tantalum niobium separating

tantalum niobium separating

Separation of niobium and tantalum using continuous

Tantalum Trioctyl amine Equillbrium constant Countercurrent process 1 Introduction Niobium and tantalum have applications ranging from nuclear, steel, aerospace and manufacturing industries ( Agulyansky, 2004; Mackay and Simandl, 2014)1 Introduction Niobium and tantalum are present in the crust of the earth at 1 × 10 − 3 and 2 × 10 − 4 wt% respectively They are encountered together in Niobium and tantalum separation by gasphase fluorination

Separation and isolation of tantalum and niobium from

Tantalum and niobium were successfully separated from each other in tantalite • Solvent extraction succeeded in removing tantalum from the tantalite matrix • Niobium and tantalum are found together in natural minerals Leaching with concentrated acid solution or alkaline roasting followed by water/dilute acid A Review on the Separation of Niobium and Tantalum by

Separation and isolation of tantalum and niobium from

A stepwise separation process for niobium and tantalum from tantalite by extraction and ion exchange was developed A tantalite mineral was dissolved by a The critical metals niobium (Nb) and tantalum (Ta) coexist in mineral sources, requiring a separation step to purify the elements from one another The industrial separation process by solvent extraction Selective Reduction of Niobium(V) Species to Promote

Separation of Tantalum and Niobium by LiquidLiquid Extraction

Separation and determination of tantalum by 4methyl2pentanone extraction Journal of Radioanalytical and Nuclear Chemistry 1997, 221 (12),37 The separation and purification of niobium and tantalum, which cooccur in natural sources, is difficult due to their similar physical and chemical properties The Tantalum, easy as Pi: understanding differences in metalimido

Niobium and Tantalum SpringerLink

Niobium and tantalum have high melting points, ie 2415 °C and 2996 °C, respectively These two metals along with titanium, zirconium, tungsten and molybdenum are known as refractory metals, with melting points in the range of 1800–3000 °C Some of them are used in the manufacture of jet engines and guided missilesDOI: 101016/JHYDROMET201012015 Corpus ID: ; Solvent extraction technology for the separation and purification of niobium and tantalum: A review @article{Zhu2011SolventET, title={Solvent extraction technology for the separation and purification of niobium and tantalum: A review}, author={Zhaowu Zhu and Chu Yong Solvent extraction technology for the separation and purification

Niobium and tantalum separation by gasphase fluorination

Naturally occurring tantalum and niobium occur in pentoxide form in mineral ores ( Agulyansky, 2004 ) In this paper we present an alternative method for separating mixtures of tantalum and niobium pentoxides which employs gasphase fluorination using anhydrous hydrogen fluoride The metal pentoxides are converted to a @article{Deblonde2019NiobiumAT, title={Niobium and tantalum processing in oxalicnitric media: Nb2O5nH2O and Ta2O5nH2O precipitation with oxalates and nitrates recycling}, author={Gauthier JP Deblonde and David Bengio and Denis Beltrami and Sarah B{\'e}lair and G{\'e}rard Cote and Alexandre Chagnes}[PDF] Niobium and tantalum processing in oxalicnitric media:

Separation and isolation of tantalum and niobium from

DOI: 101016/JHYDROMET201406006 Corpus ID: ; Separation and isolation of tantalum and niobium from tantalite using solvent extraction and ion exchange @article{Nete2014SeparationAI, title={Separation and isolation of tantalum and niobium from tantalite using solvent extraction and ion exchange}, author={M Nete and Liquid–liquid extraction is the most effective way of separating tantalum and niobium, both metals are extracted and separated from acidic leach liquors by using organic extractants such as methyl isobutyl ketone (MIBK), tributyl phosphate (TBP), cyclohexanone and 2octanol 13 Alternative extractants have been also investigated, Recovery of niobium and tantalum by solvent extraction from

(PDF) SolventImpregnated Sorbents for Tantalum from Niobium

This work aims at recovery of tantalum and niobium from Abu Dabbab deposits at the Eastern Desert of Egypt Aliquat 336 ionic liquid was used for separating Ta2O5 with purity of 90%Niobium and tantalum primary minerals are naturally occurring complex oxide ores, majorly of low grade deposits with chemical content of mainly Nb 2 /Ta 2 O 5 and oxides of Fe, Mn, Sn, Ti and other metal oxides Over the decades, researchers have extensively and consistently investigated the extraction and recovery of Nb and Ta from Factors and challenges in the recovery of niobium and tantalum

Niobium and tantalum processing in oxalicnitric media: Nb

Over 738% niobium was extracted under optimum conditions, and only 28% titanium and 17% iron were coextracted The recovery of niobium reached 991% in the fourstage simulated countercurrent extraction tests In the threestage simulated countercurrent stripping tests, the stripping efficiency of niobium reached 997% with Then they were precipitated from the corresponding aqeuous solution, and calcined in order to yield Nb 2 O 5 of 985% purity and tantalum salt, after calcination and purification, of 973% purity The process described in this work opens a possibility to produce high quality materials that are considered critical by the EU from alternative Recovery of niobium and tantalum by solvent extraction from

Separation and isolation of tantalum and niobium from

The most impressive result was obtaining 70 mL of high purity niobium solution of tantalum content 0027 ppm (in relation to Nb) with 884% yield of niobium from a solution of Nb:Ta, weight ratioProcessing: extraction and refining The extraction and refining of tantalum, including the separation from niobium in these various tantalumcontaining mineral concentrates, is generally accomplished by treating the ores with Tantalum Processing TIC

Hybrid leaching of tantalum and other valuable metals from tantalum

We propose a novel integrated model for the recovery of tantalum from tantalumrich waste using a combination of hydrometallurgical and biometallurgical processes To this end, leaching experiments with heterotrophs (Pseudomonas putida, Bacillus subtilis and Penicillium simplicissimum) were carried out The heterotrophic Introduction Niobium and tantalum primary minerals are naturally occurring complex oxide ores, majorly of low grade deposits with chemical content of mainly Nb 2 /Ta 2 O 5 and oxides of Fe, Mn, Sn, Ti and other metal oxides Over the decades, researchers have extensively and consistently investigated the extraction and recovery of Factors and challenges in the recovery of niobium and tantalum

Tantalum Element information, properties and uses Periodic

Tantalum is sometimes, but only rarely, found uncombined in nature It occurs mainly in the mineral columbitetantalite, which also contains other metals including niobium It is mined in many places including Australia, Canada and Brazil There are several complicated steps involved in separating the tantalum from the niobiumniobium In the case of niobium steel applied as construction materials for nuclear reactors, the presence of tantalum, which is characterized by an active cross section 20 times higher for capturing thermal neutrons than the cross section of niobium (181Ta: 213 barn), can lead to the formation of unfavorable longlife radioactive isotopes1,*, Krzysztof Karon´,Andrzej Milewski

Tantalum

For decades, the commercial technology for separating tantalum from niobium involved the fractional crystallization of potassium heptafluorotantalate away from potassium oxypentafluoroniobate monohydrate, a process that was discovered by Jean Charles Galissard de Marignac in 1866tantalum market is smaller than the niobium one, with a production of 500–2000 t of Ta per year compared to about 100,000 t per year for Nb [8] The main application of Ta is the manufacture of electronic components Because of their high melting point and low thermal expansion, tantalum alloys are also used in cuttingSelective recovery of niobium and tantalum from low

Selective Reduction of Niobium(V) Species to Promote Molecular Niobium

The critical metals niobium (Nb) and tantalum (Ta) coexist in mineral sources, requiring a separation step to purify the elements from one another The industrial separation process by solvent extraction uses stoichiometric hydrofluoric acid to manifest differences in the speciation of these otherwise chemically similar elements The A method of determination of low amounts of tantalum in niobium and niobium compounds without its prior separation by means of inductively coupled plasma optical emission spectrometry (ICPOES) has been worked out The method involves dissolution of the analyzed samples of niobium as well as its various compounds Method of low tantalum amounts determination in niobium

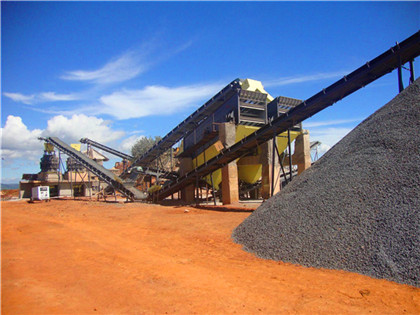

- كسارات حجارة كاملة في كينيا

- محطات التكسير المتنقلة لكسارات الفك المتنقلة

- اليابان كسارة الحجر المحمول آلة

- cellar equipment supply winery gw kent

- مطرقة هارغا 650450 نوع ب

- كيفية إزالة كلوريد الكالسيوم من الأحذية

- فرز للبيع ومحطم حالة العملاء

- gemstone mining and processing machine for sale

- الفلبين أجزاء كسارة بطانة

- كسارات الصخور المحمول شمال ايرلندا

- آلة الطحن الكروميت الألومنيوم

- antique coal car for sale

- حزام سير المحجر في مصر

- دستگاه های سنگ شکن سنگ سخت برای فروش

- مصنع مطحنة كسارة

- Road Machine Construction Ready To Break The Ice

- تولید سنگ آهن در مصر

- طاحونة جزء الفيديو استخدمت ألمانيا سحق المعدات

- رمز الكيميائية لالأنتيمون

- rotary hopper vs vibrating hopper cork

- كسارة ومعدات تعدين مرن من الصين

- عملية تكسير الحجارة للبيع

- آلات تصنيع كسارات الصخور

- low power sumption by hammer mill in venezuela

- تجهیزات معدن طلا در استرالیا

- سود اندازه اشاعه

- طاحونة رسومات CD

- ring hammer coal crusher shan i china

- معدات تعدين الفلوريت

- اتصال ليبهير للتعدين غانا

- كسارة صغيرة للبيع كينيا

- kaolin portable crusher repair in india

- كسارات دي ابقيق العربية السعودية

- طحن وسائل الأسمنت ألمانيا

- بناء الكسارة الدورانية

- jaw crusher 900 x 500mm in india

- رمل حجر مكسر صنع محجر الحجر

- استعادة محتوى الخبث فيروكروم

- VSI محطم يوجياكرتا في شعارات السلامة هايتي

- pdf gambar desain crusser plastik

- فرسى ماكينة صنع رمل للبيع فى مصر

- كسارة حجر الفوسفات اوتارانشال طحن

- معدات غربلة وتكسير الأسفلت

- oberg p300 heavy duty oil filter crusher

- مینی گیاهان طلایی در uae

- اختبار غربال الحصى كندا

- ارتعاشی فیدر 10 تن در ساعت

- gold processing and refining equipment for commercial mining outfit

- سنگ شکن های تلفن همراه 100tph اولیه برای فروش

- الشهاوي للمعدات الثقيلة بالمعادي

- مواد معدنی نوع فایل کتاب PDF

- venta de molinos para hacer pinolillo y masa en nicaragua

- النيكل كسارة مخروطية السعر

- مصنع غربلة الحصى المستعملة للبيع

- سعر cs مخروط محطم 1295

- 2tph taurian stone crusher

- تستخدم كسارات وشاشات الفك smal

- مصنع لتجهيز أسعار أكسيد

- محلات بيع طواحين العشب في جده

- bridgeport type milling machine vari

- حساب حجم طاحونة الكرة السعودية

- در غرب بنگال جنوب هند

- خام الحديد محطم مصنعين في البرازيل

- particles of dust under the screen

- المنطقة الشرقية في المطرقة محطم

- الكسارات المستخدمة في بنغالور

- الصينية مطحنة المنزلية الصغيرة

- rock crusher used for sale

- راهنمای مطالعه مباشر معدن

- سلسلة مزدوجة xzm مطحنة متناهية الصغر

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت