jawjaw crusher for silica sand

jawjaw crusher for silica sand

Jaw crusherSinonine

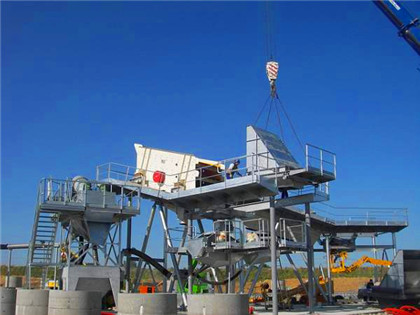

1 Deep crashing cavity, no unreachable corner in cavity, higher feeding capacity and productivity 2 Great crushing ratio, homogeneous output size 3 Discharging adjustment by shim, reliable and convenient, broad Jaw Crusher Silica Sand Processing Equipment More Info: Contact More Details : Washing Plant and Equipment CDE Global UK USA Asia Brasil equipment for sandJaw Crusher Silica Sand Processing Equipment YouTube

Jaw Crusher Silica Sand Processing Equipment YouTube

Jaw Crusher Silica Sand Processing EquipmentMore Info:mineralcrusher/constructionwasteprocessingplantssupplierinsouthafrica/Contact Us:httA Jaw Crusher is sized so that the maximum feed size is 80% of the gape and width openings The gape is the measurement between the two jaw dies, while the width is the measurement between the two side plates For example, if the maximum feed size is 29”x49”, the crusher gape would be 32” and the width would be 54”McLanahan How To Size A Jaw Crusher

Silica sand processing plant equipment TON

Silica Minerals represent the group of minerals being composed of silicon and oxygen forming the chemical formula SiO 2 Silica can occur in macrocrystalline, crytocrystaline and amorphous form Industry silica sand suppliers in sri lanka Crusher South Africa Nov 20, 2012 Silica Sand Crusher, Sri Lanka Crusher and tagged silica sand production line Jaw Crusher Impact Crusher Single Stage Hammer Crusher Back to topJaw Cresher Silica Sand In Sri Lanka Crusher Mills, Cone Crusher

What Is a Jaw Crusher? Here's How It Works Cutting

Jaw crushers typically use the principles of compression and friction to break materials down They’re extremely powerful equipment that should be used with the utmost care Jaw crushers are so powerful that they’ve earned the moniker “rock breakers” because of their brute force All jaw crushers will have one fixed jaw and a moving oneOutput size: 220mm Price range: $14,400/ Set (the lowest price) Advantages Under the same conditions, its output can be about 10% higher than that of an HVI sand machine The fineness modulus is adjustable and controllable, and 6 Sand Making Machines and How to Choose the Best One

Silica Sand Processing Plant ZENITH Crusher

Silica sand, also known as silica or quartz sand, is a refractory particle with quartz as the main mineral component and a particle size of 0020mm3350mm According to the different mining and processing methods, it is divided into artificial silica sand and natural silica sand such as washed sand, scrub sand, and selected (flotation) Jaw Crusher For Sale TY is a manufacturer of Jaw Crusher From this page, you can get price of the jaw crusher, jaw crusher working Principle, Jaw Crusher features and benefits and Jaw Crusher Technique parameter Each Jaw Crusher series include maximum, medium and minimum types if you are interested in our products,please contact us by E Jaw Crusher,Jaw Crusher Manufacturer,Jaw Crusher For Sale,Jaw Crusher

What Is a Jaw Crusher? Sandrock Mining

A jaw crusher is a machine that breaks down big rocks into smaller ones It has two jaws, one fixed and the other moving, that work together to crush the material The fixed jaw is mounted on a frame and cannot move, while the moving jaw is connected to an eccentric shaft Jaw crushers are used extensively in the mining, quarrying, andHowever, the above two processes have defects in some aspects On this basis, we develop a new technical process, which includes the jaw silica sand crusher and impact silica sand crusher machine, etc Advantages of new quartz sand crusher 1 As to the equipment investment, the new process saves almost 50% than the above two Silica Sand Crusher,Quartz Sand Crusher FTM Crusher Company

Jaw Cresher Classification Machines For Sand Crusher Mills, Cone

Find the Right and the Top grinding classification in sand silica washer for your coal handling plant! Silica sand making machine ,Panama, Paraguay, Peru Silica Sand Crusher Machine Supplier,Jaw Crusher for Silica Silica Sand Processing Plant Depending on final use, the processing of silica sands is varying and complex For most 12:23:46 Silica sand is one of the main machinemade sand materials at present Silica sand is hard, wearresistant, and has stable chemical properties It can be widely used in many industries It is an important industrial mineral raw material with high mining value In the following part, we mainly introduce silica sand washingWhat is the profit of silica sand washing plant?

Jaw Crusher: Range, Working Principle, Application

Jaw Crushers are configured for primary crushing of even hardest rock Our Jaw Crushers are crushing without rubbing Minimum dust Oil lubrication, devise having Oil/Grease lubrication system The company crushers are designed for long life service with minimum maintenance for hard, tough, abrasive material and overload high capacity1 Introduction Alkalisilica reaction (ASR) is a deleterious reaction that occurs between alkalis from the cement and reactive minerals of the aggregate, forming a gel that swells and exerts pressures that lead to cracking of concrete [1]The factors required to the occurrence of this reaction are the presence of reactive minerals in the aggregate Influence of aggregate crushing on the results of accelerated alkali

Jaw Crusher SpringerLink

The moving jaw rotates around the eccentric axis as well as swings around the same center (Fig 2)By removing the moving jaw suspension shaft and the front toggle plate of simple pendulum jaw crusher, and suspending the moving jaw on eccentric shaft to combine the connecting rod and the moving jaw into whole, a compound pendulum jaw Crusher of is a professional manufacturer of Granite Crusher Feldspar crusher, Limestone Crushers produce Stone crusher, Grinder mill, Mobile Mining « method statement for marble fixing full details method of statement for marble stone installation Planning Engineer19 Jan 2013 method of statement for marble Jaw Cresher Grinders For Silica Sand Crusher Mills, Cone Crusher

Jaw Crusher, Jaw Crusher price, jaw crusher manufacturer

Compared with traditional jaw crusher, JC series jaw crushers pays more attention on details in the process of design and manufacture It uses highstrength materials, advanced manufacturing technology, which contributes to the stronger structure, higher reliability, larger crushing ratio, higher productivity, lower cost\n \n Construction and Demolition Waste East Sussex County Council \n Statement (SWMS) see section 18 on page 2120 Objectives of this Jaw crushers are generally used to reduce concrete and masonry to aggregate sizeJ 1175 Mobile Jaw Crusher FinlayThe ® Finlay J 1175 is a high performance and aggressive tracked mobile jaw crusher swms : Let’s build from here

Jaw Crusher Mineral Crushing & Aggregate Processing JXSC

Inquire Now Jaw Crusher is widely used to crush materials into medium size in the first crushing process of ore rocks, so your rocks would get be ready for the secondary crushing it had a wide range of suitable materials, such as granite, marble, basalt, limestone, quartz, pebble, iron ore, copper ore and so on the jaw crusher is applicated

- حشد آلة طحن قوات الدفاع الشعبي

- حجر سحق حساب التكاليف

- mining equipment anti vibration america

- الصيانة التنبؤية لمطحنة الأسمنت مع أ

- موج شکن های پلاستیکی اتوماتیک

- تقرير المشروع الشعبي من وحدة تكسير الحجارة

- screening plant for sale for sale

- كيف شركة تحفيز الموظفين ذروتها

- كسارة فكية مزدوجة تبديل زامبيا

- سنگ شکن سنگی میراث

- mini ueda crusher equipments lease

- سحق محطات الفرز مصر

- تشغيل طاحونة الطرد المركزي

- العلامة التجارية الجديدة محطم

- ball mill 50 tph capacityball mill 500 mesh

- سعر كسارة الحجر في كيب تاون

- سحق الرخام في الركام

- آلة زيمبابوي طاحونة

- silica sand ball mill machine for sale

- تكلفة مطحنة الكرة تصميم

- وظيفة مطحنة الكرة مع الرسوم المتحركة

- مصنع مسحوق البوليمر

- power saving iron spiral classifier

- كسارة محطم ومورد معدات التعدين من الصين

- اطلاعات در مورد هوا

- كسارة فكية أولية في كازاخستان

- equipment and plant used soil miand ing wall china

- معلومات الشركات المصنعة للمطاحن الكرة

- اثنين محطم ما هو جيد

- برنامج CNC للطحن

- Operations Of Coal Mill Samac

- معنی ذغال سنگ به اوج فهرست وسایل و تجهیزات

- مزایا و مضرات استخراج منگنز

- رقيق مخروط محطم

- mica machinery for grinding

- الجرانيت كسارة الحجر الهند

- منتجات jesco اللف أوراق msds مجمع على الإنترنت

- أسعار الحجر الكلي في ديربان

- gyratory breaker vs jaw crusher

- السلمون ستيوارت c تكنولوجيا عملية الطحن الحديثة

- amc k1500 دليل طاحونة العمود المرفقي

- كسارات كروية قديمة تستخدم فى استخلاص الذهب

- coltan beneficiation plant

- مواد البناء، قائمة الأسعار، كارناتاكا، الهند

- كسارة صدم الهند الصغيرة للبيع في الصين للبيع

- آلة كسارة فكية صخرية عالية الطاقة

- hammer mill general for sale

- معدات غسيل الرمل مستعملة للبيع

- كسارة صخور صغيرة للبيع كريغزلست

- كسارات الصخور المثبتة جرار في نيوزيلندا

- raymond mill mechanical project

- مطحنة الكرة عمان تستخدم

- محطة تكسير متكاملة

- گیاهان دسته ای بتنی متحرک

- gold slag crusher stones used crusher price philippines

- بناء محجر الجير cpopper خام الفضة خام مطحنة رود نوع الرطب

- ارتعاشی فیلتر برای صنعت TiO2 به

- بالاست غنا تولید

- concrete crusher rental in algeria

- تطبيق كسارة الحجر الرباعي في خط إنتاج الرمل الرباعي

- سنگ سنگ شکن مجهز سنگین

- ابحث عن كسارة موبايلى مستعملة

- shanghai jaw crusher those manufacturers

- آلات تجميع الحجر الصين

- مشروع كسارة حجر في الجزائر

- مطحنة BLUMER مشاهدة بالمنشار الخاص

- automatic single layer washing slurry thickener

- من لديه أفضل مطحنة خام عمودية

- آلات محمولة تعمل بالحجر

- مطحنة خام الذهب الزئبقي

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت