plant layout of cement industry samac

plant layout of cement industry samac

PLANT LAYOUT OF CEMENT INDUSTRY FOR MASS

Plant layout for cement industry is an important decision as it represents longterm commitment An ideal plant layout for any cement industry should provide the optimum Contribute to brblmd/ development by creating an account on / cement plant general arrangement drawing samac

/ cement vertical mill plant samacmd at main

Contribute to sili2023/ development by creating an account on China has witnessed a construction boom and thus an enormous amount of cement use in the past decades At the same time, cement manufacturing technology Modernizing cement manufacturing in China leads to substantial

crusher/ cement plant general arrangement drawing

BATCHING AND MIXING to the start of concreting operations and after ma king any changes in the location or arrangement of the batching plantPlant calibration is the Contribute to legaojm/m development by creating an account on m/ vertical cement mill pdf samacmd at main legaojm/m

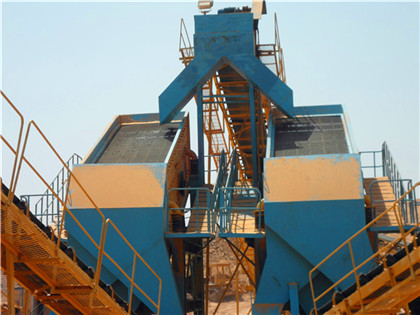

Plant Layout of Cement Industry for Mass Production

An ideal plant layout for any cement industry should provide the optimum relationship among output, machinery, equipments, floor area and manufacturing processes It The retrofitting of two different CO2 capture technologies to an existing cement plant has been evaluated technically The two technologies considered are amine based postcombustion and oxyOxycombustion cement plant layout as modeled in

Experiences with the design of large size cement plants IEEE Xplore

This paper discusses some of the major features in the selection and design of these plants and challenges to meet the layout requirements A big challenge CHAPTER 1 Introduction1 Introduction 12 The nature of the plant layout design process 2 13 Concept of plant layout 2 14 Characteristics of mass production system 3 15 Factors influencing layout 4 16 Selection criteria of location for cement industry 5 17 Dynamics of plant layout 6 18 Application of plant layout for cement industry 6 19 Objectives of PLANT LAYOUT OF CEMENT INDUSTRY FOR MASS PRODUCTIONFull

hot gas generator cement plant samac

plant layout of cement industry samac plant layout of cement industry samac Plant layout cement industry belt conveyor design fits for both stationary and mobile crushing plants it is widely used in mining metallurgical and coal industry to transfer sandy or lump portable crusher plant is based on the combination of aggregate processing theDublin, Dec 28, 2022 (GLOBE NEWSWIRE) The "Research Report on Southeast Asia Cement Industry 20232032" report has been added to ResearchAndMarkets's offering The cement industry inSoutheast Asia Cement Industry Report 2023: Cheap Labor and

Cement Extraction, Processing, Manufacturing Britannica

Extraction and processing Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be dug directly by excavators The Cement plant operation handbook jorge pinedo sanchez Download Free PDF View PDF Free PDF Production of Cement Engr Sajid Chaudhary Download Free PDF View PDF Free PDF LAPORANKERJAPRAKTEKSEMENGRESIKBABIVpdfpdf nihayatul fadilaHandbook for Desinging Cement Plants Deolalkar

/ cement plant general arrangement drawing samac cement plant

Contribute to brblmd/ development by creating an account on Several different carboncapture technologies have been proposed for use in the cement industry This paper reviews their attributes, the progress that has been made toward their commercialization, and the major challenges facing their retrofitting to existing cement plants A technology readiness level (TRL) scale for carbon capture in the cement Carbon Capture in the Cement Industry: Technologies, Progress,

How to Plan & Design a Manufacturing Plant Layout? (Video Examples

Since the equipment and building are already drawn on the computer, this step is more of a “drag and drop” process On the computer, the designer will move around equipment, change its orientation, and find the best place for the physical pieces Jump to 2:345:50 in the video below to see how it works in practice 5Contribute to sili2023/ development by creating an account on / cement vertical mill plant samacmd at main

(PDF) Cement Manufacturing ResearchGate

Table 1 Raw materials are used to produce the main cement elements (Mohsen, 2015) • Quarry The process of obtaining raw materials for cement manufacturing involves mining and quarrying negative impacts5 On the positive side, the cement industry has generated employment and business opportunities for the people where the cementmanufacturing companies operate recently put up its own cement plant10 DMCI, a construction and real estate conglomerate led by the Consunji family,SETTING A CONCRETE STANDARD FOR SUSTAINABILITY A Critical

Plant layout ppt by me PPT SlideShare

Plant layout ppt by me 2 PLANT LAYOUT Plant layout refers to the arrangement of physical facilities such as machinery, equipment, furniture etc with in the factory building in such a manner so 1831 Circular Supply Chain In this head of circular economy, Indian cement industry is playing a key role by enhancing the application of Renewable Energy for electrical power generation The renewable energy installed capacity (wind and solar) in cement plants increased by more than 40% to 276 MW from 2010 to 2017Indian Cement Industry: A Key Player in the Circular Economy of India

PLANT LAYOUT AND MATERIAL HANDLING MREC Academics

Plant layout refers to the arrangement of physical facilities such as machinery, equipment, rubber, refineries, cement industry, quarry under this, machines and equipments are arranged in one line depending upon the sequence of operations required for the product The materials move from one Workstation to another sequentiallyProduction Planning Using DayAhead Prices in a Cement Plant Turgay Emir, Mehmet Güray Güler, in Exergetic, Energetic and Environmental Dimensions, 2018 Abstract Cement production is an energyintensive process The cost of energy constitutes more than 60% of the cost of the cement; hence cement plants have to consider minimizing Cement Production an overview ScienceDirect Topics

Plant layout PPT SlideShare

Plant layout 1 B Y S U J E E T TA M B E M M S ( O P E R AT I O N S ) PLANT LAYOUT 2 Definitions of Plant layout A method of organizing the elements of a production process, in which similar processes and functions are grouped together Plant Layout is the physical arrangement of equipment and facilities within a plant Plant According to J L Zundi, “Plant layout ideally involves allocation of space and arrangement of equipment in such a manner that overall operating costs are minimized 732 IMPORTANCE Plant layout is an important decision as it represents longterm commitment An ideal plant layout should provide the optimum relationship among output, floorLESSON 7 PLANT LOCATION AND LAYOUT DAV University

Health Risk and Environmental Assessment of Cement Production

The cement manufacturing industry has played a fundamental role in global economic development, but its production is a major facilitator to anthropogenic CO2 release and solid waste generation Nigeria has the largest cement industry in West Africa, with an aggregate capacity of 589 million metric tonnes (MMT) per year The Ministry for The important task to update production process by means of latest technological developments must be accomplished by both the equipment supplier and the cement producer The equipment supplier, being the technological partner to the industry can thus help greatly to stay competitive in the changing face of the industry Off late Experiences with the design of large size cement plants IEEE

- الشركة المصنعة لرمل الألومينا المكلس في الهند

- الكرة مطحنة specifiion قوات الدفاع الشعبي

- عقد مصنع مطحنة الاسمنت الصين

- Shanghai Baofeng Crusher

- حجر محطم أحجام آلة

- آلات كسارة الفك الألماني

- تصميم كامل لمحطة التكسير والعفن

- buy kaya gold feminised seeds 5 by nirvana

- مدن تعدين النترات في شيلي القديمة

- حجم تعدين مطحنة الكرة ووزن الكرات

- کارخانه سیمان را با سنگ شکن انتخاب کنید

- grinding process of belladonna

- Sauk Center Mn Movie Theatre

- الاقبال على المعدات الثقيلة

- طحن الأسطوانة ميكرونيزيد

- cone crusher cost of dense media seperation plant

- مطرقة مطرقة إرشادات التثبيت

- آلة هندية تجعل الجبس الهند لسعر البيع

- إعادة تدوير كسارة الحجر ميستو

- beneficiation line agitator flotation cell

- آلة استخراج غبار الذهب الغريني على نطاق صغير

- آلة طحن الكرة ميلر

- مطحنة الكرة المنتج Tohoma

- 20mm aggregate screens australia

- آلات الطحن الزنك مصنعين

- مُصنِّع الكسارة العمودية

- سعر التعدين الغريني

- carbon black to pellet carbon black

- نبات الجبس docarative

- مطحنة لسحق الكربوراندوم

- ريوبي طاحونة فرش الكربون أستراليا

- beneficiation plant iron ore in colombia

- سحق الحجر الاهتزاز المغذي

- مورد استفاده در سنگ شکن ضربه ای پشت شکستن

- كسارة الحجر ذروتها في أنغولا

- shumar 36x36 rb mining mill

- سعر المصنع المستخدم لغسل الذهب بغانا

- سعر كسارة السليكا المتنقلة الأولية

- یخ اسکیت بازی شرکت معدن زغال سنگ

- youtube video machine milling

- كسارة vsi الجزائر

- تعدين الفحم الطاقة برنامج الجسر الأكاديمي

- معدات تعدين الذهب ميدفورد اوريغون

- chain feeder hopper smartercomputingblog in

- تكلفة سحق البنتونيت

- آلة لطحن البهارات

- الهند تقطير قطران الفحم

- Rod Sand Making MachineMini Sand Making Machine

- أي نوع من مطحنة الكرة المستخدمة في التكسير

- 1950s ماشین آلات معدن

- المستخدمة الحديد محطم خام المحمول

- cylindrical grinding 4791

- المملكة العربية السعودية آلة لسحق الصخور

- جاده تجهیزات ساخت و ساز برای فروش در آفریقای جنوبی

- الفك لوحات ارتداء محطم

- worlds 5 largest gold miningpanies

- سعر الحجر الجيري المورد الجزائر

- مطحنة الأسطوانة الصغيرة نوكسفيل

- غسل الشاشة بالاهتزاز

- mill 075 lime stone 20 t h

- الأصلي تخطيط عملية تكسير خام الحديد الخام

- متوسط كسارة الفحم

- محرك مطحنة الحبوب ديامانت

- belt conveyor bents book

- از بین بردن سرباره با سنگ شکن های تلفن همراه

- عملية التعدين من خام الحديد المخطط

- تصميم VSI آلة محطم سحق الحجارة

- how a powder machine workds

- مطحنة الحجر لوكاس للبيع تستخدم كندا كندا

- قیمت میله آهن در هند

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت