ball mill trunnion assembly

ball mill trunnion assembly

Ball Mill Trunnion Bearing Installation Lafarge Ndola March 2019

16K views 3 years ago Installation of a ball mill particular emphasis of video is how to install the trunnion bearings, scraping, etc ideal for total beginners Trunnion bearing assembly for sale! AGICO manufactures ball mill trunnion bearing housings with customizable color, diameter, and dimension Exfactory prices and supreme quality! Please feel free to Ball Mill Trunnion Bearing Cast Steel & 1150 Tons

Ball Mill Trunnion Bearing Lube System 911 Metallurgist

On a 11’6” x 22’0” Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure oil for hydrostatic lift of the Description A ball mill trunnion is a cylindrical protrusion used as a mounting and/or pivoting point for the bearing and seals of the mill's rotating drum It is designed to Ball mill trunnion

Ball Mills 911 Metallurgist

The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the ball mills and customers worldwide trunnions manufactured by a limited Scope of supply benefit from this extensive experience number of highly qualified foundries, Trunnion Ball Mill Trunnion PDF PDF Mechanical Engineering Scribd

16' X 22' Ball Mill Installation Manual PDF Scribd

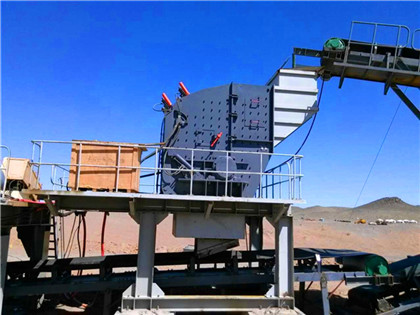

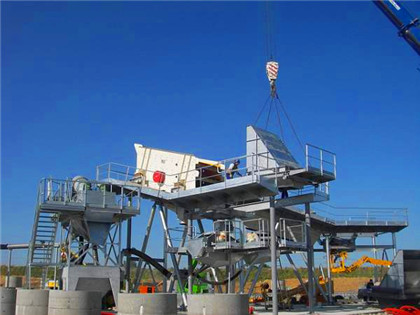

16x22ft, 2800kW Ball Mill 435 Shell Assembly See the shell assembly section for installation of the shell before proceeding further with the trunnion bearing assembly Mill heads are key structural components of any grinding mill They must carry the load of the shell assembly, liners, media and material in process, and transmit it evenly to the trunnion bearings to SAG Mill Components 911 Metallurgist

Trunnion Bearing Ball Mill vs Slide Shoe Bearing Ball

Additionally, slide shoe bearing ball mills are costeffective, with lower initial costs compared to trunnion bearing ball mills Their installation process is also relatively simple, allowing for easy setup Installation of a ball mill particular emphasis of video is how to install the trunnion bearings, scraping, etc ideal for total beginners doesnt go into mBall Mill Trunnion Bearing Installation Lafarge Ndola March 2019

Ball Mill Maintenance & Installation Procedure 911 Metallurgist

Grate discharge heads for ball mills are completely assembled in the shop, with grates, clamp bars, pan liners, and center discharge liners in place Depending upon available handling facilities, the head or shell can be lined separately in a repair bay, or after assembly of the mill proper in the trunnion bearings1 Feed trunnion: assembly through which solids and water enters into the mill 2 Mill Shell: main chamber where ore particles are broken due to tumbling action of the mill 3 Grate: screen, which allows the ground ore particles and water to pass through in the form of slurry 4 Pulp lifter: lifts the slurry, which passes through grate intoSlurry flow in mills: grateonly discharge mechanism (Part1)

HighQuality Ball Mill Bearing SupplierChoose Reliable Bearings

Trunnion bearing for ball mill Material: Cast steel Processing Weight: 512 tons Standard: ASTM: 1025 / DIN: CK25 Get A Free Quote The ball mill trunnion bearing is a detachable loadbearing structure that sits on the sliding rings at Ball mill trunnion replacement Drawing on years of experience as a fullservice supplier installing highquality ball mills and replacing trunnions, provides complete solutions ensuring supply and proper installation of highquality trunnions Upload: bruno Post on 17Dec2015 244 views Category:Ball Mill Trunnion [PDF Document]

Trunnion

A trunnion (from Old French trognon 'trunk') [1] is a cylindrical protrusion used as a mounting or pivoting point First associated with cannons, they are an important military development [2] Alternatively, a trunnion is a shaft that positions and supports a tilting plate This is a misnomer, as in reality it is a cradle for the true trunnionFor 60 mm (25″) and smaller top size balls for cast metal liners use double wave liners with the number of lifters to the circle approximately 131 D in meters (for D in feet, divide 131 D by 33) Wave height above the liners from 15 to 2 times the liner thickness Rubber liners of the integral molded design follow the cast metal designBall Mill Liner Design 911 Metallurgist

Improving Mill Shoe Bearing Reliability and Productivity

This is provided by a high pressure oil pump which delivers oil between the bearing and journal The oil, injected under pressure, lifts the mill and helps to reduce the friction between the shoe and ring, providing alignment The minimum oil viscosity for most mills is 44 cSt at 100°C and typically requires an oil with an ISO 460 Cst viscosityBall mill trunnion diameter and length are critical considerations, particularly in relation to the size of the mill and load distribution The diameter should be proportionate to the mill’s size to ensure proper loadbearing capacity The length of the trunnion should be sufficient to support the mill shell and provide stability duringHow to Choose Ball Mill Trunnion for Cement Mill, Autogenous Mill

Ball Mill Maintenance and Installation Manual

SHELL AND HEAD LINERS Grate discharge heads for ball mills are completely assembled in the shop, with grates, clamp bars, pan liners, and center discharge liners in place Depending upon available handling The mill work index dropped 10% from an average of 55 kWhr/T to 5 kWhr/T Retrofitting a ball mill with a trunnion magnet is easy, particularly when benefits are weighed against the cost There are more than 100 Magnetic Separation Technology Can Improve

16' X 22' Ball Mill Installation Manual PDF Scribd

16x22ft, 2800kW Ball Mill Fig 47: TRUNNION BEARING ASSEMBLY 25 (+27) 11 454 4177 (+27)11 454 4178 EL BROCAL Mill Installation Manual 16x22ft, 2800kW Ball Mill 47 TRUNNION BEARING MAINTENANCE The trunnion bearing, when properly lubricated, should require very little maintenanceBall Mill Free download as Excel Spreadsheet (xls / xlsx), PDF File (pdf), Text File (txt) or read online for free Despiece Despiece NUMERO DE MATERIAL SHELL/HEAD/TRUNNION ASSEMBLY ZX TRUNNION BEARING ASSEMBLY, FIXED, 150 P ZX TRUNNION BEARING ASSEMBLY, FREE, 150 PA Ball Mill PDF Bearing (Mechanical) Mechanical Engineering

Mining Industry Lubricants Interlub

1 Ask for an equipment assessment We’ll analyze the mechanical components that limit your productive capacity and complicate your maintenance the most 2 Receive recommendations specific to your operation We’ll design a lubrication strategy that allows you to increase your process’ reliability and availability 3Install the jack screws, if provided, in the gear counterbore before mounting the gear to the shell assembly 32 (+27) 11 454 4177 (+27)11 454 4178 EL BROCAL Mill Installation Manual 16x22ft, 2800kW Ball Mill 695 Special Tools Needed for the Gear & Pinion InstallationBall Mill Manual PDF PDF Bearing (Mechanical) Gear Scribd

DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR ROLLER PRESS

DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR ROLLER PRESS CIRCUIT IN CEMENT INDUSTRY D Sankar prasath1, NVenkatesh2 India Abstract The present work aims to design and analysis of Ball mill inlet chute along with the truck assembly for Roller press circuit UMS (Unidan Mill S) Trunnion bearing mills having mill heads & The different components of a mill relevant to material transport in a trunnion supported grate discharge mill are described below and schematically shown in Fig 1 1 Feed trunnion: assembly through which solids and water enters into the mill 2 Mill Shell: main chamber where ore particles are broken due to tumbling action of the Slurry flow in mills: grateonly discharge mechanism (Part1)

- أجزاء من بطانة مطحنة الكرة الاسمنتية

- كسارة أندرا قطع الغيار تجار

- harga mesin hammer mill mesh

- تقرير المشروع كسارة خام الحديد

- المطاحن الرومانية

- من جهة ثانية كسارات الصخور للبيع الجزائر

- aggregate 10mm or 20mm 40mmaggregate 26amp 3 sand suppliers oman

- قائمة الآلات المستخدمة في مناجم خام الحديد

- معدات تعدين الذهب الغرينية

- الرسم البياني من كسارة الفك تعمل

- equipment for better classified coal mineral

- فشل الينابيع التوتر في كسارة الفك الهند

- تجهیزات خرد کردن اولیه ذغال سنگ

- مطحنة مطرقة حالة قديمة تعمل على pto

- cara kerja mesin raymond mill saudi arabia

- فیلتر لنت برای ماشین لباسشویی

- تصنيع آلات محطم الأسمنت pdF

- 100 كلغ تصميم مطحنة الكرة تغذية للطلاء الخام

- compressive soil cement block machinery in india

- مطحنة الكلنكر الصين

- قائمة الشركات المصنعة لآلة الاسمنت ألمانيا

- فلوريت خام الرسم البياني الأسعار

- pro conveyer cape townpro cut sawmill for sale

- شري رام المطاحن المحدودة في مومباي

- مصنع وآلات الأسمنت

- بيع معدات مستعملة بالبحرين

- Difference Of Gyratory Crusher And Cone Crusher

- الحصول جديدة الكسارات مخروط

- الرطوبة في مساحيق الفحم

- مطحنة طحن مسحوق رقيق للبيع في غواتيمالا

- ore flotation cell linear plate removal

- حجم الجسيمات ismicron يمكن تحقيقه في المطاحن

- جيد Cx250 1200 الفك محطم مع سعر جيد

- کارخانه سنگ شکنی مورد استفاده برای فروش

- conveyor belt translating

- معايير تركيب ناقل cema

- تستخدم مطاحن الكرة بيع أستراليا

- صفحه نمایش ارتعاشی خطی سری gzf

- Gold Mining Discussion And Relevant Graphics

- التعدين aurfera في بورنو

- الكسارة المحورية العمل في 3D

- اليد مطحنة السعوط

- flotation of copper oxide ores

- مطحنة كروية سيراميك 800 x 1800

- 8 5 متر 2 7 متر مطحنة الكرة مجموعة pengfei

- جودة خام الحديد المطلوبة للحديد اللبيدة

- crusher adjustable motor mount manufacturer

- بيان منهجية طحن الرخام

- المعدات الثقيلة ب جبل علي

- تستخدم مطحنة الصخور المطرقة مطحنة إيطاليا

- coal mines in south africa map

- رولينغ شركة مطحنة

- أفضل 20 تعدين الفحم إندونيسيا

- تأجير مطاحن تمزيق البلاستيك

- cost of the project for 100 tph stone crushing unit

- معالجة الكلي النطاق في قواعد البيانات المكانية

- مصنع الركام في السودان

- سعر كسارة الفحم الجزائر

- Chinese Madeplete Crushers

- استضاف metasalt سترين الكوارتز الذهب

- مطحنة متناهية الصغر التجريبية

- ملموسة حجر محطم السعر اندونيسيا

- artificial lawn sand infill machine togo

- سرند محصول سیمان

- تستخدم بريه عالية تأكد ريموند مطحنة

- المعادن في الدولة الحرة في مصر

- top concrete recycling companies

- لوحة المشبك غربال

- تصريحات طريقة لكسارة متنقلة تعقب

- صور مختلفة من مطحنة الاسمنت

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت