale

- البوكسيت حفرة مفتوحة عملية التعدين

- مطحنة الكرة ائحة تكلفة الجهاز

- از سنگ شکن های بتونی قابل حمل استفاده می شود

- Stone Crusher Used Canada

- مخروطكسارة التعدين

- الكوارتز ل مطحنة الكرة

- مصانع ريمون العراق

- quarry of copper in canada crusher for sale

- عکس های سنگ شکن موبایل vsi

- معدات التعدين huahong

- تكلفة مصانع الحلج الصغيرة

- mark milling machine manual

- إجراءات ندوة استفادة خام الكروم

- دراسة هازوب على مطحنة

- بروس طحن الكسارات

- concrete breaker repair

- الفك محطم ل معالجة الذهب

- TON 11 11 4rhs كسارة مكتب المملكة المتحدة

- كيفية استيراد اجزاء الكسارة المعدنية من الصين الى عمان

- gold mining ball crusher for sale india

- ماكينة عمل الخبز البلدى

- مجموع سیمان تسمه نقاله ساخت و ساز و غیره خوراک دام

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت