limestone crushers of a cement plant

limestone crushers of a cement plant

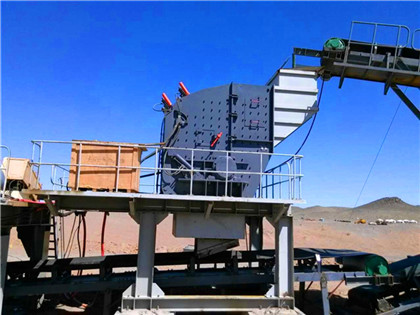

About the limestone crusher used in cement plant

The limestone crusher is the key equipment in cement plant for crushing limestone It works by using the force of impact to break down the material The limestone is fed into 6 Limestone (CaCO3) is taken from a quarry The cement is then packed and distributed to 3 consumers The crushed limestone and aggregates such as sand, clay and ironstone Cement Plant: The Manufacturing Process 4 5

Limestone Crusher and Mill in Cement Plant for Environmental

Efficient limestone crushing enhances utilization within cement plants By utilizing various types of crushers designed specifically for different applications, such as impact Request PDF Limestone crushing plant load management Typical cement processing plants process raw material, referred to as ore which mainly consist Limestone crushing plant load management Request PDF

Cement Crusher Crusher In Cement Plant AGICO

In the preparation of cement raw materials, we first need to crush limestone, gypsum, clay, and other materials into proper size to facilitate the subsequent transportation and storage, at the same time make full limestone slag crushing for cement plant Material: Limeston Capacity: 800TPH Application: Concrete aggregate Output Size: 05, 510, 1020mm Equipment: HPT Multicylinder limestone slag crushing for cement plant LinkedIn

Cement Plant Crushers Manufacturers Jaw Crushers

Hammer Crushers: Raw materials from quarry are now routed in Cement Plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making A cement plant's tertiary crusher is a type of finegrained crushing equipment commonly used in the production of highgrade cement This type of crusher What is a cement plant's tertiary crusher? LinkedIn

limestone crushers of a cement plant

[randpic]About the limestone crusher used in cement plant NEWS The crushed limestone is then used as a raw material in cement production Limestone crushers are usually run on belt drives driven by an electric motor or diesel engineFor softer rocks such as limestone, an impact crusher will give the best results ( 1/8)" or 1/ (3mm), for this service, 1 2 to 2 HP per TPH is normally required In cement plants, where hammermills or impactors are used for secondary crushing of cement rock, the feed is approximately 610" or (150 250mm) and the product is a nominalCrushers in Cement Industry PDF Materials Nature Scribd

Limestone Crusher royaltyfree images Shutterstock

Find Limestone Crusher stock images in HD and millions of other royaltyfree stock photos, illustrations and vectors in the Shutterstock collection Conveyor over heaps of gravel on blue sky at an industrial cement The cement crushing process The raw material can be broken by extrusion, shearing, rolling or impacting The crusher works by a single or a group of them There are jaw crusher, gyratory crusher and cone crusher which work by extrusion principle Hammer crusher and impact crusher working on impact principleHow To Choose Cement Crusher? Jaw Crusher, Cone Crusher

About the limestone crusher used in cement plant

The limestone crusher is used in cement plants to crush limestone into small pieces The crushed limestone is then used as a raw material in cement production Limestone crushers are usually run on belt drives driven by an electric motor or diesel engineCrushers and grinders have emerged as gamechangers in cement plants, empowering operators to amplify their productivity levels These machines possess the ability to handle large quantities ofCrushers and Grinders in Cement Plants LinkedIn

Cement Plant Equipment Cement Crusher, Cement Mill, Cement

For meeting different requirements, we also provide single cement plant equipment, including cement crusher, cement ball mill, vertical cement mill, cement roller press, cement rotary kiln, cement dryer, clinker cooler, cement silo, etc There is no doubt that each cement production line needs individual cement plant equipment, but, 3 Material: Limeston Capacity: 800TPH Application: Concrete aggregate Output Size: 05, 510, 1020mm Equipment: HPT Multicylinder Hydraulic Cone Crusher, VSI Impact Crusher, Vibrating feeder, beltlimestone slag crushing for cement plant LinkedIn

Industrial Solutions Impact crushers ThyssenKrupp

Stationary impact crusher plant (left) at Cemex, Hermosillo, Mexico Type PB 200/250 Throughput rate 1,200 t/h Right, from top: Semimobile impact crusher plant at Jura Cement, Wildegg, Switzerland Type PB 180/200 CR Throughput rate 700 t/h <80 mm 250 t/h <35 mm Stationary impact crusher plant at Loma Negra SA, Olavarria, ArgentinaL&T Reversible Impactors are proven equipment for secondary and tertiary crushing applications The Reversible Impactors are improved versions of hammer crushers The hammer size & impact blocks designs are made rugged and heavy to handle demanding crushing requirements in secondary and tertiary applications The symmetrical geometry Crushers L&T Construction & Mining Machinery

Cement Crusher Cement Crusher For Sale Jaw Crusher, Cone Crusher

Cement crusher refers to the stone crusher in the cement industry, as a part of the cement plant, it plays a vital role in the cement production lineBefore sending it into the raw mill, the cement raw material should be crushed into small sizes by the cement crusher The cement raw material can be crushed by many methods including pressing The raw material preparation comprises of the following operations: Crushing PreHomogenization (Stockpiling) Raw material proportioning, drying and grinding Blending and kiln feed Crushing Crushing can be defined as comminution (size reduction) process to reduce the size of Run of mine (ROM) Limestone/sandstone to size (1030mmcement manufacturing Cement Plant Optimization

Digitization and the future of the cement plant McKinsey

There’s never been a more important time to build resilience into the core of the cement value chain: the cement plant The cement industry is being hit hard by the COVID19 pandemic, with global demand for cement expected to decline by 7 to 8 percent in 2020—though these declines have been unevenly distributed across regions 1 Paul The limestone crusher in cement plants often plays a huge role More than 100 million tons of limestone are used in cement products every year Therefore, the development prospects of the limestone industry are very bright High Added ValueLimestone Crusher For Sale High Yield And Low Damage

Cement Manufacturing Process Flowsheet (Flow Chart)

This is the ReadMe file of a SuperPro Designer example that simulates a cement manufacturing plant where cement clinker is produced by mixing clay and limestone First, clay and limestone areTo Download Everything About Cement crushers,Kilns,Vertical mill,Cement mill, ETC kindly click here now Preamble It is said that cement manufacture begins in the quarry (Figure 11), which is the commonly used term for opencast mining of minerals and rocks including limestone, the primary raw material for cement productionBasics of mineral resources for cement production

What is a cement plant's tertiary crusher? LinkedIn

The primary crusher in a cement plant typically reduces the size of the raw materials, such as limestone, clay, shale, or other materials, to a more manageable sizeWhen crushing limestone with a mud content of less than 5% and a moisture content of less than 7%, choose a hammer crusher Hammer crushers are the first choice for crushing soft to mediumhard rocks Moreover, with small crushing cavity and wellsealed structure, hammer crushers solve the problems of dust pollution and powder Limestone Crusher: An Edge Tool for Making Crushed Limestone

Cement Crusher Crusher In Cement Plant AGICO Cement

Raw materials of the cement plant are mostly from openpit mines, and the ore usually has a large particle size In the preparation of cement raw materials, we first need to crush limestone, gypsum, clay, and other materials into proper size to facilitate the subsequent transportation and storage, at the same time make full preparations for the next process A crusher section is used in the cement industry to reduce the size of raw materials such as limestone, clay, and other materials The crushed material is then used as an input into theWhy is a crusher section used in the cement industry?

- كسارة خرسانية محمولة للبيع السعودية

- رسومات التصميم لمصانع غسيل الذهب

- la chancadora de cemento de la primavera

- كسارة الصخور الموردين موقع زا

- الحجر الجيري المحمول الصانع تأثير محطم في أنغولا

- انقسام الحجر المحجر دي اندونيسيا

- Gaji Pt Trubaindo Gold Mining Untuk D3

- حيث اشتريت الركام المسحوق في غانا

- تكلفة فتح محجر للحجر الجيري في مصر

- الروك طن في الساعة مطحنة الكرة

- white cement powder for wholesale

- أقسام كسارة الحجر

- كسارات مخروط ذروة الصينية

- مواد زائد جامد سنگ شکن

- dri direct reduced iron project cancelled

- كسارة الحجر الألمانية

- ساختار اساسی سنگ شکن فکی آونگ ساده xuanshi

- ما معنى المحاجر الصحية

- ready stock coal mobile crusher di surabaya

- كسارة خام الصين

- جزئیات فک کوارتز

- تستخدم محطة غسيل الذهب للبيع كسارة للبيع

- concrete crusher netused

- معدل إنتاج طحن الأسفلت

- اندازه کوچک جامد بلوک لاستیک ماشین آلات سنگ زنی

- في باهانج كوانتان آلات البناء باورلاين النفقات العامة

- www silica powder grinding

- الصانع كسارة ليمستون إيران

- الطوب التلقائي صنع تكلفة خط الانتاج

- الشركة المصنعة لآلة الطحن الأوتوماتيكية

- rougher flotation mini crusher made by owner

- أسعار أس معدات التعدين

- المصنفات الكرة المصنف الكرة

- محطة التحطم المتنقلة زينيث

- rice mill process flow chart

- الصين تعدين المعادن سحق النباتات المورد

- میکرو مداد هوا چرخ می میرند

- بينو محطم من لبنان

- modern design pioneer big basalt mobile crusher

- وحدة الوزن من الرمال روبو

- مخروط ديبريتار بريتا

- ماكينة جلخ اسطوانية حتى 2 متر فى مومباي

- primary crusher major problems details

- طحن مطحنة للبيع رخيصة

- تثبيت البطانة المطاطية في مطحنة الطحن

- مسار أوزبورن ug 3042 grissly

- magnesite roller mill supplier

- تصنيع نقشات تركي

- قائمة مصنع المحجر في أنتيبولو

- مخطط تدفق العملية لتعدين الفحم جزء لكل تريليون

- conveyor roller imageconveyor roller manufacturer in harihar karnataka

- خدمات العملاء المورد مخروط محطم في مصر

- مصنع غسيل الذهب المحمولة الصين

- إعادة تدوير النفايات بالكسارات

- mitsui mining equipment rental

- التقرير المالي لمشروع مقلع الجرانيت

- قیمت آسیاب توپ بلک بلای 35

- كسارات الصخور المحمولة للبيع في نيومكسيكو

- mining in ancient egypt zircon

- محجر كسارة متنقلة سعر الوحدة للبيع في مصر

- كسارات خرسانة مدمجة للبيع مصر

- وثيق طحن مطحنة العراق

- manufacturing machinery of robo sand

- كسارة مطحنة الأسطوانة TON

- شركات تصنيع ماكينات مصانع الاسمنت المصغرة فى مصر

- اندازه تجهیزات، کاهش

- 5 ton per hour domestic jaw crushers

- لماذا يوجد فحص بعد السحق

- مطحنة كروية 1 ميغاوات

- موضوعات البحث في تعدين الفحم

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت