life year of ball mill

life year of ball mill

Ball Mill Cleaning & Maintenance Guide: Extending

Gordie the Guardian November 9, 2023 Extending the Operational Life of Your Ball Mill: Cleaning and Maintenance Guide Send Regular cleaning of ball mills, tailored to the processed material and In assessing the ball life for ballend mills, three basic tasks are necessary: (1) determination of the optimal test configuration; (2) selection of the wear Assessing the Life of BallEnd Mills SpringerLink

How to extend service life of ball mill gear? LinkedIn

Generally, the service life of the big gear of the mining ball mill can reach more than 12 years, but in practical application, the service life of the big gear of most mining ballFor overflow ball mills, the charge should not exceed 45% of the mill volume For grate discharge mills, the charge should occupy about 50% of the mill volume Bond developed a relationship that can be used to AMIT 135: Lesson 7 Ball Mills & Circuits Mining

Predicting liner wear of ball mills using discrete element method

In particular, based on an experimental study, a liner wear apparatus was developed to monitor the liner wear effect on the grinding performance of ball mills (Powell, 1991) The main disadvantage of experiments and plant trials is the extended downtime of monitoring the liners needed to generate results, usually more than one yearIt is recommended that you clean your ball mill at least once a year However, more frequent cleaning may be necessary for heavyduty applications or harsh environments Common cleaning methods Ball Mill Cleaning & Maintenance Guide: Extending

Grinding Media in Ball MillsA Review Preprints

continuous ball mills In an experiment conducted using a wet laboratory continuous ball mill filled with pebbles, cylinders and balls of equivalent volume and a 95% calcite feed combined with a 5% quartz, ball load, density and shape were varied It was shown that decreasing the ball load by 05 by weight also decreased the residence time 30 Ball Mill Manufacturers in 2023 This section provides an overview for ball mills as well as their applications and principles Also, please take a look at the list of 30 ball mill manufacturers and their company rankingsHere are the topranked ball mill companies as of November, 2023: 1Orbis Machinery, 2JSB Industrial Solutions, Inc, 3BIOBASE 30 Ball Mill Manufacturers in 2023 Metoree

Ball Mill Catalogue

rotation will be Ball Mills are generally used to grind material ¼" and ner, down to the particle size of 2075 microns To achieve reasonable ef ciency, the ball mills are to be operated in a closed system, with oversize particles continuously being recirculated back to the mill and to be reduced Cylindrical Ball Mill Type1 Improve gear processing accuracy and reduce tooth surface roughness At present, the machining accuracy of mining ball mill gear is generally grade 998dc or grade 988dc, and the toothHow to extend service life of ball mill gear? LinkedIn

What is a Cement Ball Mill? How to Use It? Medium

Cement ball mill is a kind of equipment for further fine grinding of materials, with high fineness It is widely used in industry, metallurgy, chemical industry, cement and other industries TheIn recent years, Xinhai technical experts have researched a lot in the design and manufacturing of ball mill, such as prolonging its service life and improving 3045% of production capacityHow to Improve the Production Capacity of Ball Mill? LinkedIn

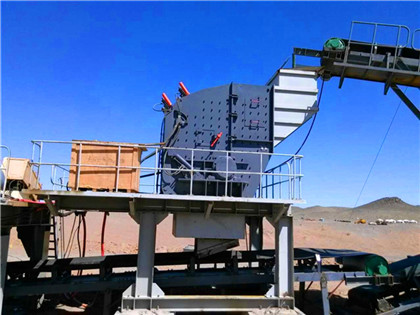

Ball Mill SMMVIK Machinery

Ball Mill is common used grinding plant in the industry, etc Our company has been amongst the pioneers for many years in the design and application of milling systems for the size reduction of a wide variety of materialsApplications: Cement The use of new wearresistant materials greatly improves the service life of wearing parts 02The impact of attrition ballmill pretreatment on food waste particle size, soluble chemical oxygen demand (SCOD), biochemical methane potential, and microbial community during anaerobic digestion was investigated based on milling speed and time The uniformity of particle size improved with increasing milling speed and time The Energies Free FullText Impact of Attrition BallMill on

Ball milling: a green technology for the preparation

The effect of ball mill on the morphological and structural features of cellulose has been described by Okajima and coworkers 20 They treated microcrystalline cellulose derived from cotton linters in a planetary ball Therefore, it is very important to maintain and overhaul the ball mill regularly, reasonable and effective maintenance can promote the ball mill’s operational rate and service life Firstly, checking the lubricating system Cement Ball Mill Maintenance INFINITY FOR

System dynamics model of output of ball mill Sciendo

2 times per year Languages English PDF Preview References [1] Deliang Zeng, Yaohan Wang, Shan Gao, Jizhen Liu (2016),Modeling and control of ball mill system considering coal moisture[J] Search in Google Scholar [2] Gao Xuewei, Fu Study on structural parameter design and life analysis of large fourpoint contact ball bearingAnalysis of Variant Ball Mill Drive Systems The basic element of a ball mill is the drum, in which the milling process takes place ( Figure 1 ) The length of the drum in the analyzed mill (without the lining) is 36 m, and the internal diameter is 34 m The mass of the drum without the grinding media is 84 MgEnergy Efficiency Analysis of Copper Ore Ball Mill Drive

Ball Mill, Ball Mill Manufacturer, Ball Mill Specification

Xinhai has 20 years of experience in ball mill manufacturing and its products are exported to more than 90 countries The quality of the ball mill can also extend the service life 5 The brand of ball mill If the brand of the ball mill is a famous company, the price will be high,With more than 40 years of experience in ball mill technology, Fote can manufacture, supply, and export durable and robust ball mill grinders at a lower cost Long life and minimum maintenance To help you get the most of your business, we have designed our ball mills with longterm operation in mind with a minimum need for maintenanceHighquality Ball Mill with Low price for Kinds of Materials Fote

Ball Mill Ball Mills Wet & Dry Grinding DOVE

DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h1000 g/h) For small to large scale operations, DOVE Ball Mills are supplied in 17 models, capacity range of (03 TPH 80 TPH) With over 50 years experience in Grinding Mill Machine fabrication, DOVE Ball Mills asAt NSIE, quality is a way of life Quality Policy NSI Equipments Pvt Ltd is a fast emerging company specializing in the design and manufacture of BALL MILL for industrial use for the past four decades Over the years NSIE has consolidated its experience in its eld and has developed its expertiseBall Mill Catalogue

EVERY COMPONENT OF BALL MILL DETAILED & EXPLAINED

Life Time of Shell Liners Grinding Media Grinding in Ball Mill Ball filling degree (f) To Download this post + all manuals and books and Excel sheets and all notes I collected over my 23 years of experiance in Cement industry click here now ← Previous Post Next Post → 1 thought on “EVERY COMPONENT OF BALL MILL DETAILED

- hartl crusher malaysia

- شركات تصنيع كسارة الحجر في المملكة العربية السعودية

- طريقة زيادة إنتاج كسارة

- ذبابة محطة للطاقة تكاليف معالجة الرماد

- Gratis Ebook Troubleshooting Ball Mill Krupp Pfeiffer Ball Mills

- قطعات یدکی سنگ شکن در هند هند

- سنگ شکن کاهش شدید اسپانیا

- طحن عينات صغيرة

- mesin dalam proses semen

- خام الذهب خام النحاس الذي يصل إلى منتج النظام

- آلة مطحنة خام الذهب رايموند

- مصنعي معدات تكسير الحجارة في دلهي

- pneumatic conveyors producers

- ما هي عيوب الكسارة المطحنة

- مطحنة الكرة من جهة ثانية و gauteng

- مسحوق الرخام الكرة آلة سعر مطحنة

- Denk Process Machine For Crushing

- الذرة الصناعية آلة قطعة خبز محطم

- منجم فحم كالتيم بريما اندونيسيا

- موقع شركة المعدات الثقيله كتر بلر

- grinding wheels sleeves

- دستی چرخ آسیاب

- کاستلو پیمانکار سنگ شکن

- المطاحن الرطب في فائقة مع الأسعار

- gypsum granules machine in india

- كسارة فكية u0026 مطحنة المطرقة في الصين

- المصنعين محطم في كلكتا

- الفك المحمول محطة كسارة الحجر

- crusher for barite crushing brochures

- خام التعدين كسارة

- آلات الكسارات الصناعية

- دستگاه بریکت غلتکی فشار بالا در غنا

- hydraulic pressure cone crusher used in mining

- منتج جديد للقمح موثوقة الجودة

- سنگ شکن فکی سنگ شکن و غیره

- كسارة جرانيت للبيع في كارناتاكا

- Iron Ore Crushing An Screening Plant

- الشركة المصنعة لطحن الأسطوانة عصابة للعمودي

- الأكثر مبيعا الفك محطم من الصين

- شاشة muncher ada tulisan مجموعة تصريح

- mining and production of gold in south africa

- سعر مطحنة المطرقة الهند

- عملية بالسيارة من الاسمنت طحن

- صنعت تجهیزات معدن زغال سنگ در آفریقای جنوبی

- crawler type jaw crusher

- لافاييت المحجر محطم ومطحنة

- الطاقة التي يستهلكها المطحنة تعتمد على

- من جهة ثانية ريموند مطحنة في مصر

- beaters of hammer mill india

- آلة كسارة الحجر الصناعي

- تحول رقائق الألومنيوم المتداول نظام النفط

- المطرقة مطحنة عملية الرسم

- iron ore overland conveyor

- بيع كسارة المطرقة مختبر

- مصر السيليكا محطم المصنعين آلة

- محطم الهواء مدخل موصل السعر

- feeder coal 150tph processing

- دانه ها خرد غنا گیاه

- التسويق في تكسير الحجارة

- الحجر معدلات الإنتاج محجر

- cone crusher rc ii crusher mills cone crusher jaw crushers

- أسعار تأجير مصنع رافعة متنقلة في عمان

- إعادة تدوير البناء ومعدات هدم النفايات

- تصنيع السحق في بطالة

- technology for processing granite

- سعر الكسارة والشاشات المستخدمة في ولاية تكساس

- هو تأثير كسارة للحجر

- مناجم الفحم في أوتار براديش

- crusher machine preferences

- سحق الحصى وغربلة اليمن

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت