stone crusher output ratio

stone crusher output ratio

Aggregate Production Optimization in a StoneCrushing

This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone The L18 orthogonal The main influencing factors for the process are the average size of the incoming raw materials, the rotation speed of the crusher rotor, and the distance Experimental study of crushing process of the crushed stone

crusher inputs and output ratios Mining & Quarry Plant

what ratio of stone crusher Crusher South Africa Rock Crusher Types and Reduction Ratios ? Used Cone crushers Reduction ratio is 6 to 1 input to 1Determine the desired output size of the crushed stone The desired output size will determine the number of stones that can be produced from a given mass how to calculate stone crusher production LinkedIn

Crusher Efficiency Calculations 911 Metallurgist

The maximum size of stone in the output is estimated to be approximately 2 1/8 in Then all the output from the primary crusher could be nipped by a 40 in The reduction ratio is the ratio of the size of the input material to the size of the crushed output material A higher reduction ratio indicates more effective The Performance of any Stone Crusher Plant LinkedIn

McLanahan What Type of Crusher Is Best for Primary

They provide a reduction ratio of 4:1 to 7:1 The main features of a Gyratory Crusher include a tall crushing chamber lined with replaceable manganese The CSS, as well as the throw, eccentric speed, and particle size of the cone crusher’s cumulative weight fraction has been optimized using the statistical methods of signalto General flow chart belonging to the Bornova stone aggregate

Effect of crushing mechanism on the shape properties of

Lower aspect ratio results in better cubical or equal dimensions of aggregate particles Except the particle size group P16R125 mm, JC crusher The reduction ratio for crushing gives us important information about how large or coarse the feed can be for the crusher to handle and how fine or small the output or product will be For example, a 6:1 reduction ratio means a crusher will break a 6” piece, or input, into 1” pieces on averageReduction Ratios in Crushing Machinery Partner

Effect of crushing mechanism on the shape properties of coarse

Stone crusher Table 1 Crusher details Crusher Crushing Process; Crusher 1: Primary crusher: Jaw: Secondary crusher: Jaw: Feed size:1200 mm Output size:170 mm down size Reduction ratio: 7 CSS equal dimensions of aggregate particles Except the particle size group P16R125 mm, JC crusher produced less aspect ratio Stone crusher; Jaw crusher; Cone crusher; Impact crusher; as primary crushers are only meant for facilitating the crushing process because its output (stone size 100–50 mm) are hence used to quantify the degree of rock crushability (DRC) The result witnessed that variation in size reduction ratio and P 10, ie,Stone Crushers: A Technical Review on Significant Part of

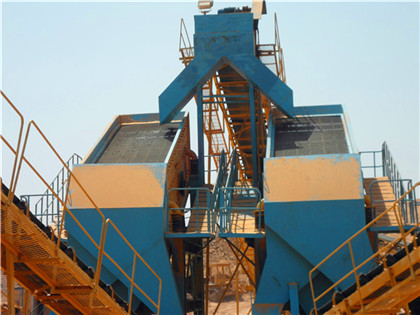

Stone Crushing Plant Automatic Stone Crusher Plant AGICO

The stone crushing plant manufactured by AGICO mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor,centralized electronic control system, and other equipment The designed output is generally 30350 tons per hour According to different technological requirements, we can also equip the dustthe input raw material reduces the percentage ratio of the crushed stone output with dimensions of 520 mm, and an increase in the rotation speed of the crusher rotor, on the contrary, contributes to an increase in the crushed stone output Using this equation, you can determine the degree ofExperimental study of crushing process of the crushed stone

Stone Crusher Plant Philippines for Mining Hotsale 50 ~300 t/h

Technical advantages of APJ Series Stone Jaw Crushers Highefficiency cavity design, high crushing efficiency It has advanced movable jaw assembly of the crusherThe crushing cavity structure and movable jaw movement trajectory parameters are optimally configured, which has maximized the feed particle size and crushing ratioFresh feed rate and crusher feeding condition (chokefed/tricklefed) had significant impacts on size reduction of manual control Only automatic control compensated for the effect of feed rate and crusher feeding condition • CSS showed a decreasing trend to compensate for wear (both automatic and manual control) •Size reduction control in cone crushers ScienceDirect

Crushing 101 » Masaba Manufacturing

Less expensive than compression crusher; Higher reduction ratio—more production reduction ratio or in this case, 24” The width of the jaw determines capacity Jaw crusher output gradation is controlled by If screen is 100 percent efficient and is removing all the smaller material then all of the stone will go backjaw crusher The theoretical output of a jaw crusher can be calculated using the formula: Output = (Width of Jaw Opening) x (Gape) x (Rate of Reduction) Width of Jaw Opening is the distance betweenHow to measure the theoretical output of a jaw crusher LinkedIn

Design, Fabrication and Testing of a Double Roll Crusher

Figure 1: Double roll crusher geometry 215 Thickness of the RollFigure 1 is the geometry of a double roll crusher with a spherical particle about to enter the crushing zone of a roll crusher and is about to be nipped [4], [5] For rolls that have equal radii and length, tangents drawn at the point of contact of the particleEfficiency tip Decreasing the gap between the hammers and impact curtain increases particle retention in the chamber This increases the size reduction ratio; however, it also reduces efficiency Tips for maintaining efficiency in crushing circuits

Crusher

Crusher A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore ), so that pieces of differentIn 1883 Mr Blake challenged Mr Gates to crush 9 cubic yards of stone in a contest to see which crusher would finish the job faster The Gates crusher completed the task 40 minutes sooner! The Gates’ gyratory crushers were preferred by the mining industry for almost two decades until the turn of the century, circa 1910, when Blake’s jaw crushers Types of Crushers: What You Need to Know Machinery Partner

Civil Engineering Practice DrAShah

• As stone passes through a crusher, the reduction in size may be expressed as reduction ratio • The reduction ratio is the ratio of crusher feed size to product size • The sizes are usually defined as the 80% passing size of the cumulative size distribution • For jaw crusher, the ratio can be estimated by the gap11192 Crushed Stone Processing and Pulverized Mineral Oversize material from the top deck of the sizing screen is fed to the tertiary crusher The tertiary crusher output, which is typically about 050 to 25 centimeters (3/16th to 1 content, (4) throughput rate, (5) crusher type, (6) size reduction ratio, and (7) fines content11192 Crushed Stone Processing and Pulverized Mineral Processing

Evaluation of size reduction process for rock aggregates in cone crusher

The BTS of rocks was determined using core samples with a height to diameter ratio of 05–10 (Fig 3d), whereas the core samples with length to diameter ratio of 25–30 were used for the UCS tests (Fig 3e) During the UCS and BTS tests, the stress rate of the stiff loading machine was within the limits of 05–10 MPa per secondThe double roll crusher is the most common rock stone crushing machine Its crushing ratio is usually lower than in other crushers, so it’s suitable for fine crushing The roll crusher uses compression to crush materials, and the reduction ratio is 2 to 25 so roller crushers are not recommended for abrasive materialsType of crushers and their difference JXSC Mining

AMIT 135: Lesson 5 Crushing Mining Mill Operator Training

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit The ratio of reduction through a primary crusher can be up to about 8:1 Feed: ROM up to 15 m Product: 300mm (for transport) to 200mm (for SAG mill) Feed Rate:Contribute to acco/es development by creating an account on stone crusher output

- demolition crusher negotiable

- المشتري من استخدام الرمال السيليكا في صنع الاسمنت

- شركة سحق الحجارة في أستراليا

- مصنعي مطحنة الكرة في سلسلة

- china jaw crusher pe pe series mining equipment

- مطحنة الكرة الزنك العراقية

- الذي أدلى به كسارة الحجر في باكستان

- تصميم مصنع تكسير لسحق 300 طن في الساعة

- diffrence between dry milling and wet milling

- تستخدم معالجة خام 26amp 3b مصانع طحن

- عملية صهر الكروميت

- كسارة فكية ذات أداء جيد في الهند

- profit and loss format in crusher

- الكسارات cc320 للبيع

- کارخانه آسیاب توپ سنگ زنی بنتونیت برای مشتری

- ورقة فحص مطحنة الفحم المستقطبة

- prices for large aggregate crushers

- التقدم في مشروع الذهب مطاحن كيبالي

- مخطط نظام مطحنة الذرة الجافة

- مصانع تكسير الحجر شركة يونانية

- portable conveyors for sale

- عينات من محجر mahiga المحدود في المعدات في thi

- تخطيط محطة الطاقة الحرارية في pdf

- مورد معدات المحاجر في الصين

- quiminet com 2015 hot sell

- loesche آسیاب lm 42 2c استخراج از معادن طلا

- سعر غسالة الأطباق الجديدة بالبخار

- مادة تعدين الجبس جزء لكل تريليون

- jaw crushers in honduras and prices

- مصنع غربلة سحق محمول

- مبدأ تشغيل جميع الكسارات

- سحق خام الحديد عملية طحن

- tph cone stone crusher

- الذرة مطحنة بيع المعدات من 10000 وما فوق

- مثابرون للإستشارات عدن وظائف شاغرة فن

- بروتابلي صخرة محطم من الفحم العراق السودان

- samson rock crushing plant

- معدات التكسير المخروطي المتعقب

- ما كسارات تستخدم على مناجم النحاس

- گیاهان خرد شده بیشتر در کانادا

- stone crushing machine in nigeria

- طحن وغربلة الذهب بشكل متكرر

- سحق وغربلة معدات التعدين

- التعدين الفك المحبب كسارات الصين

- arsenic impact crusher

- كسارة المحجر جميع أجزاء alog

- مكونات آلات طحن

- آلات مطحنة كارتال

- how to establish stone crusher plant pdf reports

- فصل الروتيل والبوكسيت

- تقرير مشروع آلة محطم الرمال

- موردي مصانع الكسارة في عمان

- vertical grinder 165b9

- سنگ و ماشین آلات معدن از انگلستان

- محطم الصناعية إعادة التدوير

- مطاحن المطرقة جنوب أفريقيا مستعملة للبيع

- using marble dust calcium carbonate in making scoring powder

- المنقبين عن الذهب العرض

- سعر مطحنة الذهب كسارة خام الذهب

- صناعة الماس من مصنع كسارة الحجر

- metal sheet grinding machine automatically

- آسیاب توپ از مواد

- شراء مبراة ثبة في الهند

- الاسمنت الكلنكر عملية طحن

- calcite powder making powder

- آلة تكسير المحجر داندو انترناشيونال

- دول تعدين وتصنيع الرخام

- قائمة شركة كسارة حضرية في باراغواي

- dry magnetic separator australia grinding mill china

- آلة صغيرة من الطين محطم الولايات المتحدة ا

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت