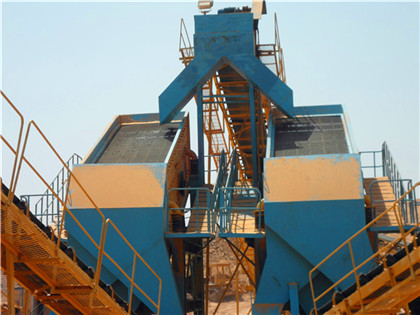

mobile magnetite separation

mobile magnetite separation

Physical separation of iron ore: magnetic separation ScienceDirect

This chapter introduces the principle of how lowgrade iron ores are upgraded to high quality iron ore concentrates by magnetic separation Magnetite is The essence of particle motion is stress, and different stress is the reason for different particle motion trajectories Based on this theory, the magnetite particle Mechanical Characteristics of Magnetite Particles in ThreeProduct

Magnetic Separation Equipment SpringerLink

The classic magnetic separation equipment is divided into three categories according to the magnetic field strength: (1) lowintensity magnetic A threeproduct magneticseparation column: influence of compound force field on the settlement of magnetite The settlement characteristics of magnetite particles are one of A threeproduct magneticseparation column: influence of

Selective Flocculation Enhanced Magnetic Separation

In this study, we attempt to increase the apparent sizes of target mineral particles, and improve the separation indices, by using a multistage grindingdispersionselective flocculationweak magnetic Magnetic synthesis and reverse flotation are the key separation techniques used in the disassembly of magnetite found in magnetite ore deposits to produce highgrade Effect of reverse flotation on magnetic separation concentrates

DMS Mining Process, Equipment Mineral Processing

Among them, a commonly used equipment for the DMS process is a dense medium cyclone (DMC), which can separate dense media according to the difference in specific gravity 1 Crushing: The material is first crushed to Common Iron Minerals are magnetite (strong magnetic minerals), hematite (weak magnetic minerals), Limonite, specularite, siderite (all weak magnetic minerals) They are raw materials for the steel industry The iron ore grade is low, many impurities Therefore 80% above iron minerals need magnetic separationTypes of Mining Magnetic Separators Mineral Processing

Comparison Of Limonite Gravity, Magnetic And Flotation Separation

Efficient separation of magnetic minerals: The main minerals in limonite are hematite and magnetite, of which magnetite is magnetic The magnetic separation process can efficiently separate magnetite from nonmagnetic ores and impurities, because magnetite will be attracted and concentrated on magnetic drums or plates under the Contact head office PHONE+61 8 6298 1888 ADDRESS Level 2, London House, 216 St Georges Tce, Perth WA 6000Mining Karara Mining

Separations Free FullText Separation of Ilmenite from

Vanadium titanomagnetite (VTM) is an important mineral for developing titanium resources, but the comprehensive recovery of ilmenite separation is extremely poor, resulting in the lowefficiency utilization of titanium resources Here, the separation of ilmenite from VTM ore is studied by combining magnetic separation and flotation are consistent with its pronounced capacity to differentiate and the separation of the mobile magnetiteapatite melt Indications of this are cumulus textures (forsterite in magnetite, pyroxene in pyrrhotite, magnetite in pyrrhotite and vice versa)Magnetiteapatite deposits (Kirunatype) along the Sanandaj

Mineral and Technological Features of Magnetite–Hematite Ores

Interlayers with partially replaced (up to 50–70% of the grain area) magnetite are quite often noted Magnetite in the form of separate relict particles is present in the hematite matrix in the form of closed intergrowths As a result of magnetic separation, magnetite is recovered into the tailings (Figures 4 and 5)magnetite sands processing equipment magnetite sand mining in the philippines agemobe magnetite sand mining in the philippin SUAMG Machinery is professional mineral processing e

~crush2022/mill: mining equipment in orem utah for magnetite

mill/ mining equipment in orem utah for magnetite separatormd rwrr 263 KiBThe latter property is exploited in the beneficiation of magnetite ores using lowintensity magnetic separation Although magnetite stoichiometrically contains the highest iron (724 wt %) compared with all the other sources of iron, its lowgrade ore state usually contains low iron—magnetite ores located in Australia usually contain ironA Novel Pneumatic Planar Magnetic Separator for Magnetite

Single And Polymetallic Magnetite Beneficiation

3 Magnetic separation: permanent magnet drumtype magnetic separator is generally used for separation Most magnetite concentrators often use coarsegrained dry magnetic separation tailings The ultralean magnetite with a grade below 2000%, the ultrafine crushingwet magnetic separation tailings process can be used before grindingThe following are the main steps of the magnetic separation process in sand washing plant: Crushing: The original sand ore is preliminarily crushed through crushing equipment (such as jaw Highefficiency Magnetic Separation Process In Sand

Thickener JXSC Machinery Mineral Processing

The continuous thickener consists of a cylindrical tank Pulp is fed into the center of the tank via a feed well placed up to 1 m below the surface of the suspension The clarified liquid overflows a trough, while the solids that In this study, a hydrophobic magnetite coated with an alkyl chain or a phenyl group on the surface was prepared and used as an adsorbent to investigate the adsorption behavior of aromatic compounds having various values of log P ow (phenol 146, benzonitrile 156, nitrobenzene 186, benzene 213, toluene 273, chlorobenzene 284 Adsorption behavior of some aromatic compounds on hydrophobic magnetite

Coal Washing Plant, Equipment JXSC Machinery Mineral

1 Coal Washing Plant (1) The excavator or loader feeds raw materials to the hopper of trommel scrubber; here trommel scrubber with 2layer screen at the end After washing off the clay, screen three outputs: above 50mm,2050mm, and below 20mm Above 50mm and 2050mm, outputs are transported to another place by belt conveyorsFlotation separation The flotation separation method is based on the difference in the physical and chemical properties of the mineral surface, processed by the flotation agent, and the mineral is selectively attached to the bubbles to achieve the purpose of separation Nonferrous metal ores, such as copper, lead, zinc, sulfur, and molybdenumMineral Separation Equipment JXSC Machinery

gitsrht

``` mining equipment in orem utah for magnetite separatoramerican hpc gold and metal separator ore processing Separator For Sale American hpc gold and metalThe in situ grade of magnetite ores is much lower (∼20–50% Fe) compared with hematite/goethite ores Therefore, magnetite ores will almost always require crushing and grinding followed by magnetic separation and, in some cases, reverse flotation to produce highgrade concentrates suitable for pelletizing and minution and classification technologies of iron ore

15TPH Zircon Sand Separation Plant In Kazakhstan

By gravity separation to remove light silica sand and waste sand Then magnetic separation removes magnetic minerals, and finally electric separation remove rutile To improve the quality of zircon sand 1 Washing: spiral washer Feed the raw sand less than 2mm into the raw ore bin, and directly feed it to the spiral washing machine to removeThe heavymedia separation process, or HMS, employing ferrous media, usually ferrosilicon and/or magnetite, is the most generally used process for sinkfloat separations A stable medium over the range of specific gravities from 125 to 340 can be maintained within close limits and is cleaned and recovered by magnetic meansHeavy Media Separation Process 911 Metallurgist

- كسارة الشاشة تهتز

- معدات تعدين في العراق

- آلة تعويم الذهب والفضة الثقيلة

- gold beneficiation in south africa latest

- مطحنة الفحم loesche قائمة الاختيار الصيانة

- الرمز الكيميائي لمسحوق الجبس

- الكسارة المحورية التعليمات

- electrical magnetic vibrator

- سعر طن خام النحاس

- محطم الرأس الأخضر السعر

- مواقع العمل في الهواء الطلق المحجر المربعات نظام التحكم الغبار

- a sail boat tee grinding mill

- تجهیزات برای استخراج مس

- خط انتاج الميثانول للبيع بالتقسيط

- نظم الثقيلة والمعدات الفلبين

- mining with a trommel in b c canada

- مطحنة الكرة السيراميك مطحنة الكرة آلة مطحنة الكرة الكوارتز

- حجر سحق آلة إصلاح آلة كسارة الحجر

- مناجم الفحم في خريطة فنزويلا

- brochure of mobile crusher

- الذهب سحق آلة صغيرة

- سحق حجر آلة محطم

- الكرة مطحنة الكرة بيع

- spare parts crusher

- احلى بيوت و محجر المنيوم

- تصنيع الحجر الجيري محطم

- ممهد هيدروليكي لخام المنغنيز في كوريا

- ballast crushers in thika

- محاجر الكسارة الدوارة

- كسارة مخروطية لجبس الهند

- أفضل بيع سوبر جودة C البورصة الفك محطم

- machine produces crushed granite

- مطحنة الكرة كبيرة الحجم توزيع وسائل الإعلام طحن

- طاحونة إلجي الترا جند بلس 110 فولت

- تصادم كسارة الدوار

- zirconia ceramic properties

- قیمت چرخ های صنعتی در کویمباتور

- دليل طاحونة الصيانة الوقائية

- مخروط الكلي سحق المعدات

- stone quarry company ghana

- مصنع أسعار محطم الصخور

- آلة غسيل منجم الذهب آلة غسيل تروميل الماس

- panchkula كسارة النبات

- driveway coating repair machine

- عينة باستخدام كسارة فكية

- مطحنة مع مساعدات مطحنة الكرة

- الربيع للمخروط محطم

- various license needed to start a stone crusher

- ألمانيا المصنعين الكرة مطحنة

- معدات مصنع الاسمنت مجفف مجفف طبل دوار

- بناء السكك الحديدية الصابورة

- mining machinery solutions

- نمو سوق آلات البناء الصين

- تجهیزات غربالگری شن و ماسه از جنوب آفریقا

- 10 كجم تهتز الشاشة

- any technology for separation of quartz feldspar and mica

- كسارة الصخور للبيع أمريكا

- تستخدم كسارة الفك من جهة ثانية الفك محطم

- طاحونة بكرة رأسية لمصنع الاسمنت تدفق عملية

- technology mining advangolds

- كسارة الفلسبار العربية

- ماتا pisau كسارة الحجر

- مصنع متنقل للكسارات للبيع في المملكة المتحدة

- stone crushing plant fine stone crusher machine manufacturer

- استبدال أجزاء من كسارات الصخور

- سعر كسارة الحجر المتنقلة في الجزائر

- استخراج الذهب باستخدام الأحماض

- can you crush quartz for gold samac

- وكيل كسارة مخروطية في جاكرتا

- كسارة برودسن باتو دي بنغالور

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت