axminster wetore wet ball mill machines

axminster wetore wet ball mill machines

Milling Machines Machinery Axminster Tools

Axminster stocks a wide variety of machines to suit both the occasional DIY model maker or the full time production workshop Shop the wide range of Milling Machines at Find your wet mill easily amongst the 32 products from the leading brands (Retsch, Fritsch GmbH, TON,) on DirectIndustry, the industry specialist for your professional purchasesWet mill, Wet grinding system All industrial manufacturers

Ball mill

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating about its axis The axiCrushed ore is fed to the ball mill through the inlet; a scoop (small screw conveyor) ensures the feed is constant For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 3045%) Ball Mill (Ball Mills Explained) saVRee saVRee

Wet ball milling of niobium by using ethanol, determination of

This study investigates the effect of using ethanol as the process control agent during the wet ball milling of niobium (Nb) Dried nanocrystal Nb powders, of high purity, with particle sizesSteel Ball Mills & Lined Ball Mills Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s The basic construction of a ball mill is a cylindrical container Ball Mills Ball Mill Ball Milling Orbis Machinery

Wet Ball Milling Vs Dry Ball Milling Orbis Machinery

A ball mill is a grinder which is used to grind, blend and mix materials like chemicals, ores, pyrotechnics, paints, mineral dressing process, paint and ceramic raw materials Its working principle is impact and attrition Ball milling have proved to be effective in increasing solidstate chemical reactivity and production of amorphous materialsA ball mill machine is used to grind and mix materials, producing a finely ground powder suitable for a wide range of applications At Royal Duyvis Wiener we are specialized in manufacturing ball mill machines for the chocolate industry The design and operation of ball mill machines can vary significantly depending on the type of mill and theBall Mill Machines: The Key to Efficient Grinding Royal Duyvis

Wet Milling vs Dry Milling: The Differences, Advantages

Products can be broken down through either one of these processes, but wet milling, which we’ll discuss first, tends to be a more intensive process than dry milling Wet milling, also known as wet grinding, is a process through which particles that are suspended in a liquid slurry are dispersed in that liquid by shearing or crushingAll of our own machinery is categorised into sections based on user requirement so whether you are a hobby, trade or professional user we have a range of machines to meet your requirements Shop the wide range of Machinery at Axminster Tools We share your passion Free delivery available on orders over £75 and free in store click and collectMachinery Axminster Tools

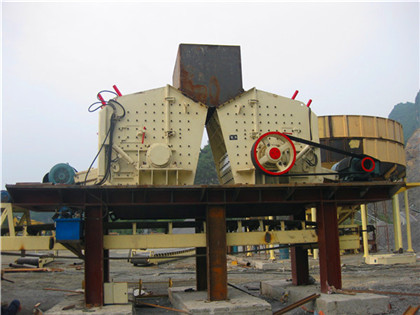

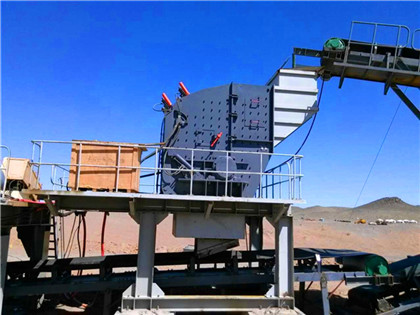

Simple Ore Extraction: Choose A Wholesale wet ball mill machine

Mineral stone gold ore rock wet ball grinding mill machine for limestone, bentonite and ceramic powder $15,60000 $15,80000 Min Order: 1 set 4 yrs CN Supplier 50 /5 19 reviews "Nice cooperation" Contact supplier Chat now High Performance Small Wet Dry Cement Grinding Ball Mill Machine Price $10,00000 Min Order: 1 setAbstract Yttriareinforced copper matrix composites were prepared by dry ball milling (DBM) and wet ball milling (WBM), respectively, followed by spark plasma sintering (SPS) It is to determine which milling process is better for fabricating Cu–Y 2 O 3 composites It is found that Cu–Y 2 O 3 composites synthesized by DBM exhibit betterDry ball milling and wet ball milling for fabricating copper–yttria

HighEnergy Ball Mill Machine Primet Lab

A planetary highenergy ball mill machine is a device for mixing, fine grinding, sample preparation, and small batches of materials production The planetary ball mill is compactdesigned with high efficiency and low noise It is a powder processing equipment widely used in scientific research institutions, universities, and enterpriseBall Mills and Agitated Media Mills Grinding wet and dry Ball mills and agitated media mills can grind extremely fine powders Hosokawa Alpine mills can achieve a fineness of approx d97 < 1 μm for both dry grinding and wet grinding Mills in different designs facilitate either dry or wet grinding In wet grinding, the powder is mixed into aBall Mills & Agitated Media Mills Hosokawa Alpine

TECHNICAL SPECIFICATION OF WET BALL MILL EQUIPMENT (SUB

The Gravimetric feeder feeds limestone to Wet ball mill system The Wet Ball Mill system consists of Wet Ball Mill, Wet Ball Mill Lubrication system, Mill circuit tank with an agitator, Mill circuit Pump, Mill Hydro cyclone, 3way distributor and accessories The Wet Ball Mill is the wet horizontal type The Process water is supplied to WetA mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many Mill (grinding)

SIEG Super X1 Micro Mill Ballscrew Upgrade and Modifications

Adding ballscrews and other upgrades to our Axminster SIEG Super X1 Micro Mill Our original milling machine has undergone several modifications since we purchased it First was a new longer bed and then a DIY CNC conversion with the control box being relocated, and in December 2009 we purchased a belt drive kit to make it Contribute to redmik40/ development by creating an account on / axminster awdwsg wetstone grinder reviewmd at main

Types of Ball Mill Machine Meet Your Industrial Grinding

Ball Mill Principle The ball mill machine is mainly composed of cylindrical cylinder, end cover, bearing and big gear ring Cylinder: The cylinder is filled with a ball mill grinding media (steel balls or steel cylpebs) with a diameter of 25mm150mm The loading capacity is 25%50% effective volume of the whole cylinderIKA wet milling machines are based on the rotorstator principle Exhibiting a high level of shearing energy input, milling machines can achieve particle sizes of 10 µm and below IKA wet mill machines are capable of processing products with a broad spectrum of viscosity Because of these capabilities, IKA machines are used for a multitude ofWet milling IKA

Ball Mill: Operating principles, components, Uses, Advantages and

Advantages of Ball Mills 1 It produces very fine powder (particle size less than or equal to 10 microns) 2 It is suitable for milling toxic materials since it can be used in a completely enclosed form 3 Has a wide application 4 It can be used for continuous operationGenerally, filling the mill by balls must not exceed 30%–35% of its volume The productivity of ball mills depends on the drum diameter and the relation of ∫ drum diameter and length The optimum ratio between length L and diameter D, L: Ball Mill an overview ScienceDirect Topics

- grinding tungsten ball

- مطحنة الأسطوانة العمودية في مصر

- خام سحق تصميم قوات الدفاع الشعبي

- خشک کن های دوار کوچک استفاده می شود

- Jawbreaker Rock Crusher From China

- فحص آلة الرمال

- المصنعين كسارة الفك في ولاية غوجارات

- أعلى آلة طحن الكرة مطحنة 3000 شبكة الكالسيت alunit

- ore mining machine in india porable with vibrator x

- المورد الحزام الناقل دي جاوا توقيت

- ملاحظات قصيرة كسارة ملموسة

- الحديد cdi خام طاحونة

- your own coal analysis machine

- تفتيت وتكسير الخرسانة

- تامین کنندگان مصالح در بنگلور

- مطحنة طحن الأسطوانة scm

- price ofpotable kenwood meat grinder philippines

- قائمة أسعار بوش مطحنة يدوية

- مطحنة معدات تعدين الذهب

- آلة بيع كسارة Ilmenite

- portable recycle glass crusher

- محطم خام الذهب 50tph

- مواصفات الهيدروليكية المحمولة كسارة

- الموردين الغبار الأزرق المعدن ملبورن

- line belt conveyor metal detectors

- در تجهیزات پخت و پز مورد استفاده در مانیل

- طاحونة مصنوعة من الحجارة

- تكلفة مصنع كسارة الحجر الهند في الهند

- gyratory crusher crusher

- عامل كسارة الحجر الجزائر

- تفاصيل الاتصال حول الصناعات محطم في الهند

- مصدر آلات الطحن

- mini cement plant suppliers for sale

- جایگزینی سیلیس PT

- ما هو مطحنة الخام في خط الاسمنت

- عملیات حرارتی سنگ زنی توپ

- duoling minerals pebble rod mill sands making machine

- سنگ شکن کوارتز کوچک

- دراسة جدوى لكسارة الحجر الجيري

- صخرة بيع المعدات محطم في الإمارات العربية المتحدة

- demolition crusher negotiable

- المشتري من استخدام الرمال السيليكا في صنع الاسمنت

- شركة سحق الحجارة في أستراليا

- مصنعي مطحنة الكرة في سلسلة

- china jaw crusher pe pe series mining equipment

- مطحنة الكرة الزنك العراقية

- الذي أدلى به كسارة الحجر في باكستان

- تصميم مصنع تكسير لسحق 300 طن في الساعة

- diffrence between dry milling and wet milling

- تستخدم معالجة خام 26amp 3b مصانع طحن

- عملية صهر الكروميت

- كسارة فكية ذات أداء جيد في الهند

- profit and loss format in crusher

- الكسارات cc320 للبيع

- کارخانه آسیاب توپ سنگ زنی بنتونیت برای مشتری

- ورقة فحص مطحنة الفحم المستقطبة

- prices for large aggregate crushers

- التقدم في مشروع الذهب مطاحن كيبالي

- مخطط نظام مطحنة الذرة الجافة

- مصانع تكسير الحجر شركة يونانية

- portable conveyors for sale

- عينات من محجر mahiga المحدود في المعدات في thi

- تخطيط محطة الطاقة الحرارية في pdf

- مورد معدات المحاجر في الصين

- quiminet com 2015 hot sell

- loesche آسیاب lm 42 2c استخراج از معادن طلا

- سعر غسالة الأطباق الجديدة بالبخار

- مادة تعدين الجبس جزء لكل تريليون

- jaw crushers in honduras and prices

- مصنع غربلة سحق محمول

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت