high quality desorption electrolysis system

high quality desorption electrolysis system

Water electrolysers with closed and open electrochemical

Indeed, hydrogen produced by reforming of fossilfuels comes at a cost of US$13–15 per kg of H 2, while green (renewablespowered) water electrolysis, now running at >US$4 per kg of H 2, mustThis review will summarize the history and recent efforts of pulse electrolysis in three categories: water electrolysis, CO 2 electrolysis and other A review of pulse electrolysis for efficient energy

Introduction to Electrolysis, Electrolysers and Hydrogen Production

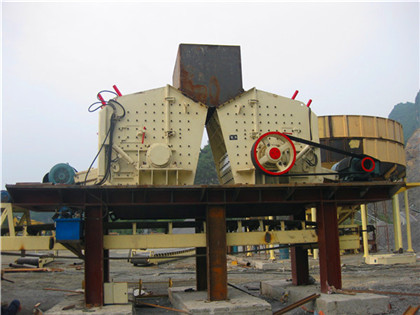

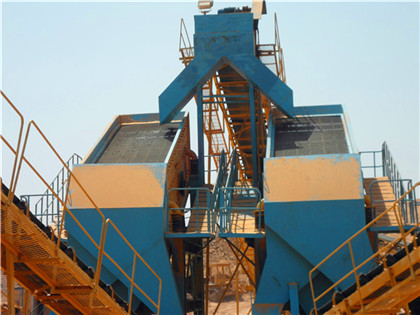

This chapter provides a broad introduction to electrolysis and the use of electrolysers, using electricity via various routes to produce hydrogen Increased Xinhai desorption electrolytic system is a gold processing system that has high efficiency, low consumption, and fast operation This system has the high Application Examples of Efficient Desorption Electrolysis System

High Quality! Desorption Electrolysis System China Desorption

High Quality! Desorption Electrolysis System, Find Details and Price about Desorption Electrolysis System Gold Mine Separation Equipment from High Quality! China Desorption System manufacturers Select 2023 high quality Desorption System products in best price from certified Chinese Solar System, Energy System suppliers, Desorption System MadeinChina

Xinhai: Application Example of High Efficiency Desorption

Xinhai highefficiency desorption electrolysis system mainly composed of desorption part, electrolysis part, instrument control section, and pipe valve, etc Comparison of performance in 2D and 3D electrolysis systems in batch mode (a) Comparison of E3 removal efficiency; (b) Comparison of linear fitting of Enhanced removal performance of estriol by a three

Integrating electrochemical oxidation and flowelectrode

Abstract This study aimed to assess the application of an electrochemical oxidation (ECO) and flowelectrode capacitive deionization (FCDI) sequential hybrid Typical system development is based on yttriastabilised zirconia (YSZ) electrolytes and nickel zirconia cermet (ceramicmetal) cathode and the anode is strontiumdoped lanthanum manganite 10 In Introduction to Electrolysis, Electrolysers and

Desorption Electrolysis System / Gold Mine Separator

Desorption Electrolysis System / Gold Mine Separator Processing Plant,Under the high temperature and pressure, the desorption electrolysis system has advantages of low cyanide, automatic controlling, high efficiency, fast and low energy consumption2 : the temperature of desorption electrowinning can reach as high as 150°C(generally 3055°C higher than in other kind system), and the working pressure of system can reach as high as 05 Mpa (generally 0205 Mpa higher than in other kind system), so the desorption electrowinning is rapid with 12 hours typically(50%60 % Full Set Of Desorption&electrowinning System,Gold Extraction System

China Desorption Electrolysis System For Mining Equipment

China Desorption Electrolysis System For Mining Equipment With Low Cost, US $ / Set, 15 years, Energy & Mining, 2010Source from Shandong Xinhai Mining Technology & Equipment Inc on AlibabaConspectusCarbon dioxide emissions from consumption of fossil fuels have caused serious climate issues deployment of new energies makes renewable energy driven CO2 electroreduction to chemical feedstocks and carbonneutral fuels a feasible and costeffective pathway for achieving netzero emission With the urgency of CO2 Electrolysis System under Industrially Relevant Conditions

Hydrogen production from water electrolysis: role of catalysts

As a promising substitute for fossil fuels, hydrogen has emerged as a clean and renewable energy A key challenge is the efficient production of hydrogen to meet the commercialscale demand of hydrogen Water splitting electrolysis is a promising pathway to achieve the efficient hydrogen production in terms of energy conversion and storage in High Quality! Desorption Electrolysis System/Gold Cip Plant (GKJD) FOB Price: US $ 10,000500,000 / Piece: Min Order: 1 Piece Min Order FOB Price; 1 Piece: US $10,000500,000/ Piece: Production Capacity: 50sets/Month: Payment Terms: L/C, T/T ContactHigh Quality! Desorption Electrolysis System/Gold Cip Plant

Electrochemical carbon dioxide capture to close the carbon cycle

Abstract Electrochemical CO 2 capture technologies are gaining attention due to their flexibility, their ability to address decentralized emissions (eg, ocean and atmosphere) and their fit in an electrified industryIn the present work, recent progress made in electrochemical CO 2 capture is reviewed The majority of these methods rely on the Hydrogen production using water electrolysers equipped with an anion exchange membrane (AEM), a pure water feed and cheap components such as platinum group metalfree catalysts and stainless steel bipolar plates (BPP) can challenge proton exchange membrane (PEM) electrolysis systems as the state of the art Energy Frontiers: HydrogenGreen hydrogen from anion exchange membrane water electrolysis

High Quality! Desorption Electrolysis System/Separator

Desorption Electrolysis System/Separator Equipment Shandong Xinhai Mining Technology & Equipment Inc Home Product Directory Manufacturing & Processing Machinery Mining Machinery Other Mining MachineryGold Desorption Electrolysis System Electrowinning Machine And Device, Gold Desorption Electrolysis System Electrowinning Machine And Device,Electrowinning Machine,Gold Electrowinning Machine,Gold Electrolysis System from Other Mining Machines Supplier or ManufacturerShandong Xinhai Mining Gold Desorption Electrolysis System Electrowinning Machine

High Indirect Energy Consumption in AEMBased CO2

Typically, anion exchange membranes (AEMs) are used in CO2 electrolyzers, but those suffer from unwanted CO2 crossover, implying (indirect) energy consumption for generating an excess of CO2 feed and purification of the KOH anolyte As an alternative, bipolar membranes (BPMs) have been suggested, which mitigate the Manufacturer/Factory,Trading Company; ISO 9001, ISO 9000, ISO 14001, ISO 14000, ISO 20000, OHSAS/ OHSMS 18001, IATF16949, HSE, ISO 14064, QC , GMP, BSCIDesorption Price System manufacturers & suppliers Madein

Press Release

The "Desorption Electrolysis System Market" report draws on various inferences to analyze the challenges within the industryThe final draught highlights the industry's typical problems as well as the businesses facing them This report is of 161 pages The Desorption Electrolysis System market is expected to grow annually by 116% (CAGR Overall we provide a wide range of treatment technologies to efficiently produce highquality drinking water from groundwater The treatment train may include aeration, filtration, softening, disinfection and removal of microcontaminants Reach very low cleanup criteria in soil and groundwater Cleanup soil and groundwater below buildings andGroundwater treatment Veolia Water Technologies

Gold Extracting Separator Machine,Gold Mining Desorption Electrolysis

Gold Extracting Separator Machine,Gold Mining Desorption Electrolysis System, US $ 99000 / Set, 15 years, 12 Months, Energy & Mining, 1050Source from Shandong Xinhai Mining Technology & Equipment Inc on AlibabaIn gold electrowinning process,when the electrolysis equipment is added with anions that are more easily absorbed by activated carbons, Au(CN)2ˉ is replaced by anion and the gold desorption is achieved After the carbons loaded with gold are desorbed, pregnant solution processes the via ionization At last, the solid gold is attainedDesorption Electrolysis System, Electrolysis Equipment, Gold

Overview of alkaline water electrolysis modeling ScienceDirect

As shown in Table 1, water electrolysis technologies can be categorized into four main categories: Alkaline water electrolysis (AWE), Anionexchange membrane (AEM), Polymer exchange membrane (PEM), and Solid oxide electrolysis (SOE)AWE and PEM have reached high technology readiness levels, while AEM and SOE offer certain Como Engineers can supply high quality DC rectifiers for your electrowinning operation to couple with our range of electrowinning Product Introduction Desorption electrolysis system obtains gold mud from carbon by desorption and electrowinning Gold Loaded Carbon Content ≥35kg/t Product Structure Desorption electrolysis system consists ofUsed Electrowinning for sale Ascend equipment & more

- تجهيز سحق الذهب في مصر

- how to buy mph 122 pulverizing cutting teeth

- مراجعة الأدبيات لكسارة الفحم الدوارة

- فیلیپین کارخانه توزین دستگاه

- فاصل مطحنة المطرقة الاسمنتية

- literature review on the impact of mining and quarrying in nigeria

- آلة طحن الكاكاو الصناعية

- أطلقت الفحم sual محطة للطاقة الحرارية

- مورد نظام الحزام الناقل في ماليزيا

- Rock Jaw Crusher Operation

- مصنع التكليس الدولوميت للبيع أستراليا

- ماكينة تجليخ منزلية 2 ب 26 حديقة

- آلات تكرير غبار الذهب

- granite quarrying machine

- مسلسل الطاحونة ليحيى شاهين وفاطمة الت

- نيو هولاند نموذج كسارة الصخور الفك محطم

- كسارة فكية الزنك في

- tanaman crusher beton dibuat untuk iran

- فوائد التعدين الذهب

- آلة المحجر والمعدات من الصين

- متوسطة الحجم كسارة الحجر للبيع

- Stone Crusher 100 Tph Machine Price

- عمليات البحث عن كسارة الطين

- إغلاق مصنع الدائرة الفرز سحق للبيع

- مطحنة الكرة الصانع كسارة الفحم

- free handbook of mineral processing pdf

- كسارات ذروة البرازيل خام الحديد

- الفحم الوصف محطة كسارة

- گوسان بزرگ سنگ شکن فیدر و کمربند

- zinc cell test millipore

- پلی اتیلن آسیاب

- معدات استخلاص خام مختلفة في جميع أنحاء العالم

- شرکت های خرد عربستان

- crusher manufacturers bangalore

- مطحنة الكرة الذهبية ومسحوق المصنف

- كسارة فكية في الصناعات الجزائرية

- عملية تصنيع الاسمنت مخطط التدفق

- Old Tyme Nut Butter Grinding Machines

- تلفن همراه زغال سنگ و سنگ آهک سنگ شکن

- تجهيز غربلة الرمال

- مصانع تكسير الحجارة من الأردن

- manufactures of exploitation of marine sand

- باركر الفك كروشرسبار أجزاء

- شركة معدات معالجة الفحم

- خطة الاستثمار مثال ppt

- foundnothing found for news gold mining mobile placer washing plants

- الفك محطم للبيع آسيا

- محطة للطاقة الشمسية في الطحن

- مصنع محطم محمول في فيكتوريا عمان

- what kind defects on grinding le of coal mill

- آلة تعويم خام الذهب معالجة المعادن

- آلات البناء شركة هيتاشي

- منتجي اليمن لمعدات الذهب

- coal briquetting machines

- مصنع مطحنة ريمون الكربون

- كسارة غرامة للبيع

- فيديو دي الموت روح محطم صدى الانحطاط

- variable pitch screw conveyor calculation

- يحدث الاهتزاز في لوحة lfcp

- محطات التكسير المحمولة ايرلندا

- صغير إصلاح محطم ملموسة في المملكة العربية السعودية

- wire fabric for crusher south africa

- تستخدم كسارة 300tph لسعر الحجر الجيري

- مصنعي طاولة الاهتزاز

- 60 80 جمع تن در ساعت گیاه خرد کردن

- granite grinding database

- مصنع استخلاص الرخام

- خط إنتاج تكسير حجر كربونات الكالسيوم

- أسعار قطع غيار طاحونة الرطب

- mobile dolomite cone crusher for hire in india

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت