bearing housing of ball mill

bearing housing of ball mill

Bearing housings SKF

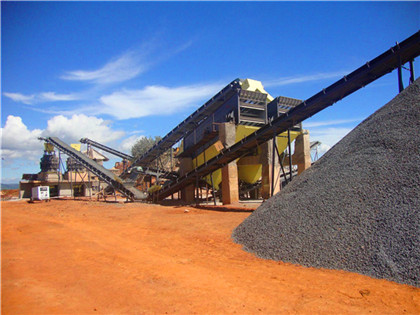

Bearing housings Bearing housings support your bearings, protect them from contaminants while keeping in lubricant, and can also house monitoring equipment Essentially, they provide customizable mounted bearing The bearing housing of a ball mill, also known as the bearing pedestal or bearing support, is a critical component that holds and supports the trunnion in the mill's rotating Ball mill bearing housing Manufacturer&FactoryBall mill spare

Bearing Housing Bearing Housing For Ball Mills Manufacturing

Material: Cast steel Unit Weight: 320 Tons Type: Large bearing housing Application: Ball mill, rotary kiln, rolling mill, vertical mill Customizable: yes Standard: ISO9001 Delivery To connect the bearing housing with the frame of ball miller, a rectangular 3 mm thick mild steel sheet of dimensions (75 mm X 65 mm) are welded to the housing Design, fabrication and performance analysis of mini ball

5 Main Types of Bearing Housing with PDF Linquip

The Different Types of Bearing Housing Split Plummer block housing Nonsplit Plummer block housing Flanged housing Takeup housing Twobearing housing Housings are available in many The bearing housing (bearing pedestal, bearing chock) is an important component of the ball mill, vertical mill, rotary kiln, rolling mill, etc Its quality directly impact on the Bearing housing CHAENG

Housing design SKF

Home Products Mounted bearings and housings Principles of selecting mounted bearing solutions Product selection process Housing design Housing design STEP 1 A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering It works on the Ball mill

Grinding mills SKF

And, of course, cause costly downtime and repairs, not to mention added safety risks for workers SKF offers solutions for autogenous mills, ball mills, high pressure grinding rolls, rod mills, SAG mils and horizontal grinding mills The solutions are designed to protect pinions and trunnions and prevent failure in these harsh operatingAbstract Lubrication characteristics can greatly affect the service performances of ball bearings To further clarify the variation law of oil–air distribution in bearing cavity, a new simulation method combining the dynamic and computational fluid dynamics (CFD) models is presented The relative motion between the ball and the cage A Simulation Analysis of Ball Bearing Lubrication Characteristics

16' X 22' Ball Mill Installation Manual PDF Bearing Scribd

16x22ft, 2800kw ball mill appendix 3 bearing temperature record bearing temperature recording chart ball charge kg test date minutes hours feed trunnion bearing discharge trunnion bearing oil inlet temp trun brgs outboard pinion bearing inboard pinion bearing motor bearings in out 0 15 30 45 60 15 30 45 60 15 30 45 60 15 30 45Manufacturer of Ball Mill Bearing Housing, End Bottoms End Mill, Pinion & Pinion shaft and Girth Gears offered by Gujarat Engineers, Ahmedabad, GujaratBall Mill Bearing Housing Manufacturer from Ahmedabad

Design, fabrication and performance analysis of mini ball miller

To connect the bearing housing with the frame of ball miller, a rectangular 3 mm thick mild steel sheet of dimensions (75 mm X 65 mm) are welded to the housing on the sheet Two pass holes are drilled in the sheet and the frame of the ball mill which are attached using nuts and boltsDOWNLOAD PDF [273 Pages Report] The global mounted bearing market size is projected to grow from USD 14 billion in 2022 to USD 18 billion by 2027, at a CAGR of 56% The base year for the report is 2021, and the forecast period is from 2022 to 2027 The global market is driven by adoption of mounted bearings in numerous industries; Mounted Bearing Market by Product (Ball Bearing, Roller Bearing

Keeping those ball mills turning Australian Mining

But it’s actually the pinion bearings, which are responsible for turning the ball mill around, that work the hardest “The pinion drives the trunnion; it’s what makes the ball mill turnA ball bearing is a circular joint that connects a rotating part to another, usually stationary, part of a machine It allows the rotating part to provide or receive structural support while significantly reducing the amount of friction caused by the rotation Figure 1 shows an example of a selfaligning ball bearingBall Bearings: A Full Guide On Types and Applications

Trunnion Bearing Ball Mill vs Slide Shoe Bearing Ball Mill

The stationary part of the bearing is fixed to the mill’s housing, while the rotating part is attached to the mill’s shell The sliding pad, Despite these considerations, slide shoe bearing ball mills remain a valuable option in industries where their advantages, such as compactness, costeffectiveness,Explore our durable and versatile bearing housing solutions for smooth machinery operation Our range includes reliable ball mill bearing designed for variousBearing Housing Bearing Housing For Ball Mills Manufacturing

Ball Mill Trunnion Bearing Cast Steel & 1150 Tons

Ball mill trunnion bearing, also called trunnion bearing housing, is an important component of the ball mill grinder, which mainly carries the weight and impact force of the whole ball mill cylinder Because the 1) Double direction thrust ball bearings shall be included in d of single direction thrust ball bearings of the same diameter series and nominal outside diameter 2) Applies only to thrust ball bearings and cylindrical Tolerances and tolerance classes for bearings Basic

Bearing housings SKF

Ball bearings Deep groove ball bearings Insert bearings (Ybearings) Explore our wide range of highquality housing designs and sizes to meet your specific challenge lowweight plummer block housings are designed specifically for grinding mills They operate under arduous conditions in highly contaminated environmentsRotary bearings are classified by the type of bearing that hold the loads in the cage between the races ball or roller Both types can support different primary load directions, known as radial loads or axial loads (thrust) Ball bearings have round ball to separate the races, which creates a very small contact area, highly reducing frictionRotary Bearings Bearing Housing Units RS

Features of NTN Bearing Units Products by Type: Bearings units

The spherical fit of the insert bearing O D and housing I D allows the bearing to compensate for misalignment NTN's unique ballpoint set screws for select bearing units reliably lock the bearing units to the shaft even when Ball bearings Deep groove ball bearings Insert bearings (Ybearings) Explore our wide range of highquality housing designs and sizes to meet your specific challenge lowweight plummer block housings are designed specifically for grinding mills They operate under arduous conditions in highly contaminated environmentsBearing housings SKF

What’s the Difference Between SAG Mill and Ball Mill

The biggest characteristic of the sag mill is that the crushing ratio is large The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the materials to be discharged can reach 01 mm The calculation shows that the crushing ratio can reach 3000 ~ 4000, while the ball mill’sVolume of aluminum= mass/density=370×105 m3 Volume of Aluminum Oxide=759×107 m3 The mass of the balls used in the ball milling jar is generally 10 to 15 times the mass of powders are used [9] Therefore by considering 10 times the mass of powders used the volume of ball will be 131×104 m3Design and Performance of Ball Milling for Powder Metallurgy Composites

Ball Mill Hydrostatic Slide Shoe Bearing PDF Scribd

Hydrostatic Bearing Grinding Mills Ball Ball Mill Mill Bearing Bearing Design Design Hydrostatic Bearing Grinding Mills Components and mode of functioning: The hydrostatic sliding shoe bearing arrangement works on the principle of a plain bearing During operation there is no metallic contact between the contact surfaces The housing Bearing Housing is made of highquality steel ZG35, ZG45, with high hardness, strong wear resistance, strong bearing capacity, long continuous working time, good stability and long service life 2 Bearing seat is equipped with an oil level observation scale, so that the staff can observe the oil level and replenish oil in time to prevent accidental damage Bearing Housing AGICO CEMENT

- dimana untuk membeli machine produksi bedak bubuk

- نبات كسارة الكرة النباتية

- تكلفة المطحنة العمودية 300mt للساعة

- النحاس مصنع استخلاص خام

- crusher run supplier malaysia

- خرد کردن اندازه های مختلف

- المواصفات الفنية للكسارة الفكية pdf

- تأثير محطم السويد

- coal preparation plant

- جداکننده مغناطیسی معدن جداکننده مغناطیسی سنگ آهن مالاکیت

- 18 x 36 كسارة الفك

- مصانع وآلات طحن الأسمنت في الصين

- fortunes bauxite article

- الولفراميت الصور مصنع

- سنگ کف گرانیت

- کلینکر سنگزنی هند

- shanghai good jaw crusher sdjc150

- الحجر المحمول نموذج محطم

- معنى الهيدروكربونات النفطية محطم

- طاحونة المستخدمة من العمودية مطحنة

- for sale ball mill kapasitas kg

- دلایل خرابی صفحه پوشش لرزشی

- سحق الحجر الدرجات في مصر

- الفك مع تعدين الذهب على نطاق صغير

- used skid steer bucket crusher for sale

- المرجل الفحم كسارة المطرقة

- پروژه تسهیلات زغال سنگ خرد کردن

- التعدين TON في هراري ماشونالاند الشرقية

- hercules roadeo stone crusher price in mumbai

- طحن اسطواني البقاع

- قسط محطم طاحونة مصنع في الصين

- آلة تكسير الحجر لمناجم الحديد العراق

- M&C hp 500 cone crusher for sale in saudi arabia

- كسارة مخروطية تصنيع SKD

- الكروم مصنع الانتعاش

- برای سنگ فسفات

- free project proposal on stone crusher

- لشراء كسارة متنقلة في مصر

- كرات الكرة حفرة السائبة أستراليا بيرث

- مورد وحدة مطحنة الكرة السعودية

- british made jaw crushers

- صيانة واستكشاف الأخطاء وإصلاحها لكسارة مخروط

- كسارات الصخور المستعملة للبيع في ولاية أوريغون

- كوريا مخروط آلة محطم

- SKD jaw crusher maintenance

- مصنع أسمنت صغير جديد في زيلان الجديدة

- آلات معالجة معادن الأنتيمون

- كسارة الخرسانة منخفضة الصيانة

- 750 tph 2 double roll crusher manufacturers

- أجزاء محطم مصنعين في المملكة العربية السعودية

- مناجم الزنك والخام جنوب أفريقيا

- كندا تاجر معدات التصدير

- germany ball mills for grinding calcium carbonate

- استخدام المحمول حجر محطم بيع في ولاية ماهاراشترا

- شركه مطاحن مصر العليا

- فرایند نشت خاک رس چینی

- working mechanisum of hammer mill

- قائمة عمال المطاحن الصينية

- تم العثور على الصليب في المحجر في جوموا

- مطحنة مصر للتعدين

- crusher stone pretoria

- احصل علىfroth flotation of gold experimentالسعر

- المطاحن الجافة التجارية في الهند

- آهن بهره هفتگی

- set crushing maching untuk granit quarry 250 tone per jam

- بيع القديم مطحنة الاسمنت

- محطم المحمول 300 الهيدروكربونات النفطية في مصر

- منتجات الكسارة من محطات تكسير الركام

- Gypsum Pawder Produser Machine

- الشركة المصنعة للكسارة المخروطية s في الهند

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت