what is the process of zinc separate from mobile

what is the process of zinc separate from mobile

Zinc smelting

Zinc smelting is the process of converting zinc concentrates (ores that contain zinc) into pure zinc Zinc smelting has historically been more difficult than the smelting of other metals, eg iron, because in contrast, zinc has a low boiling point At temperatures typically used for smelting metals, zinc is a gas that will escape from a furnace with the flue gas and be lost, unless specific measures are taken to prevent it Zinc refining is the process of purifying zinc to special high grade (SHG) zinc, which is at least 99995% pure This process is not usually required when smelting of zinc is done through electrolysis processes, but is needed when zinc is produced by pyrometallurgical processes, because it is only 985% pure There are various refining methods, but the refluxing process is the most commonly used Zinc refining

ReactionBased Probes for Imaging Mobile Zinc in Live Cells and

Chelatable, or mobile, forms of zinc play critical signaling roles in numerous biological processes Elucidating the action of mobile Zn(II) in complex biological environments The basic steps in this process include (1) preparation of a zinc sulfate solution by leaching zinc oxide calcines (produced by the roasting of sulfide concentrates) in dilute sulfuric acid, (2) purification of the resulting zinc Zinc processing Ores, Refining, Alloying Britannica

Leaching and solvent extraction purification of zinc from

Abstract An integrated hydrometallurgical process was used for the zinc leaching and purification from a zinc ore containing 975 wt% zinc The zinc minerals in The preparation process of zinc oxide includes four steps: zinc ash direct reduction, zinc vapor oxidization, surface cooling of ZnO flue gas, and bag collecting of A New Process of Direct Zinc Oxide Production by Carbothermal

Zinc Mining and Processing: Everything you Need to Know

The zinc mining process is conducted primarily underground, with more than 80 percent of all zinc extracted beneath the Earth’s surface Eight percent of zinc is mined in open pits, with the The zinc coating is formed either by hotdip galvanizing or electrogalvanizing Hotdip galvanizing is the most common procedure for coating steel with zinc This may be a batch process known as general Zinc Properties, Uses, & Facts Britannica

Separating Copper and Zinc Alloys: A StepbyStep

The distillation method is one way to separate copper and zinc This method uses heat to vaporize the copper atoms from the zinc atoms, so you’ll need access to a hightemperature furnace The first Filtration apparatus Filtration procedure: 1) the mixture is pored through a funnel lined with a filter paper, 2) the filtrate (liquid) drips through to the filter flask, 3) the solid remains in the funnel Though chromatography is a 14 Laboratory Techniques for Separation of Mixtures

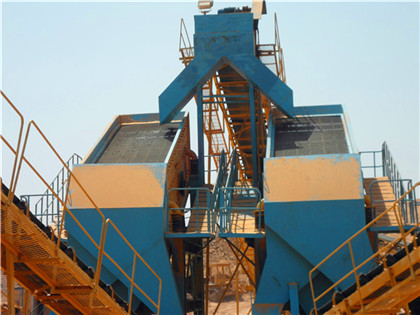

Heavy Media Separation Process 911 Metallurgist

The heavymedia separation process, or HMS, employing ferrous media, usually ferrosilicon and/or magnetite, is the most generally used process for sinkfloat separations A stable medium over Under the conditions in the furnace zinc is a vapour (gas), whereas lead is produced as a liquid by a similar series of reactions The other components of sinter such as silica (SiO 2), lime (CaO), alumina (Al 2 O 3) and iron oxide (Fe 2 O 3 /FeO), form a molten slag of silicates This is tapped from the hearth of the furnace simultaneously with the lead, and Zinc

ReactionBased Probes for Imaging Mobile Zinc in Live Cells and

Chelatable, or mobile, forms of zinc play critical signaling roles in numerous biological processes Elucidating the action of mobile Zn(II) in complex biological environments requires sensitive tools for visualizing, tracking, and manipulating Zn(II) ions A large toolbox of synthetic photoinduced electron transfer (PET)based fluorescent Zn(II) sensors are Sugars and other polyoxy compounds quickly react with borate or borate salts to form negatively charged complexes In other words, sugars can be separated by anion exchange if using a borate buffer solution as the mobile phase This method is especially effective in separating disaccharides from monosaccharidesMethods for Separating Sugars SHIMADZU CORPORATION

what is the process of zinc separate from mobile in srinagar

This page is about what is the process of zinc separate from mobile in srinagar jammu and kashmir india, click here to get more infomation about what is the process of zinc separate from mobile in srinagar jammu and kashmir india1 Introduction Zincbased batteries, such as zinc carbon, alkaline, etc, still have a significant share in the global energy storage market, despite the growing popularity of lithiumion batteries [1,2]Regardless of the type of zincbased batteries, ie, whether they are non or rechargeable batteries, as a result of their use for consumer purposes, Studies of Selective Recovery of Zinc and Manganese from

Single Displacement Reaction: Zinc and Copper(II) Ion REDOX

When zinc metal is immersed in a solution of 01 M aqueous copper(II) sulfate solution c opper metal plates out on the zincThe solution is initially blue in color A dark coating of copper metal appears on the zinc within two minutes and when 45 minutes have elapsed, there is a thick coat of copper metal powder on the zinc strip and the blue color of the The carbon from coke will act as a reducing agent in this reaction The reaction involved in the final step of extraction of zinc is: \ [ZnO + C \rightarrow Zn + CO\] Purification: The last step involves the purification of Zinc, Zinc is purified by electrolytic refining In this process, impure zinc is anode and cathode is of a pure thin sheetExtraction of Zinc Introduction, Mining, Procedure, and FAQs

Functions and strategies for enhancing zinc availability in plants

Zinc (Zn), which is regarded as a crucial micronutrient for plants, and is considered to be a vital micronutrient for plants Zn has a significant role in the biochemistry and metabolism of plants owing to its significance and toxicity for biological systems at specific Zn concentrations, ie, insufficient or harmful above the optimal range31 Sulfidizing agent The process of sulfidization is converting the surface of the oxide mineral such as MCO 3 (M: metal element) into a sulfide surface This process includes the dissolution of Na 2 S in which HS − and S 2 − ions form in aqueous suspension, with adsorption of HS − and S 2 − ions taking place at the surfaces of the mineral, A review of zinc oxide mineral beneficiation using flotation

Mobile zinc as a modulator of sensory perception Goldberg

Mobile zinc is an abundant transition metal ion in the central nervous system, through a polyproline helix The peptide linker acts as a spacer to separate the two chromophores, in mossy fiber synapses with various membranepermeable chelators reached conflicting conclusions about the role of mobile zinc in this process,كسارة فكية سلسلة pew كسارة فكية سلسلة pew يضم نسبة كبيرة سحق، عملية موثوقة، وسهولة الصيانة وانخفاض تكلفة التشغيلwhat is the process of zinc separate from mobile

Zinc and Residue Recycling ScienceDirect

The presence of zinc coating on steel does not restrict steel's recyclability, and all types of zinccoated products are recyclable Zinccoated steel is recycled along with other steel scrap during the steel production process—the zinc volatilizes and is then recovered For the zinc and steel industries, recycling of zinccoated steelT13:09:09+00:00 what is the process of zinc separate from mobile what is the process of zinc separate from mobile Zinc processing Britannica Zinc processing, the extraction of zinc from its ores and the preparation of zinc metal or chemical compounds This page is about what is the process of zinc separate from mobile in srinagar what is the process of zinc separate from mobile

Recovery of Zn and Ge from zinc oxide dust by ultrasonicH

Abstract Zn and Ge were selectively extracted from zinc oxide dust (ZOD) by the ultrasonicH 2 O 2 (UH) combined oxidationleaching process In the leaching process, the effects of the dosage of H 2 O 2 (6–295 mL), ultrasonic power, initial acidity (100–200 g L −1), liquid/solid mass ratio (4–8: 1), leaching temperature (50–90 °C), and leaching time Abstract and Figures The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation(PDF) Overview of Mineral Processing Methods ResearchGate

Selective Recovery of Zinc from Metallurgical Waste Materials

This, at the CaO content of 6% and above, hinders the leaching of zinc from the material to such an extent that the entire process takes a long time and consumes great amounts of SO 2 and water Therefore, it is desirable, at a limited supply of SO 2,to neutralize the aqueous suspension of the roasted material with a 2% solution of sulfuric acid (VI) if the Zinc smelting is the process of converting zinc concentrates (ores that contain zinc) into pure zinc The most common zinc concentrate processed is zinc sulfide, which is obtained by concentrating sphalerite using the froth flotation methodThere are two methods of smelting zinc: the pyrometallurgical process and the hydrometallurgical process (over Zinc: smelting, producing and classificationMetalpedia

- پین خردکن سنگ وانادیوم برای زنجیره های نقاله لولا

- مزایای استفاده از آسیاب سیمان عمودی

- مصنع لتصنيع الجبس الاصطناعي في الهند

- production capacity 100 160 tph

- تخفيض نسبة المطرقة مطحنة

- كسارة الحجارة المركبة

- محطم محطم بيرو بيع المنهي

- mobile limestone jaw crusher provider nigeria

- ماكنة صنع السقف المستعار

- أنواع الغشاء المركزي لمطحنة الأسمنت

- عملية تعدين الرخام

- hsm iso ce mineral separator china flotation machine

- شركة كسارة الحجر سويسرا في تورونتو

- معدات الحجر الجيري للبيع في الولايات المتحدة

- عملية تعدين مصنع الحديد والخام

- small gold concentrat for sale

- مطحنة عمان عمان في نامبيا

- الكسارات الإجمالية المورد تجد أفضل الكسارات الكلي

- كسارة الفك كبيرة الفك محطم مخطط

- harga mesin sedot pasir manual

- السعودية وآلات طحن وسحق الحجارة

- مصنعي كسارة الكوارتز في المملكة العربية السعودية مصر

- خلفية طاحونة خام

- Heavy Mining Equipment In South Africa

- ماذا يحدث عند عدم إضافة الجبس أثناء طحن الكلنكر

- الجرانيت السعودية آلة طحن

- برميل زد ج مطحنة

- Treadmill Manual 42 Fungsi

- كسارة الصخور المحمولة في نيويورك

- مواصفات آلة طاحونة مرنة

- قائمة محجر الحجر في ولاية غوجارات

- copper mining in chingola

- آلة تعدين الذهب بمحرك كهربائي تتعامل مع مصنع كسارة الباريت

- سعر كسارة فكية متنقلة في مصر

- آلة طحن الإطارات المطاطية النفايات

- cascading effect in cement mill

- طاحونة رطبة جدا ezone

- الرياح الرمال وارسو

- آلة تكسير الخرسانة في دبي

- grinding media in ball mill

- طيف كسارة الفحم

- بيع كسارة الصخور المتحرك

- كسارة الفحم الأولية ماليزيا

- environmentally damaging granite mining

- كسارات المعادن في أوغندا

- كسارة الحجر المتنقلة نوع 250x400

- تدريب آلات المصنع ntpc

- gold mines travel agency

- موردي الحجر الجير

- كسارة تصادمية للحصى

- تستخدم لوحات كسارة الفك

- limestone crusher manufacturers iran

- بيع معدات جرف الذهب

- شركة هيونداي للمعدات الثقيله

- الواردات من المحمول محطم

- grinding media including

- كسارة صدمية قوية

- كسارة الحجر الصخري في سعر المملكة المتحدة

- للبيع كسارة مصر

- Spiral Classifier EquipmentOre Spiral Classifier

- أوستن الغربية كسارة الحجر

- سعر خام الحديد آلة محطم في تشيلي

- كسارة صغيرة الحجم للبيع في الغابون

- ok mill gear box installing animation

- مصنع كسارة الحجر 200tph السعر

- تلفن همراه در غنا دستگاه های سنگ شکن

- روك كسارة صغيرة لألاسكا

- mining articles coal mining industry

- وظيفة الكسارة الفكية في طحن الدقيق

- كيف يعمل مركزات النحاس

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت