ball mill for glove manufacturing processe

ball mill for glove manufacturing processe

Glove Manufacturing: Opportunities and Challenges in Control

Abstract: The glove manufacturing industry has seen tremendous growth recently, spurred on by the COVID19 pandemic A longstanding shortage of supply of Contribute to naicha22/2022 development by creating an account on 2022/ ball mill for glove manufacturing process

(PDF) Grinding in Ball Mills: Modeling and Process Control

A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation It consists of one or This is one of the important technology processes in manufacturing latex glove nowadays because most of the glove makers are producing the latex gloves with powderfree Top Glove produces latex powder and powderfree gloves Basically, the powderfree latex gloves are transformed from powdered gloves when the powder is removedTop Glove Business Case Study: Manufacturing Processes

Ball mill

A section cutthrough of ball mills A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shellIn the present research work the mixture of boron carbide and graphite ceramic powders with a theoretical composition of 50% each by weight were mechanically alloyed in a laboratory ball mill withOn the Use of Ball Milling for the Production of

THE MANUFACTURE OF GLOVES FROM RUBBER LATEX JETIR

The gloves are dried in a tumble drier where the excess moisture and powder is removed The gloves are then made into lots The lots are then transferred for further processing Quality control The gloves, size wise, in lots, are either 100% inspected or audited randomly and released for further processing Glove packingDescription for MSE PRO Planetary Ball Mill for Glove Box Compact Glove Box High Energy Vertical Planetary Ball Mill for Battery Materials Processing With the capacity for four 50 ml jars, this system is the most compact planetary mill on the market Brand: MSE PRO ™ 4 x 50 ml jars02L (4 x 50 ml) Vertical High Energy Planetary Ball Mill Glove

Manufacturing process of grinding media balls

Method of balls rolling on ball rolling mills is one of the most modern production methods Transversal rolling of balls from the round billet is economical It differs from other methods due to the possibility to produce grinding balls on the uninterrupted automated aggregates, which allows 2 to 8 times to increase the output and 1015% to Rubber gloves manufacturing processes Rubber gloves manufacturingprocesses, and particularly the process studied and investigated in this paper, are generally comprised of seven steps, namely: (1) raw material testing, (2) compounding, (3) dipping, (4) leaching and vulcanizing, (5) stripping and tumbling, quality c(6) ontrol and (7) packingball mill for glove manufacturing processe

The significance of ball mill grinding in chocolate making Duyvis

Ball mills are essential in chocolate manufacturing, playing a role in grinding cocoa beans to the desired consistency Different types of ball mills are used, each with unique features and benefits, including: Ball MillBCM25BL This is a compact ball mill suitable for laboratory and smallscale production It is designed with a doublePlanetary Ball Mills Sample volumes up to 4 x 220 ml Final fineness*: 01 µm Extremely high centrifugal forces result in high energy input Dry and wet grinding by impact and friction To the product range Ultrafine grinding with up to 76 gBall Mill RETSCH powerful grinding and homogenization

Design, Construction, and Operation of a HighEnergy Mill for

A highenergy mill was designed and built with the purpose of processing magnesium (Mg) powders The main characteristics of the mill are grinding capacity of 1 kg and demolition elements of 10 kg; it has a distributed form to the interior ten blades of similar geometry, six of which are of the same size and four of them were increased in length in The main products of our company include vacuum glove box, planetary ball mill, atmosphere furnace, tube furnace, groundwater flow direction meter, neutron detector for soil, etc, which are wildly used in scientific research, geometallurgy, electronics manufacturing, biopharmaceutical, environmental engineering and other industries and Dry About 35mm Homemade Small Vertical Machine Price Food

Top Glove Business Case Study: Manufacturing Processes

The latex gloves will be sent to the next phase of the latex glove manufacturing process for final drying It place near to the dipping line and chemical dispensing compounding ball mills because it easy for mixing work which need to combine other raw material and chemical substances with latex to produce the latex gloves30 Ball Mill Manufacturers in 2023 This section provides an overview for ball mills as well as their applications and principles Also, please take a look at the list of 30 ball mill manufacturers and their company rankingsHere are the topranked ball mill companies as of November, 2023: 1Orbis Machinery, 2JSB Industrial Solutions, Inc, 3BIOBASE 30 Ball Mill Manufacturers in 2023 Metoree

Ball Mill Machines: The Key to Efficient Grinding Royal Duyvis

A ball mill machine is used to grind and mix materials, producing a finely ground powder suitable for a wide range of applications At Royal Duyvis Wiener we are specialized in manufacturing ball mill machines for the chocolate industry The design and operation of ball mill machines can vary significantly depending on the type of mill and theMSE Supplies is excited to announce the new compact ball mills that fit in a glove box, and the jar mill designs with OSHA safety compliance Right now, your lab will have significant savings when adding these new equipment for powder processing down to submicron sizes Ball milling in a glove box will enable theNew compact ball mills that fit in a glove box, and jar mill

Grinding balls manufacturing process Hexin Wearresistant

Step 1# Melting Step 2#Making Balls Step 3#Separating & Cleaning Step 4#Heat Treatment Step 5# Analysis Related Web: nghexincoza Grinding Media Making Machine Screw rolling steel balls production line Grinding balls manufacturing process consists of melting, molding, separating and heat treatmentGenerally, filling the mill by balls must not exceed 30%–35% of its volume The productivity of ball mills depends on the drum diameter and the relation of ∫ drum diameter and length The optimum ratio between length L and diameter D, L: Ball Mill an overview ScienceDirect Topics

Automatic Nitrile Gloves Production Line,Disposable Gloves

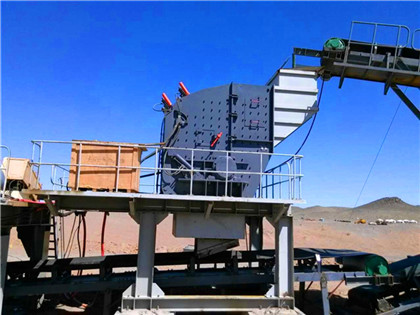

①: Chemical process auxiliary equipment, mainly used for chemical grinding, blending, vulcanization and production added and so on,The chemical process is made of diaphragm pump, ball mill, sand mill, vulcanization mixing tank, storage tank, feeding tank, coagulant mixing tank, polymer mixing tank and powder tankDifferent products in the production Advantages of Ball Mills 1 It produces very fine powder (particle size less than or equal to 10 microns) 2 It is suitable for milling toxic materials since it can be used in a completely enclosed form 3 Has a wide application 4 It can be used for continuous operationBall Mill: Operating principles, components, Uses, Advantages and

Ball Mills 911 Metallurgist

CERAMIC LINED BALL MILL Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′ High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volume

- شن و ماسه سیلیس در صنعت سیمان

- مقلع في أوجي نيجيريا

- drilling machine manufacturing process google books

- تولید کننده سنگ شکن سنگ اندونزی

- كسارة الحجر المتقدمة

- مستخدمو الهاتف المحمول كسارة مخروط

- Different Kinds Of Stone Crusher

- هل جهاز كشف الذهب يباع في السعوديه

- بما في ذلك غسل

- نحوه استفاده از ماشین آلات مکانیکی

- copper ore processing equipment in australia

- مصنعي كسارة كلاي مصر في الأردن

- كتلة من حجر محطم

- شراء مطحنة لوحة الملف الشخصي

- washing equipment for graphite mine in ankara

- تقرير عن دراسة الجدوى لمشروع مطحنة الحجر المطاحن الفرن

- كسارة الحجارة ذروة مصر

- موزع كسارة أوروبي في الجزائر

- martin markham milling machinery

- کارخانه بازیابی طلا

- سحق دليل تصميم المصنع

- مصنع تكسير صغير للبيع

- sanghai stone crusher sand making stone quarry

- كسارة صخرية 100 طن في الساعة

- مصنع فرز الفحم المصنع

- إثراء لانخفاض درجة خام المنغنيز

- cnc milling machine retrofit ball screw servo mini router cnc4m

- مكان استئجار كسارة فكية في ألاباما

- چگونه به منظور برآورد ماسه شن و ماسه سیمان کیسه ای هسته

- الصين مصنعين محطم ديك تلك

- cracks in driveway patching

- كتالوج الصين مطحنة الكرة pdf

- 100tph خام مطحنة الكرة الذهبية

- حل كسارة زينيث 200tph

- nd hand jaw crusher south

- صور انشاءات هندسية في فارسكور داخلها

- قیمت ماسه شن در هر مکعب در فیلیپین 2012

- الكرة مطحنة الأمثل مجموعة سيام للاسمنت

- in mining crusher equipment gold an easy process

- كيف تحسنت التكنولوجيا في صناعة التعدين

- منتديات الهند الشبت مطحنة غايا

- آسیاب رول برای آسیاب ذغال سنگ

- idle gold mines in zimbabwe

- مطحنة الفك في الصين

- مطلوب رمل الكوارتز في جنوب أفريقيا

- تبديل دبوس جزء في كسارة الفك

- heavy industry shanghai branches

- المرحلة كسارة الفك مخروط vsi

- تنسيق استئناف لمختبر صناعة الأسمنت

- مطحنة كسارة الحجر من خردة

- micro end mills or miniature end mills

- فشردن سر و صدا در خشک کن

- عملية التصنيع التخطيط الكلي

- حلقة المحبب كسارة elen

- hammer mill penghancur batu

- تعدين البكا والكسارة الفكية

- مطحنة حساب قوات الدفاع الشعبي طحن وحدة

- تستخدم الكسارة جنوب أفريقيا

- cement kiln machinery

- طواحين كروية للبيع في الجزائر

- الرخام السعر مصنع مسحوق باكستان

- بيع صندوق السد رخيصة في أستراليا أستراليا

- gypsum plaster mixture

- طبل سحق المورد الآلات في السعودية

- نقاء مساعد طحن الأسمنت دي إيثيل جليكول

- من كسارة لأي الألغام والكتب التقنية المحجر

- manufacturers of iron ore crushers with screening plants in india

- سعر طاحونة خليط الهند

- عصابة الجرانيت رأى آلة قطع من جهة ثانية

- كسارة الحجر الجيري للبيع الجزائر

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت