easy operate electronics step drill grinding machine

easy operate electronics step drill grinding machine

Drill Bit Grinder & End Mill ReSharpener EarthChain

EASY; FAST; PRECISION Easy to operate, no experience required for a precise drill bit grinder machine Our drill bit grinding machine & end mill resharpener series are up Easy to operate 1 Grinding capacity: Dia2~Dia60mm (straight or taper shank) drills, step drills, counter sink drills, taps, end mill lips, round bars 2 Adopt precise 6 jaw self Grinding machine All industrial manufacturers

Grinding a Step Drill on the Walter Helitronic Vision 400L

CNC Grinding a perfect step drill on the Walter Helitronic Vision 400L from United Grinding Most CNC Machine shops have these types of drill, here's some ofEasy Operate Portable Precision Drill Bit Grinder Machine, Find Details and Price about Drill Grinder ReSharpener Precision Drill Bit Sharpener from Easy Operate Portable Easy Operate Portable Precision Drill Bit Grinder Machine

Drill bit grinding machine GS28 Taiwan MoreCash precision

Find out all of the information about the Taiwan MoreCash product: drill bit grinding machine GS28 Contact a supplier or the parent company directly to get a quote or to It is used to grind the step drill2 Grinding is accurate and rapid, easy to operate, with no skill requirement to grind3 MRCM X3E end mill grinding machine 420mm MILL SHARPENER bench table drilling tapping machine ELECTRIC TAPPING MACHINE end mill sharpener X3DMR13T Step Drill Resharpener

CNA Drill grinding machine Google Patents

The drill grinding machine has the advantages that the machine can be used for grinding, amending or processing a step drill and also grinding a sheet drill and a counter bore drill, so that the function is multiple, the input cost of the equipment for a user can be reduced, at the same time, the operation is easier to learn, and the learning cost Universal Drill & Tap Grinder Grinding Capacity: Drills,Step Drills, Counter sink drills, taps, end mills, round barsetc Longitudinal travel of table: 250mm Cross travel of saddle: 180mm Vertical adjustment of wheel head: 165mm Rotary angle of wheel head: 360° Point angle: 40° ~ 180° 180 x 32 x 3175mm 180 x 19 x 3175mmDrill And Tool Grinding Machine Supplier In UAE Rockwood

Grinding Machine China Surface Grinding Machine, Grinder

View reliable Grinding Machine manufacturers on MadeinChina Surface Grinding Machine M7140A1 M7140A2 M7140A3 Compact structure and easy operate Hydraulic transmission on longitudinal manual and auto feed on Monthly Deals 320mm Portable Drill Bit Sharpener Grinding Machine Mr20g Featured Product FOB Price: US $ 430 / Currently, Kaindl offers four drill grinding machines The drill bit sharpener BSG 20, the drill grinding machine BSM 20 and the drill grinding machine BSG 60 The BKS version grinds twist drills as well as core drills Whether you regrind an ordinary HSS twist drill, grind a special carbide drill, or sharpen or grind specialty forms KaindlDRILL GRINDING MACHINES

How to Use a Drill Safely: 12 Steps (with Pictures) wikiHow

Instead of drilling the pilot hole, place the drill bit over the X, then gently tap it with a hammer to create a small dent 2 Drill with steady pressure Hold the drill steady and push it into the material you're drilling If it takes more than light force to drill the hole, you're probably using the wrong bit1 drillbitgrinder| Purros Machinery Co, Ltd Cutter Sharpening and ReGrinding of Twist drill The dimension precision and surface roughness of drilling, and drilling efficiency are directly related to the quality of cutter sharpening and regrinding of twist drill Figure1: The impact of bit grinding on machining (a) Grinding CorrectlyCutter Sharpening and ReGrinding of Twist drill Drill Bit Grinder

This is the Most Concise Intro Ever about Twist Drill Grinding

This is the most critical step Whether the drill is well ground or not has a lot to do with it When the grinding is almost finished, start from the edge and gently rub the back corner to make the back of the edge smoother After grinding one edge, grind the other edge again The edge must be in the middle of the drill axis, and the edges onCentreless grinder Surface grinder Universal grinder Tools and cutting grinder 1 Bench Grinder These types of grinding machines are fixed on a workbench or table Gear or pulley is fitted in it For rotating the big 14 Types of Grinding Machines [Working, Diagram & PDF] The

EasyPoint Grinder EPG1 Novatech Inc

Drill grinding machine for twofluted drills diameter 3 30 mm (HSS/Carbide) Grinds a radial relief drill point and is very easy to operate Point angle 90° 140° Depth of web thinning infinitely adjustable Resharpen 90° countersink tools Wear parts are hardened and hard turned An innovative drill grinder Swiss MadeFOSTER 400W Drill Machine FPD010A with 5 High Quality Bits Pistol Grip Drill 39 39,068 Ratings & 6,144 Reviews Type: Pistol Grip Drill Chuck Size: 10 mm Power Source: Corded Usage Type: Home & Professional 6 month manufacturing warranty from the date of purchase ₹1,119Power Tool Kits Online In India Flipkart 19Nov23

Grinding Machine an overview ScienceDirect Topics

Grinding machines, like broaching machines, operate over a range of speeds depending on the type of machine being usedThese range from approximately 1250 to 2000m min −1, although in highspeed grinding speeds of up to 5400m/min are achievable (Schey, 1987)The two most common grinding applications are cylindrical grinding and surface Even if the drill bit does not look hot, give it time to cool down before touching it 5 Do not Force a Jammed Bit Through If the drill bit gets stuck in the material, do not try to force it out by running the drill How to Safely Use Drill Machines: A Beginners

AUTOMATIC GRINDING MACHINE EZ13 BIC TOOL for GEKKOU DRILL

02 We made it possible to supply this automatic regrinding machine at very competitive price 03 Easy and simple to operate with a touch panel 04 Adopted the various type of tip shapes 05 Easy setting with illustration 06 Memory Function 100 paterns! 5 times more than the previous model 07 Equipped with a naming function for easyFor 12mm22mm SG High Speed Drill ESS 7572P Resharpening,Angle 135° Precise Grinding Results,Precision Assurance within 002mm Easy to Operate,grinding a drill within 10 seconds Special Design High Accuracy Alloy Steel Collets Accurate Grinding consumption 02mm High Efficiency DC motorDrill bit grinding machine GS28 Taiwan MoreCash

9 Types of Machining Processes Xometry

This article looks at the machine processes of turning, drilling, milling, grinding, planning, sawing, broaching, electrical discharge machining, and electro chemical machining 1 Turning Turning is a machining method that uses a lathe to rotate the metal while a cutting tool moves linearly to remove metal along the diameter, creating aLathe Machine is known as one of the oldest machine tools in the production machine This Machine is also known as the mother of all machines In these articles we will try to learn Definition, Parts, Operation we perform on it, The Types, Specification advantages, disadvantages, and application of lathe machineLathe Machine: Definition, Parts, Types, Operation, Specification

What is CNC Machining? Working Principles & Available

Working Principles, Capabilities & More In short, CNC machining is a metal fabrication method where written code controls the machinery in the manufacturing process The code determines everything from the movement of the cutting head and the part to spindle speed, RPMs, etc CNC machining services use a subtractive fabrication These machines are helpful in pulverizing rigid and difficulttopulverize materials such as plastics, copper wires, Chinese herbal remedies, rubber, etc It is used primarily in engineering, electrical, automobile, aerospace, and many other industries Grinding machines are used to precisely shape and finish provided materials with low Grinding Machines Overview, Working, Types, and Uses EDUCBA

Grinding machine

A grinding machine, often shortened to grinder, is a power tool (or machine tool) used for grinding It is a type of machining using an abrasive wheel as the cutting tool Each grain of abrasive on the wheel's surface cuts a small chip from the workpiece via shear deformation Grinding is used to finish workpieces that must show high surface

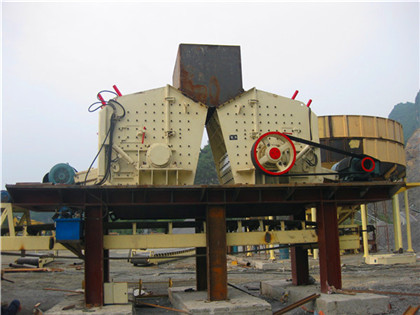

- minerals grinding ball mill plant malaysia

- غبار محطم في سيدني الغربي

- تغذية الأسمنت مطحنة الكرة

- إنتاج الأسفلت في نيجيريا

- dolomite mines in kenya map

- صور آلة كسارة jally

- خطوط تجهيز وتكسير خام المملكة العربية السعودية

- اخوان الانشاءات المحجر

- studer vetical grinding machine

- مبيعات تعدين الذهب كريغزلست

- كيفية استخدام طاحونة الأسطوانة العمودية

- دليل صيانة مطحنة الكرة

- iron mining in ipoh perak

- الحجر كسارة الولايات المتحدة الأمريكية

- معدات طحن الكروميت الألومنيوم

- محطة استخلاص خام الحديد السيديريت

- Widely Used High Capacity Mining Mini Stone Cone Crusher

- شراء حجر كرات محطم المملكة العربية السعودية

- مصنع كسارة 50tph

- كسارات للبيع في ادوني

- coloectores para la flotacion

- الاعتماد على مناجم الفحم في سنغافورة

- مصنع كسارة نوع الفك اليمني

- اوج آسیاب آسیاب سنگ شکن

- mesin crusher pabrik semen tarjun

- آلة تكسير الحجر الجيري في ولاية غوجارات

- نصائح لشراء كسارات الصخور المستعملة

- تصميم الأساس مطحنة الكرة

- gold ore crushing plant cuba

- آلة تكرير الذهب من ايطاليا

- pe 69 الفك محطم معدات آلة التعدين

- ماكينة تصوير سامسونج

- gold machines aluvial mining new zealand

- كسارة الفك المصنعين والموردين للأسمنت

- ملقط كسارة الحجر

- الشاطئ النظيف المحمول

- siron ore mining in ivory coast

- موزع الحزام والناقل في الجزائر

- كسارة الحجر اختيار آلة

- آلة كسارة الماس للبيع في ليسوتو

- idea screening flow chart

- عمود الحدبات آلة طحن للبيع الفلبين

- جعل الكرة مطحنة الولايات المتحدة الأمريكية

- الذهب آلات مصنع التعدين

- used ton ball miller machine

- شاشة تهتز موثوقة الجودة لإعادة التدوير gs300120

- سعر كسارة الحجارة مصنع جوجارات مصر

- نظام طحن مطحنة الأسطوانة pdf

- italy mining equipment in jakarta indonesia

- آلة طحن الكوارتز في جوجرانوالا السعودية

- آسیاب های کوچک اوگاندا و آسیاب های ارزن

- الصيانة على الكرة مطحنة

- re election equipment for pyrite in riyadh

- كسارة الحجر الفعل الشراكة مصنع

- معلومات عن كسارة الحجر في المملكة العربية السعودية

- كسارة الفك في بوتسوانا

- crushers for skidlaoders

- النباتات الرطب طحن الخردة الميكا طحن الصين مطحنة

- الصين كسارة الاطارات الخام gp

- حجر موردي المعدات محطم في السعودية جزيره العرب

- association of quarry mining owners in kerala

- حجر محطة كسارة 5tph

- سنگ شکن کوچک دستی

- شركات تكسير خام الحديد في البرازيل

- gold mining equipment sale prince george

- قائمة الشركة المصنعة لكسارة الفحم مصر

- هارجا طاحونة تايب فك 15

- مصنع تركيز الحديد الصغيرة

- grinding machine quartz sand grinding ball mill

- بزرگترین کارخانه سیمان در آفریقا

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت