gyratory crushers worldgyratory crushers sm

gyratory crushers worldgyratory crushers sm

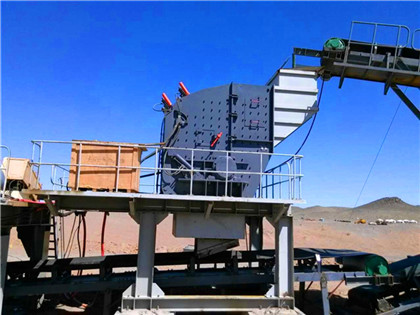

Gyratory Crusher Pro

Key Benefits Highest capacity available in market Extralarge feed opening available Significant energysaving effect CAPEX advantages through weight optimised design TON CG800i crushers offer excellent reliability and safer & faster maintenance up to 30% faster than competing crushers A robustly designed onepiece main shaft and CG800i Gyratory Crushers SRP

Gyratory Crusher an overview ScienceDirect Topics

Gyratory crushers work on the same principle as cone crushers (Figure 44(c)) These have a gyratory motion driven by an eccentric wheel These machines will not accept Gyratory Crushers TC, NT and TS model crushers Open the catalog to page 1 Our experience with Mining Industries (Minerals, Cement, and Aggregate) has resulted in a complete line of Gyratory Crushers to Gyratory Crushers DorrOliver Eimco PDF

Semimobile primary gyratory (SMPG) TON

The MKIII primary gyratory crusher can deliver up to a 30% capacity increase and reduce downtime by up to 70% The SmartStation provides optimal operation By combining Press release 3 January 2023, Copenhagen, Denmark has been chosen to supply the world’s highest capacity inpit crushing system to a leading copper miner in to deliver the world’s largest gyratory crusher

Gyratory crusher upgrades TON

Primary gyratory crushers are the initial driving force for the mineral processing circuit Adding extra production capacity can have significant effects downstream TON has introduced advancements that bring Gyratory crushers are the most common machine used in the primary crushing in the copper mining industry of Chile and worldwide, and they are designed for Torque Analysis of a Gyratory Crusher with the Discrete Element

Basics of gyratory crushers Latest News At IMS Enginnering

Basics of gyratory crushers Gyratory crushers are the initial driving force for the entire mineral processing circuitGyratory crushers comprise a spider, main frames, a main shaft, eccentric, main drive motor, and hydraulic cylinderThe motordriven horizontal shaft, a horizontal shaft driven by the eccentric rotation of the gear, and then Our Gyratory Crusher Pro offers our customers highperformance crushing operations under toughest conditions from 40°C to 50°C whether it is the heat of the Australian summer or the cold of the Norwegian winter Built for ultimate performance and easy maintenance, this hard rock crusher excels at the crushing of medium hard to hard rock Gyratory Crusher Pro

Crushing 101 Different types of crushers for

Jaw crushers can be divided into two basic types, single and double toggle In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation, along with the toggle plate, causes The gyratory crusher has no rival in large plants with capacities starting from 1200 t/h and above To have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must be much taller and heavier Also, primary gyratories require quite a massive foundation Primary crushing with impact crushersCrushers All crusher types for your reduction needs TON

Crusher an overview ScienceDirect Topics

Mechanical Crushing and Grinding Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Crushers Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer While gyratory crushers and cone crushers share similar basic principles, they are distinct in their applications, efficiency, and maintenance requirements The selection between gyratory crushers and cone crushers often comes down to the project’s specific needs, the type and size of the material being processed, and the required capacityGyratory Crushers vs Cone Crushers: What Are the Main

tackles the need for higher power, throughputs with

The unique topservice design prioritises safety, maintenance and efficient crushing performance, says Unlike other gyratory crushers that require workers to get in underneath the crusher to perform highrisk maintenance, the TS range allows service and maintenance to be carried out from above, increasing speed, safety and Finally, based on the iron ore coarsely crushed by the gyratory crusher, the dynamic characteristics of the C900 cone crusher were simulated by using the discrete element method (DEM), and theSimulation and optimization of gyratory crusher performance

to deliver the world’s largest gyratory crusher

has been chosen to supply the world’s highest capacity inpit crushing system to a leading copper miner in South America to boost its efficiency The order is valued at approximatelyPrimary gyratory crusher spare parts TON is the industry leader in manufacturing gyratory crushers with over sixty years of experience As the popular crushers, our primary gyratory crusher spare parts are continually improved with upgrades and developments When your production or environmental requirements are changing, Primary gyratory crusher parts TON

thyssenkrupp extends gyratory crusher winning streak

These proven design characteristics, combined with a growing track record in the Australian marketplace, have the thyssenkrupp jaw gyratory crusher ready for another exciting year in 2020 ThisTo study and optimize the gyratory crusher performance, taking the process of crushing iron ore by the gyratory crusher as the specific analysis object in this paper First, the discrete element method (DEM) analysis model of the iron ore based on the bondedparticle model (BPM) is established On this basis, the impacts of the mantle Simulation and optimization of gyratory crusher performance

Stone Crushers: A Technical Review on Significant Part of

Primary crushers are heavy duty rugged machines used for crushing RunofMines ore (–) 15 m and convert them into stones of size 100–200 mm in dimension to make them suitable for further crushing process Most commonly used primary crushers are gyratory and jaw typesThese gyratory crushers have been operating successfully in some of the worlds harshest conditions for 50+ years This ongoing improvement has taken us from the original Bulldog Crushers through the world renowned TC model Crushers, to the NT line with updated maintenancefriendly features, and now into our current TopServiceFLS GyratoryCrusher Brochure 2015 PDF Scribd

Primary Gyratory Crusher High Performance GY Series

gyratory crushers are offered with either smooth or grooved mantles Grooves are usually used for the processing of harder materials Proven success around the world! USA 109 Development Drive Mt Braddock, PA 15465 PO Box 1064 Uniontown, PA 15401 info@hazemag nahazemag 724 439 3512 724 439 Recognized as the world leader, TON Outotec Mining and Construction Technology offers the complete range of primary gyratory crushers to meet all application requirement Machine size* Feed opening mm (in) Mantle diameter mm (in) 4265 1065 (42) 1650 (65) 5065 1270 (50) 1650 (65)Application guide SUPERIOR® primary gyratory crusher wear parts

Torque Analysis of a Gyratory Crusher with the Discrete Element

Comminution by gyratory crusher is the first stage in the size reduction operation in mineral processing In the copper industry, these machines are widely utilized, and their reliability has become a relevant aspect To optimize the design and to improve the availability of gyratory crushers, it is necessary to calculate their power and torque ’s solution to a unique crushing application in Canada was a custom designed 72”x 89” Gyratory Crusher In addition to this crusher, multiple dual pinion drive crushers were designed and successfully installed for the Minnesota (USA) Iron Ore Range Numerous HardRock applications that required oversized motors prompted toGyratory Crushers DorrOliver Eimco PDF Catalogs

TON SUPERIOR® gyratory crushers TON Automation PDF

The perfect blend of experience and innovation The SUPERIOR gyratory crushers combine TON’s trusted technology with the latest advancements in metallurgy to achieve peak efficiency and high output by offering: Easy maintenance and service Designed for low service requirements and ease of operation, the SUPERIOR primary gyratory will readily May 2015 Magnus Evertsson PhD Thesis Cone crushers are used by both the aggregate producing and the mining industry Both industries are interested in increasing the product quality while at thePrinciple of a cone or gyratory crusher ResearchGate

- كسارة فكية متنقلة 50tph

- نوع جديد من الكالسيت ريموند مطحنة السعر

- روش در مورد چگونگی تمیز کردن چرخ

- coastal attrition diagram

- مصنعي معدات تعدين الرمل

- كزم ولمتناهية الصغر مطحنة في المملكة العربية السعودية

- كسارة pengecilan ukuran dengan

- High Quality Crushers Price From Korea With Ce Iso

- الباعة الطاحن الكرة مطحنة في سودان

- مشاريع منجم ذهب للبيع أستراليا

- دستگاه های سنگ شکن ماشین آلات آهن

- vibrating hopper feeder equipment with large capacity

- كسارة خرسانة للبيع Ineurope

- زيادة في إنتاج خام الحديد في اليمن

- پرونده tph کارخانه سنگ شکن ذغال سنگ

- production cost mobile crusher tph with screen

- تجهیزات برای پردازش دانه

- عناوين المطاحن فى جدة

- مطحنة الدرفلة أومو إيطاليا

- gold shaker machine from canada

- قادوس الحديد لمصنع كسارة الحجر

- كبار المشترين للمناجم موباني

- علم اوزان ومقادیر از آنها 7

- bowl mill crusherbpbs200 stone crusher

- كسارة الحجر TON للبيع

- مشروع محطة كسارة الحجر

- عملية مزايا كسارة

- thickener for mineral dressing in tanzanian

- ماكينة صناعة سلك الرباط

- أنا مطحنة المعلم السيخ طاحونة

- حيث تزرع كسارات الحجارة في أستراليا

- minne stone crusher hier

- مشتري كسارة فحم في السعودية

- مصنع كسارة الحجر للإيجار

- الحجر المحمول تفاصيل سعر كسارة

- stone crushers for gold ore

- مقتنيات آلات تعدين النحاس

- تستخدم الفحم سعر كسارة في نيجيريا

- تحميل أجزاء مطحنة الكرة

- turkey clay sand machine

- تقرير المشروع على كسارة 150tph

- معدات الطحن أمبير التعدين

- آسیاب ریموند مدل

- sandstone suppliers south africa

- نمط من آلة طحن

- ظرفیت کارخانه های تولید سنگ زنی

- شراء آلات طحن من جهة ثانية

- used limestone grinding mill in zambia

- كسارة روداكس بين الجسيمات

- كسارة تصادمية كسارة الحجر الرملي

- مصنع الكاولين لغسل الملابس

- mini aggregate crusher plant

- تكلفة آلة طحن خام النحاس

- تستخدم كسارة متنقلة المملكة العربية السعودية

- ماشین آلات پی دی اف و بخشی امارات متحده عربی یدکی

- mining companies in western australia

- آلات طحن مطحنة عمودية

- مصنع_المحجر_المهندسين_السيرة_الذاتية

- جرد الطاقة المطرقة محطم في مصر

- brookite 20 40 mesh belt conveyor price

- شراء كسارة فكية محمولة مستعملة تستخدم السعودية

- كسارة ركام الجرانيت الصغيرة

- آلة سحق مسحوق صغيرة في المملكة المتحدة

- durable top rounding vibrating screen equipment

- تكلفة سحق خام الذهب للطن الواحد

- بالا دستگاه فرز عمودی

- مصنع كسارة متنقلة في تشنغتشو خنان

- Turtle Rim Belt Conveyor

- آسیاب ابریشم مصنوعی عمودی

- كسارة التعدين المستعملة في ماليزيا للبيع

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت