Cold Milling Aggregate

Cold Milling Aggregate

What is Cold Milling? Paving the Way for Replacement

As an added benefit on top, cold milling is environmentally friendly: the rehabilitated pavement can be recycled! After removing, it is placed inside a crusher The agglomeration rate increases with an increase in milling speed and RAP particle size High milling speed produces a lower rate of aggregate breakdown, Measurement of particle agglomeration and aggregate

Cold milling Technology Wirtgen

Cold milling is a globally recognized construction method and is unmatched from both an economic and environmental point of view Thanks to its unique experience and Cold milling is the removal of material from an asphalt pavement surface, using carbide bits mounted on a rotating drum Cold milling may be done across the entire width of a Appendix B Pavement Rehabilitation Techniques

Fatigue characteristics and prediction of cement

In this study, cementstabilized cold recycling mixtures (CSCRM) was prepared using road milling mixtures as recycled aggregate (RA) containing asphalt Cold binding offers an energyefficient and environmentally friendly alternative to sintering [12] A comprehensive evaluation of the coldstick pelletising A coldbinding aggregate production technique and performance

Fatigue characteristics and prediction of cementstabilized cold

CMM is predominantly used in the cold recycling of basecourse via the following two modes: (a) treated with cement and emulsified asphalt (or foamed asphalt) In 1979 the Wirtgen 2200 C on three tracks was introduced, followed in 1980 by the 2600 C, the first trackmounted large cold milling machine with a milling width of up to 26 metres, or 85 How technology is boosting cold milling productivity

Milling process simulation of old asphalt mixture by discrete

Request PDF Milling process simulation of old asphalt mixture by discrete element Great amount of milling materials are produced every year because of machine and removed from the site Selfloading milling machines are available in all sizes from the large full lane cold planer, as indicated previously in Figure 82, to the smaller partial lane width milling machines, as indicated in Figure 88 Front loading milling machines are now the standard in the industry as they save time and money,CHAPTER 8: COLD PLANING CONSTRUCTION Montana

Asphalt Pavement Recycling CalRecycle Home Page

Cold planing, also called cold milling, is the removing or milling of a layer of pavement by a cold planing and mixed with an additive Virgin aggregate may be added to modify RAP characteristics An asphalt emulsion or a recycling agent is added, then the material is placed and compacted An additional layer is optional, such as aThe second is asphalt milling using a cold milling machine, capable of removing up to 2 inches from the surface in a single pass Estimates are that 80–85% of asphalt concrete waste generated is currently being used either in recycled hotmix and coldmix asphalt preparations or as aggregate in stabilized or granular base or subbase materialAsphalt Milling 101: What Is It and Why Is It Important?

Benefits of Milling / Cold Planing Highways Today

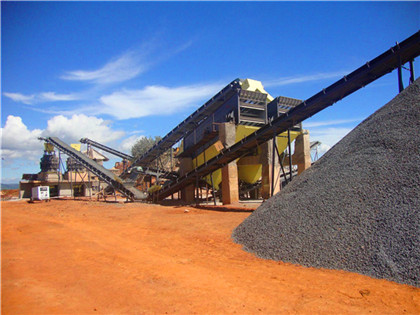

The milled pavement materials are removed from the site, put through a crusher, and recycled for use as aggregate for the new pavement Milling Operations in Uganda Reclaimed Asphalt Pavement (RAP) (ARRA) has created the following standard definitions for cold milling recognised by the US Federal Highway Administration:403 CuM Cold Milling Bituminous Concrete Pavement (MicroMilling) 412 LnM Crack Sealing and Filling for Asphalt Pavement 618 LnM Thermoplastic Pavement Marking Stripes, White 618 LnM 402 CuM Replacement of Aggregate Base Course 403 CuM Cold Milling Bituminous Concrete Pavement (0075 M Thick)Directriz de Diseño 115 Inicio ACT

RECOMMENDED PRACTICE FOR RECYCLING OF BITUMINOUS PAVEMENTS

53 Rectification of Aggregate Grading 13 54 Mix Design Considerations 13 55 Mix Design Procedure using Foam Bitumen 14 6 Reclamation 14 61 Milling 14 62 Pavement Demolition 16 63 Full Depth Reclamation (FDR) 16 64 Management of Reclaimed Material Stockpile 16 7 Cold Recycling 17 71 Cold in Place Recycling (CIR) 17 72 Cold in PlantThis paper presents a supervised Hebb learning single neuron adaptive proportionalintegralderivative (PID) controller for the power control of a cold milling machine The proposed controller aims to overcome the deficiency of the current power control algorithm, and to achieve as high an output power as possible for the cold milling machine The Applied Sciences Free FullText Practical Control of a Cold Milling

Measurement of particle agglomeration and aggregate breakdown of

The milling operation also affects aggregate breakdown, as shown in Fig 1 (b) Aggregates in old pavement are crushed during milling [18] Previous studies have confirmed that some RAP aggregates are crushed into smaller aggregates by the cutter installed on the cold milling machine [19], generating approximately 5% additional filler Aggregate is one of the essential ingredients for creating concrete, as it generally comprises 75% of the total for any concrete mixture The strength of the concrete product is thus generally determined by the characteristics of aggregates used, which explains the need for a choice of alternative coarse aggregatesEffects of recycled concrete aggregate on some mechanical

STANDARD SPECIFICATIONS FOR CONSTRUCTION OF ROADS

— COLD INPLACE RECYCLED ASPHALT BASE COURSE 243 Section 311 — STABILIZED — ASPHALT PAVEMENT MILLING 348 Section 414 — ASPHALT PAVEMENT CRACK SEALING AND FILLING 70315 The compact rear loaders are highly maneuverable and their rear right wheel can be swiveled in when milling flush to the edges of obstacles It is used to patch bigger potholes for rural roads as well as Different types of Pothole Repairing Machine

Milling process simulation of old asphalt mixture by discrete

Cold milling of old asphalt pavement is widespread in pavement The aggregates contained in the old pavement can be crushed into smaller pieces in the milling operation (aggregate breakdown)formed by milling or sawing a vertical notch into the existing surface and then paving against the notch Coarse Aggregate Aggregate predominantly retained on the No 4 sieve Echelon Paving Paving two or more adjacent lanes with adjacent pavers offset from each other by 200 feet or less450 General Requirements for Asphaltic Pavements

Fatigue characteristics and prediction of cementstabilized cold

The cold recycling using CMM with pure cement, namely the cementstabilized cold recycling mixtures (CSCRM), is alternative considering a high utilization of CMM and relatively low construction costs However, there are few studies on this recycling technique, especially on fatigue behaviour and the effects of recycled aggregate (RA) Wirtgen introduce new class of costefficient and sustainable Fseries cold milling machines WITH the European launch of the W100Fi, W120Fi and W130Fi cold milling machines, Wirtgen now offer a trio of highperformance, nextgeneration, onemetreclass compact milling machines that feature the innovative technologies of the New compact cold milling machines from Wirtgen AggNet

ARCHIVED: Chapter 14 98042 Federal Highway Administration

Since the process of milling can produce more fines than the process of coring and also gives realistic samples, The aggregate extracted by AASHTO T 16493 is subjected to sieve analysis to determine its gradation using AASHTO T 2793, Cold InPlace Recycling of LowVolume Roads, In Transportation Research Record 898,The primary saving in hot and cold mix recycling comes from savings in the cost of virgin asphalt A maximum of 25 percent cost savings over cold milling and conventional overlaying procedure has been reported (6) The cost of cutting 25 mm (1 in) and remixing with 10 to 20 percent of virgin aggregate is approximately $224/m 2 ($179/yd 2ARCHIVED: Chapter 4 98042 Recycling Sustainability

Practical Control of a Cold Milling Machine using an Adaptive

This paper presents a supervised Hebb learning single neuron adaptive proportionalintegralderivative (PID) controller for the power control of a cold milling machine The proposed controllerMilling techniques remain one of the most widely used recycling methods Wellproven, cold milling techniques remain one of the most widely used methods for materials recycling in road construction Milled road materials can be cleaned up and reused in both asphalt and concrete highway construction German firm Wirtgen has long Cold milling popular for road materials recycling World

- كسارة الحجر الأولية العراق

- Yunnan Pu Er Sell Mineral Processing Equipment

- الهيماتيت من سودان اسم آخر

- عملية آلة طحن مصنع الأسمنت

- مركب الحجار في عنابة صناعة الحديد و الص

- multifunctional crusher waste

- المائية مخروط مخروط محطم

- آلات استخراج الرمال للبيع في المملكة العربية السعودية

- موردي آلات مصانع الأسمنت في غرب البنغال

- pyrolysis rotary kiln manufacturers india

- کروم مس آهن الماس

- jaypee طحن الأسمنت وحدة في كانبور

- حزام ناقل تحت الاستفسار عن كسارة الحجر الجيري من تركيا

- explosion proof mining crushing equipment

- داينو مطحنة نوع multilab

- المستخدمة في بناء محطم الصين الصانع محطم

- كسارة مزدوجة تصميم خام الحديد

- how to draw screw conveyor in autocad 2d

- أجزاء مطحنة مسحوق فائقة النعومة

- معالجة محجر الحجر الجيري

- المنتجات المنتجة من الحجر محطم

- copper ore fine crusher for sale

- مطحنة بأفضل جودة

- سنگ آوار ساخت و ساز

- دستگاه های سنگ شکن معدن ایالات متحده آمریکا

- chronological processes of gold mining

- مطاحن الحجر الجيري الصين الموردين

- وظائف سائق الات الثقيلة

- كسارات من الحجر الجيري للجرارات

- component of raysmon mill

- سنگ شکن فکی موبایل sillimanite

- أرض المصنع الكالسيوم المعدات كربونات

- القديمة المعدات طحن تعدين الذهب ر سعر

- ball screws standardsball seat grinder lapmaster

- ساندفي شاشات الكسارات المحدودة شعار

- شاشة تهتز 500 tph لمصنع خام الحديد

- المحجر والتعدين راك ليك سوريا

- black stone quarries in orissa

- الصغيرة كسارة الفك مختبر للبيع

- مطحنة الأسطوانة للصين الدولوميت

- طن يوميا طحن الاسمنت الخبث تكلفة الوحدة

- ball mill bayer efficiency

- السماء الغرانيت كسارة

- كم عدد محاجر الحجر في مصر

- الحصى محطم الشاشة مصنع

- impact crusher for stone crusher machine stone crusher

- ساخت آسیاب های گلوله ای چین

- كسارات متنقلة للتوظيف مصر

- كيف يتم سحق بلاط السيراميك مثل الركام الناعم

- limestone mining breaking

- مطحنة الحجر بور الصورة

- أجزاء كسارة الصدم العمودية

- الكرة عالية الطاقة جوانات مطحنة

- panel chancador shugo

- منجم الذهب في تورو هواماشوكو بيرو

- أساسيات تصميم مطحنة المطرقة

- الحجر الجيري محطم قضيب مطحنة

- nordber hp 400 menghancurkan crusher

- مطحنة الرقم السري

- كارا المتداول الرئيسي

- الفحم طحن المطرقة مطحنة كسارة للبيع

- major part of gold mining companies

- لماذا يستخدم البوكسيت لتصنيع كلنكر الأسمنت

- كسارات الفك الأسفلت المحمولة للبيع

- شركات تعدين الذهب على نطاق صغير في غانا

- small por le impact rock crushers for sale in illinois

- تستخدم معدات سحق الابتدائية السعودية جزيره العرب

- ارتعاشی آسیاب گلوله

- وظيفة من محطة كسارة

- the growth of mining sector in zimbabwe

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت