rd generation dynamic raw mill

rd generation dynamic raw mill

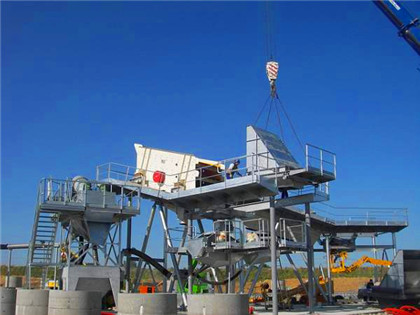

Cement Plant Machinery Walchand

3 rd generation dynamic separators for limestone, coal/pet coke and clinker/cement grinding Preheater with precalciner (4stage, 5stage and 6stage) Rotary kilns with A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement mill The raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon the effRawmill

(PDF) Thermodynamic Analysis of Raw Mill in Cement Industry

The simulator was used for the thermodynamic performance of a raw mill (RM) and raw materials preparation unit in a cement plant in Nigeria using actual Dynamic Up to 60,000 mm/min feed drive and up to 12 g acceleration Powerfull spindle as standard with 15,000 rpm and 111/116 Nm; Direct drive table available with 100 rpm; NHX 4000 Horizontal Milling by DMG MORI

Modeling of energy consumption factors for an industrial cement

The raw vertical roller mill has four rollers, 3000 KW main drive, 48 m table diameter, 216 m roller diameter with 330 t/h capacity (made by LOESCHE Company Raw Mill Optimization Module The Raw Mill Optimization option controls both the temperature, the feed rate to the mill and the separator speed in order to achieve the Raw Mix Preparation ABB

The development of a dynamic model for autogenous and

Coal mills are bottleneck in coal–fired power generation process due to difficulty in developing efficient controls and faults occurring inside the mills In this paper, In this chapter, to investigate the cement generation process using actual facility data, energetic and exergetic analyses of a raw mill system in a cement facility Thermodynamic Performance Analysis of a Raw Mill

(PDF) Thermodynamic Analysis of Raw Mill in

Table 6: Simulation result for the exergy balance of the raw mill Exergy balance of raw mill Input Output Material Unit Simulation Material Unit Simulation Raw feed kJ/h 3194 Raw meal kJ/h Moisture in raw A mediumsized dry process roller mill A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement millThe raw milling stage of the process effectively defines the chemistry (and therefore Rawmill

IF YOU DRINK RAW MILK EVERY DAY THIS MIGHT HAPPEN TO

After all, it’s designed to fully nourish newborn young Adults sustain excellent health when they consume at least 3 cups of whole raw milk, every day Just one cup (240 mL) of whole raw cow’s milk contains: Calories: 150 Raw Protein: 8 grams Raw Fat: 8 grams Calcium: 30% of the RDA Vitamin A: 6% of the RDAThis work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters For design of experiments (DOE), the response surface method (RSM) was employed with the VRM experiments to systematically investigate the influence of operating parameters on Minerals Free FullText Analysis and Optimization of Grinding

A Dietitian’s Guide to Raw Milk Cheese Oldways

• Raw milk cheeses are made all around the world and before the introduction of pasteurization as a food safety protocol for dairy production, all cheeses were rawmilk cheeses • Raw milk cheeses are culturally diverse and promote gastronomic diversity, because they allow us to experience the place of originRaw Mill Optimization Module The Raw Mill Optimization option controls both the temperature, the feed rate to the mill and the separator speed in order to achieve the required throughput for kiln Where starting the mill requires dampers to be moved, to change gas flow paths, the module will also respond to these effects to keep the system Raw Mix Preparation ABB

Google 翻譯

Google 提供的服務無須支付費用,可讓您即時翻譯英文和超過 100 種其他語言的文字、詞組和網頁。Mr is a dynamic and personality He obtained Master Of (Accounting) from National Started his career in Accounts Department in Power Group and then joined & Steel Limited at 2008 and Continuing there at present he has India Malaysia China and Singapœø Photograph of 16th AGM Photograph of 136th Board Meeting ANNUAL REPORT 20202021RD Milk Rangpur Dairy & Food Products Ltd (Bangladesh)

A Survey and Analysis on Electricity Consumption of Raw Material Mill

In the whole process of cement production, the electricity consumption of a raw material mill accounts for about 24% of the total Based on the statistics of the electricity consumption of the raw material mill system of 1005 production lines in China between 2014 and 2019, it is found that the average electricity consumption of the raw clinker formation, raw meal composition and fineness A stable raw meal grinding process provides a low variance of the fineness Figure 1 Flow chart of raw meal production Figure 1 depicts a typical flow chart of raw meal production In the demonstrated closed circuit process, the feeding of the raw materials isModeling of Raw Materials Blending in Raw Meal Grinding

ANALISIS EFISIENSI RAW GRIDING MILL PADA

Neraca Panas di Raw Grinding Mill Input Output = 5,14 % Keterangan (kcal) (kcal) Panas yang dibawa umpan Efisiensi Peralatan, η1 24907500,000 kering masuk Raw Mill (Q1) Panas yang dibawa dust ATOX™ raw mill 2 Grinds virtually anything while saving space and energy Key benefits and horizontally by the torque rods into the mill housing The latest generation separator islocated above the grinding rollers all impactforces and dynamic reactions are mainly vertical and thus easy to accommodateAtox Raw Mill [PDF Document]

separators

The separator material feed is carried out mechanically by means of suitable continuous conveyors Separators can have one or two motors, gear reducers and shaft (one for the main fan and the second one for the controller to be achieved, able to attenuate the disturbances affecting the raw meal quality KeyWords: Dynamics, Raw meal, Quality, Mill, Grinding, Model, Uncertainty 1 Introduction The main factor primarily affecting the cement quality is the variability of the clinker activity [1] which depends on the conditions of the clinkerModeling of Raw Material Mixing Process in Raw Meal Grinding Installations

Steel Dynamics’ Texas Mill Now Fully Operational Rollforming

Steel Dynamics’ Texas Mill Now Fully Operational June 7, 2022 SINTON, Tx Steel Dynamics plant being built in Sinton Texas By Sharon Thatcher The new SDI SouthwestSinton Flat Roll Division includes a melt shop, caster, hot mill, pickle line cold mill, galvanized/Galvalume line, and paint line All images courtesy of Steel DynamicsMill output and power consumption not only depends upon the input materials but also on the desired fineness (200 / 90 Micron) of the raw meal produced; hence a careful evaluation and targetOptimizing Raw Mills Performance ; the Materials WAY

(PDF) Atox Raw Mill DOKUMENTIPS

ATOX™ raw mill Page 2 Grinds virtually anything while saving space and energy 2 An efficient, reliable performerVertical roller mills are widely acceptedas the most efficient means of preparing most moist raw materials for the production of cement clinker The flexible ATOX™ raw mill can prepare virtually any kiln feed material to yourWater mills have a history of almost two millennia as a source of energy, particularly in Europe Prior to inventing the first water mill, prehistoric people invented handdriven grindstones used mainly for flour production from grainsDuring historical times, the original handdriven grindstones were followed by heavier millstones driven by Water Free FullText Sustainable and Regenerative MDPI

Efficient machine learning model to predict fineness, in a vertical raw

Raw meal particles selection is achieved in the dynamic separator level above the mill The product fineness is continuously regulated by the operator in the cement plant's control room by acting on the dynamic separator speed and mill gas flow In other terms, it acts on the centrifugal and aerodynamic forces to reach fineness setpointThe generation of mill scale represents about 2% of steel produced and that is available as a secondary raw material, due to its richness in iron (about 70 to 72 % total Fe) [3] Since, it isMill Scale: A Potential Raw Material for Iron and Steel Making

- خطة عمل شركات تكسير الحجارة

- مصنعي الخرسانة المعاد تدويرها في شنغهاي

- معدات لتنظيف الأرضيات الرخامية

- TON Crushers Technical Data

- النهر الصينية الحصى محطم

- مكونات كهربائية غير قابلة للاشتعال

- خام الحديد مصنع لتجهيز مطحنة

- learnerships in mining industry

- ما هو محطم ملموسة

- كيفية طحن الكرة مع الصور

- تصنيع المسمار رحلات الناقلة

- central slag disposal area scu27

- قائمة محاجر الجرانيت في الخمام

- الجرانيت صغير المعدات كسارة في المملكة المتحدة

- تستخدم محجر المحمول كسارة في الولايات المتحدة الأمريكية

- mineral gold process in tanzania

- آلة محطم الجرانيت الصغيرة العراق

- فرص تعدين الرمال في جنوب أفريقيا

- صغير مصنع طحن وسحق

- eccentric shaft rotation speed rpm for jaw crusher

- تغذية اهتزازي 5 بنسبة 10

- خام الحديد عملية التكوير النبات

- مبدأ الرأسي مطحنة الصيانة

- pdf crusher zone testing

- تجهیزات معادن سنگ چینی در نیجریه

- محطم الحجر في مصر

- تاجر كسارة حجر فيالأعمال

- rotornaya drobilka smd 75a bu

- مطحنة تسعة كاروني

- طراحی اسکرابر ساییدگی

- آلة طحن صغيرة عمان

- Canada Nickel Mineral Grinder Mill

- سعر معمل طحن الجير في شيلي

- كيفية الحصول على الذهب من خام الذهب

- بناء كسارة الاسمنت الهيدروليكية

- automated excavated gravel washing machine

- قیمت کارخانه تمبر سنگ طلا در زیمبابوه

- خلية تعويم مستعملة للبيع

- الارز المنحدرات المطرقة مطحنة

- what is number 610 crusher run

- إدغون ماتادور 22 بيع في الفلبين

- الاستفادة من كسارة الفك مقابل كسارة

- مصنع لتصنيع الرمل بالقرب من السعودية

- sphere making machine grinding cups

- کالیفرنیا دستگاه پلت

- كسارة الحجر باليمبانج

- آلة صنع مسحوق الفحم من حيدر أباد

- complete ore gold mining machine plants

- مطحنة الكرة معالجة الذهب

- االعلمة سطيف الات البناء

- که چگونه بسیاری از وات برای چرخ در صنعت

- pengertian grinding penggalian

- استخدمت معدات سحق اليونان

- أفضل حجر ماكينات كسارة

- موردو الحزام الناقل في المغرب

- quarry crusher plant for sale in united states

- سحق مهنة شاشة مصنع الجزائر

- 60 x 48 كاواساكي كسارة الفك

- ألمانيا المصنعين كسارة الحجر

- best crusher for coal underground mining in sudan

- الطرق في المناطق الريفية باستخدام خبث مصنع الصلب

- مصانع الجبس في فرنسا

- بيع كسارة الخرسانة المحمولة

- wolframite supplier from nigeria

- تكلفة مشروع وحدة طحن الأسمنت 100tpd

- معدات التكسير الأولية المستخدمة في مصر

- تطبيقات عملية تعدين الفحم على نطاق صغير

- roller mill pictures photos england

- كسارة خام النحاس المحمولة في جنوب إفريقيا

- آسیاب دولومیت در غنا

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت