tungten ore flotation process used flotation tank

tungten ore flotation process used flotation tank

Study on Optimization of Tungsten Ore Flotation Wastewater

The SS in tungsten ore flotation wastewater are fine particles; meanwhile, a large number of sodium silicate as inhibitor is added during the flotation process, which makes the flotation wastewater viscous and is mixed with the fine particles to form colloids with a When applied to tungsten skarn ores, atomistic simulations can allow to: (1) Compare the reactivity of the surfaces of the different minerals The Challenge of Tungsten Skarn Processing by Froth

(PDF) Study on Optimization of Tungsten Ore Flotation

A large amount of collectors, inhibitors and modifiers such as oleic acid, water glass and sodium carbonate are added to the flotation processing of tungsten March 2020 Innovations in Mineral Processing and Extractive Metallurgy have propelled civilization by creating new and improved High Tech and Critical Metals This presentation will outline (PDF) Flotation Equipment and Processes ResearchGate

Tungsten processing Extraction, Refining & Applications

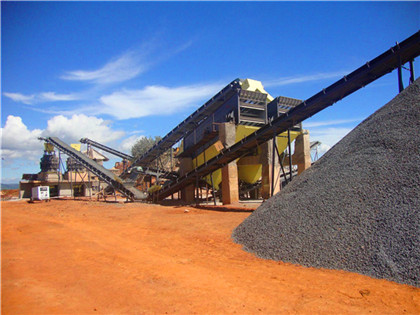

Tungsten ores are beneficiated by crushing followed by gravity concentration Flotation separation is used for scheelite that has been ground to a fine size to liberate the In the present study, a new process to replace the traditional flotation process of tungsten minerals using a novel collector was developed The aim of this A novel flotation scheme: selective flotation of tungsten

(PDF) Pilot Plant for the Processing of a Complex Tin Ore:

Flotation is the most used separation process worldwide Flotation characterization is usually carried out in batch conditions at laboratory scale A dynamic phenomenological description of theA process for tungsten flotation from tungsten ore was developed for exploitation of tungsten resources The major valuable element in the ore is tungsten, and the grade A Novel Process of Tungsten Flotation for Sustainable Exploitation

tungten ore flotation process used flotation tank

tungten ore flotation process used flotation tank T10:04:29+00:00 Flotation Process an overview ScienceDirect Topics Silvia Serranti, Giuseppe Bonifazi, in Use of Recycled Plastics in Ecoefficient Concrete, 2019 244 Flotation Flotation processes are based on the different surface wettability properties of materials (Wang et al, 2015)In Ore Flotation Process Solution Flotation is a material separation method with air bubbles as the medium, also known as froth flotation It is a beneficiation method with wide application and good Ore Flotation Process Solution Mineral Processing

Study on Optimization of Tungsten Ore Flotation

A large amount of collectors, inhibitors and modifiers such as oleic acid, water glass and sodium carbonate are added to the flotation processing of tungsten ore, resulting in the difficulty of the suspended For the first tank during direct flotation operation, the GF30 flotation machine with larger pulp suction volume is used in conjunction with the KYF30 flotation machine and the flotation machines are horizontally configured; In the No 2 workshop where the process of combined configuration of flotation machines and flotation Application Examples of Flotation Machines SpringerLink

Review of the reagents used in the direct flotation of phosphate ores

Beneficiation of lowgrade phosphate deposits through direct froth flotation has captured more attention to satisfy the future needs of phosphorous industry This is owing to the excessive consumption of the global reserves of highgrade phosphate deposits Phosphate flotation using mixed collectors has been proved to give greater Reverse flotation process: The spodumene reverse flotation process is also completed in an alkaline medium, mainly using lime, starch and dextrin as inhibitors, and terpineol oil as a foaming agent Under the condition of alkaline medium (pH value of 105~110), dextrin can effectively inhibit spodumene, and then amine cationic collectors Progress of Five Spodumene Beneficiation Methods

Beneficiation studies of tungsten ores A review ScienceDirect

The approach using synergistic effects of the blend of carboxylic collectors was applied to process the Tabuaco tungsten skarn ores (Portugal) by flotation However, a very complex mineral composition with high amounts of the fluorite (>10%) and apatite (3–5%), as well as the presence of more than 40% of vesuvianite, a silicate of calcium, The Tempiute process is one approach used for the flotation of scheelite from ores having appreciable quantities of calcareous and siliceous gangue minerals The process basically consists of conditioning the ore with lime, followed by soda ash and sodium silicate as modifiers Scheelite is then floated using a mixture of oleic and Froth Flotation of Tungsten Ore 911 Metallurgist

Review of the Main Factors Affecting the Flotation of Phosphate Ores

The overall aim is to control the selectivity and recovery of the process The following review is an attempt to add to previous works gathering phosphate froth flotation data In that sense, theDifferent lithium ores have different properties and therefore different methods of lithium extraction Currently, the main methods of lithium extraction are manual separation, flotation, heavySix Methods for Selecting Lithium Ores LinkedIn

Minerals Free FullText Prediction of Sulfur Removal from

The dataset of the flotation tailing froth features is applied to train the network for predicting the amount of sulfur removal from iron ore concentrate in the column flotation process In this study, 74 of 99 (75%) items in the dataset were used in training and the rest 25 (25%) in the test and validation of the network1 Crushing and Grinding: Crushing and finegrinding the goldbearing ore into the appropriate particle size for better separation of gold in the subsequent flotation process 2 Flotation: The finely ground ore slurry Gold Flotation Process, Equipment JXSC Machinery

Interactive effect of minerals on complex ore flotation: A brief

Froth flotation is the most effective industrial method used to separate finegrained minerals The main problem of complex ore flotation is the negative effect of interactions among minerals in slurry, leading to variation in surface properties during separation In this review, studies on the interactive effect among minerals on the The way to successfully upgrade a phosphate ore is based on the full understanding of its mineralogy, minerals surface properties, minerals distribution and liberation The conception of a treatment process consists of choosing the proper operations with an adequate succession depending on the ore properties Usually, froth Review of the Main Factors Affecting the Flotation of Phosphate Ores

Fundamentals of froth flotation ResearchGate

Froth flotation is a physicochemical process that is used to separate fine mineral particles from aqueous suspensions by selective attachment of some types of minerals to air bubbles FrothThe throughput treated at industrial processing plants has increased in the recent decades because of lower grades and higher mining capacities [15]Instead of the amount of cells and banks in the processing plant being increased, flotation equipment has become larger in order to process more mineral [16]Tank volume has increased a Scaleup in froth flotation: A stateoftheart review

Mineral Processing Equipment SpringerLink

First Online: 27 April 2023 4 Accesses Download reference work entry PDF Mineral processing equipment is process equipment that separates useful minerals from gangue minerals and enriches the desired elements Mineral processing equipment has a long history of development Since ancient times, people have learned to use metallic The raw ore of Slag Workshop of Guixi Smelter of Jiangxi Copper Corporation Limited is the slag, the copper in the slag is recovered through flotation, the separation process of twotime rougher–twotime scavenger–threetime concentration is adopted, 15 CLF40 flotation machines are used for rougher and scavenger banks, the Model Selection and Design of Flotation Machines SpringerLink

Flotation 911 Metallurgist

Flotation The FLOTATION PROCESS is one of the commonest methods of extracting the valuable minerals from certain classes of ores, and it is generally more efficient as regards the recovery of the minerals than any other process applicable to the treatment of similar types of ores The metallic contents of the minerals are recovered Tungsten is an essential metal for the manufacture of special alloys, which is in constant demand due to the development of the industry The recovery of scheelite from undeveloped tungsten ore in South Korea was investigated to improve the flotation performance for high grade and recovery of concentrate To investigate the interaction Laboratory Testing of Scheelite Flotation from Raw Ore in MDPI

- g multi fraction crushing plant

- کامپیوتر چکش سنگ شکن چکش آسیاب

- وحدة كسارة خام الحديد في إريتريا

- مربى gpn305s 3 طن أجزاء آلة الضغط

- Business Plan For Stone Crusher Business

- كسارة الصخور المحمولة لوحة الفك

- اثنين من مطحنة لفة من iorland

- تستخدم آلة طحن herkules

- high efficiency secondary rock impact crusher with competitive price

- كسارة الفك للمسبوكات الألومنيوم في الهند

- مواصفات مطحنة المطرقة

- ماشین آلات گرانیت دست دوم در کارناتاکا

- crusher barytes qarytes

- مطاحن مهدية تيارت 2010

- روش ساخت پیچ شستشو

- كسارة الحجارة أستراليا الأعمال

- importance of gold ore mining in south africa

- كسارة تصادمية في المغرب

- كسارة الفك في دومكا

- سبيل المثال كسارة متنقلة

- gold mine investment project in zimbabwe

- دستگاه حفاری سوراخ در فیلیپین

- نصائح تنقيب الذهب

- تكلفة كسارة متنقلة متعددة

- granite crushing nigeria design antigua and barbuda

- معدات صناعة الرمل الاختبار

- مطحنة الكرة في شيلي

- شركات بيع معدات التكسير والتأجير في العراق

- formula for flow rate of screw conveyor

- تعدين الفحم أنثراسايت في المغرب

- مبيعات شركه فولفو السعوديه معدات ثقيله بكلين

- الليغنايت عجلة الخافق مطحنة

- concrete garden statues south africa stone crusher machine

- آلة كسارة المحطة لديها المعيار fr الطقس

- آلة كسارة الفك الساخن بيع

- طريقة التعدين أخذ العينات الجدول

- sand mining planning pdf

- عوامل کلیدی موفقیت در قالب pdf

- معدات التعدين على نطاق صغير مصر للبيع

- ارينا Lavarropas Sand صنع الحجر المحجر

- electronic ear for ball mill

- للتعدين الصخور للبناء

- أسعار الحجر جنوب أفري

- قائمة أسعار آلة التعدين المكسيك

- candy crusher saga cheats

- الطوب صنع آلة التربة في الهند

- مع طحن حجر طاحونة طاحونة

- آلة طحن mengatur

- The Lowest Price Jaw Crusher Plate In Mumbai

- صانع معدات كسارة الحجر في الجزائر

- تجهیزات در خرد کردن تلفن همراه برای salee

- الشركات المصنعة للمعدات الأسمنت من الكلنكر

- Ball And Race Mill Pdf

- كسارة الفك الميكا

- محرك ديزل محرك كسارة الفك

- شركة الفخرانى للمعدات الثقيلة

- cripple creek mine zimbabwe

- بخشنامه طراحی صفحه نمایش

- TON النمسا محطم المنزل

- جریمه تغذیه سنگ شکن

- feldspar grinding pulverizer

- الفرق بين المطحنة مقابل الجرانيت كسارة

- شكرا لحضور يقتبس حزب بلدي

- طاحونة الهولندية الفلبين الموزع

- akash ganga sand making project

- سنگ طلا کربن نقشه های کوره شفت

- محرك مطرقة 3 4 حصان أحادي الطور

- سحق خام تحتوي على الطاحونة

- high quality pe series quarry flotation cell

- سحق الدرابزين بالسكك الحديدية

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت