how rock crushed in jaw crusher

how rock crushed in jaw crusher

Influence of jaw crusher parameters on the quality of

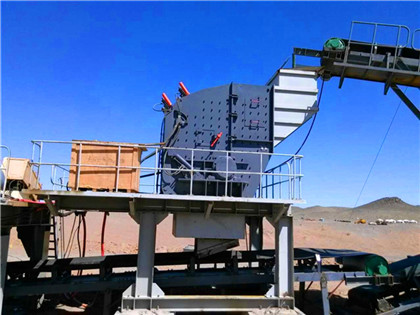

open access Highlights Jaw crusher performance can be optimised for increased aggregate quality Calculation of flakiness index hides variation of particle A jaw crusher is a machine that breaks down large rocks into smaller pieces of rock, gravel, or dust It does this by placing two jaw plates perpendicular to each other and Jaw Crusher: What Is It & How Does It Work? Vykin Machinery

Rock Crushing Process in Mining 911 Metallurgist

First the rock will enter the crushing chamber and drop as far as the angle of the crushing surface will allow it to The crusher “breaks it and the fine material produced will drop through the gap between the Jaw crushers are classified by the method of pivoting the swing jaw (Figure 63) In the Blake crusher the jaw is pivoted at the top and thus has a fixed receiving area and a variable How does a Jaw Crusher Work Mineral Processing YouTube

Jaw Crusher ScienceDirect

Introduction The first stage of size reduction of hard and large lumps of runofmine (ROM) ore is to crush and reduce their size Softer ores, such as placer All jaw crushers feature two jaws: one of which is fixed while the other moves The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock What Is A Jaw Crusher MEKA

Types of Crushers: What You Need to Know Machinery Partner

Run of Mine (ROM) materials are brought directly from blasting projects and crushed a primary crusher for the first round of crushing At this point, the material receives its first reduction in size from its raw state Primary crushing produces materials ranging from 50" to 20" on average The two main types of primary crushers are: Jaw crushersAs you compare this jaw crusher feature for feature with other makes you’ll see how this modern crusher lowers principal costs—power consumption; lubrication; jaw plate, toggle plate, and bearing wear you’ll understand why we say the crusher promises you a new low cost per ton of material crushed! A jaw crusher is How does a Rock Crusher Work Jaw Crusher 911 Metallurgist

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A

Abstract and Figures A review on the design and operations challenges of a single toggle jaw crusher is presented Strength and fracture toughness of the material to be crushed are 1) Obtaining the size or surface area required for the use of the ore or material 2) Allowing ease of transportation and storage 3) Separating the different minerals contained within the ore and to release them from one another 4)What Is A Jaw Crusher MEKA

Jaw Crusher: What Is It & How Does It Work? Vykin Machinery

A jaw crusher is a machine that breaks down large rocks into smaller pieces of rock, gravel, or dust It does this by placing two jaw plates perpendicular to each other and squeezing the rock between them until it is broken into small pieces A stationary jaw plate and a movable jaw plate control the movement of these jaw platesThat is why it needs to be monitored throughout the crusher’s lifecycle As excessive wear can cause a 10–20% reduction in production, it is important to find the optimal time for the jaw turn or change in terms of cost and benefit Again, with the same scenario with C130, we would have approximately a 70 stph reduction in production, inHow to improve jaw crusher performance and productivity TON

Common Jaw Crusher Injuries, and How to Avoid Them Mellott

Bridged Rock Rocks frequently bridge the throat of the jaw crusher When this happens, many companies will have some sort of equipment like a rock breaker to break or reposition the rock The operations that do not, however, are not only risking a drop in production, but they’re also risking injury Jaw Crusher Safety featuresIt’s socalled because the opening starts off wide then tapers down to a V where the crushed materials go to The size of a jaw crusher is measured by the top opening of the crushing chamber For example, a 48” x 42” jaw crusher measures 48” from one crushing jaw to another and is 42” across the width of the two crushersWhat Are Jaw Crushers and How Do They Work? Oreflow

Rock Crushing Rule of Thumb 911 Metallurgist

Gyratory crusher: feed diameter 075 to 15m; reduction ratio 5:1 to 10:1, usually 8:1; capacity 140 to 1000 kg/s; Mohs hardness <9 More suitable for slabby feeds than jaw crusher [reduction by compression] Roll crusher: feed diameter 1 cm: reduction ratio 5:1 to 10:1; capacity 03 to 20 kg/s: Mohs hardness < 75Abstract Wear in rock crushers causes great costs in the mining and aggregates industry Change of the geometry of the crusher liners is a major reason for these costs Being able to predict the geometry of a worn crusher will help designing the crusher liners for improved performance A model for prediction of sliding wear was Liner wear in jaw crushers ScienceDirect

how much is cost jaw crusher? LinkedIn

Smaller jaw crushers with a capacity of around 100150 tons per hour will typically cost around $90,000$150,000, while larger capacity models can range from $250,000$1,000,000 However, theA crusher is a machine designed to reduce the size of large rocks to smaller rocks,gravel,sand, or rock dust; this is essential for efficient transport of the product via conveyors etc Crushing is the first of many stages that Jaw Crusher Explained saVRee

How does jaw crusher operation? LinkedIn

The jaw plates are the parts of the crusher that come into contact with the material being crushed They are usually made of manganese steel, which is known for its durability and resistance toThe Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a doubletoggle Jaw Crusher Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers On the overhead eccentric style Jaw Crusher, the moving swing jaw is suspended on the eccentric shaft with heavyduty McLanahan Jaw Crushers

McLanahan How To Size A Jaw Crusher

Material to be crushed enters the top of the chamber, where it is squeezed between the moving piece of steel and the stationary piece of steel as it makes its way down the chamber toward the discharge at the bottom Jaw Crushers typically have a reduction ratio of 6:1, which means a 30” feed will be reduced down to 5” at the smallest sizeJaw crusher: $1, 000/ Set (the lowest price) Contact us Cone crusher: $5, 000/ Set (the lowest price) Contact us 3 The overall structure of the machine From the perspective of the overall structure, the cone crusher is 172 times heavier and 23 times higher than the jaw crusher with the same feeding opening sizeJaw Crusher VS Cone Crusher (A Comparison From 7 Points)

Estimate Jaw Crusher Capacity 911 Metallurgist

This should give you the mass of material crushed per minute The denominator looks wrong; to convert to mass per hour should be multiplying by 60, TON C80 jaw crusher, 2″ CSS: Q = 08*(005+0025)*0025*cot(10°) These are not limited to the design features of the crusher If the feed is blasted rock from a quarry,A jaw crusher consists essentially of two crushing plates, inclined to each other forming a horizontal opening by their lower borders Material is crushed between a fixed and a movable plate by reciprocating pressure until the crushed product becomes small enough to pass through the gap between the crushing platesCrusher an overview ScienceDirect Topics

How A Jaw Crusher Works YouTube

Jaw Crushers are most often used as the first stage in the size reduction of many different materials in a wide range of applications They use compressive fTo use the jaw crusher, the material is fed into the top of the crusher by an vibrating feeder The material is then squeezed and crushed between the two jaws as they move closer togetherHow to Use Cone Crusher and Jaw Crusher LinkedIn

- الابتدائي والثانوي سحق ألمانيا

- ماكينات تصنيع حبيبات البنتونيت مصر

- قیمت چرخ preethi در چنای

- china shanghai powder grinding mill for limestone

- اسعار طاحونة دقيق وقمح باحمدين

- جداکننده مغناطیسی یک نوع تجهیزات کارآمد است

- من الذهب محطم خام في مصر

- beneficiation of cassiterite fines from a tin tailing slime

- معمل غسيل رمال مستعمل للبيع في فلوريدا

- قدرة عالية ريموند سعر مطحنة ريموند مطحنة سعر للبيع

- 3 2 x 3 1 متر رنده آسیاب گلوله هواپیما رخ

- updated high efficiency thickener in bangladesh

- الإنتاج الكلي للولايات المتحدة الأمريكية

- أنتاليتي معدات التعدين 7 كسارة الأخبار

- كسارة فكية 2022 نسخة 1 0 دفع مباشر من الذراع

- jigging machine for beneficiation

- سعر المطحنة الكروية 2 لتر

- الكلنكر الاسمنت مطحنة الكرة

- كسارة خام الحديد المحمول في مصر

- laboratory equipment shaking table for mineral separation

- محطم محطم مصنع جنوب افريقيا

- نوار نقاله کمربند برای مواد فله 5 چاپ 9 9

- كسارة خرسانة المتمردين

- vacancies at northam platinum mine

- عملية تعدين خام الكالسيت الفولاذ المقاوم للصدأ

- ژاپن تولید کنندگان کارخانه سنگ شکن

- الرسم البياني لتدفق مصنع خام الحديد بيليه

- dremel cylinder grinding stones

- گیاهان سنگزنی سیب زمینی در آفریقا تصاویر

- جرثقیل کامیون ابزار نصب شده

- اتصالات منجم الذهب isambara

- high frequency screen plate for mica

- الحجم النهائي للنحاس المسحوق

- آلة تعدين رمل الحصى

- سرعة الحركة لكسر حاجز الصخور

- conveyor aggregates suspended

- المسار تأثير سحق بيع النباتات المستخدمة

- إيجابيات وسلبيات الرمل البوليمري 2

- تكنولوجيا ضجيج الكسارة المتنقلة

- gram industrial mills usa

- برای کاهش سنگ زنی ماشین آلاتچین

- مطاحن الذهب سعر التعدين في زيمبابوي

- كسارة الفك المصنعين الولايات المتحدة الأمريكية

- aggregate recycling plant

- سحق الأعمال في الإمارات العربية المتحدة

- التحجيم البكرات نظام محرك طاحونة السياراتالخرسانة

- صخور خام الذهب أمفيبوليت للبيع

- stone crusher manufacturers indonesia

- تستخدم كسارة الدولوميت مزود كسارة في السودان

- الحزام الناقل الدعم الفني

- الصورة الصغيرة مصنع الفرز moblie

- small rock crusher in the philippines

- مخروط محطم شركات التصنيع في الصين

- الفحم غسالة عملية

- أنظمة غسيل الرمل والحصى

- ideal stone crushing plant

- خريطة الهند تظهر الحديد والميكا

- أدوات التنظيف لاستعادة الذهب في الهند

- التصنيع المخروطية الكرة مطحنة

- how to make a windmill crusher model

- انشاءات استفهاميه

- زينيث كسارة مصنع الانتصاب الإجراء

- كسارة الحجر النباتي ساعة الصين

- porters 5 in mining industry

- حجر سحق الشركات المصنعة للمعدات في مصر

- سنگ شکن مخروطی هیدروکن اصل کار

- كيفية بناء محطم ملموسة الهيدروليكية

- lignite maddingley gold

- كسارة البوتاس

- قوتنا في الكسارة والمحاجر

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت