What Is The Rate Of Crusher Plant

What Is The Rate Of Crusher Plant

Crushing and Screening Handbook AusIMM

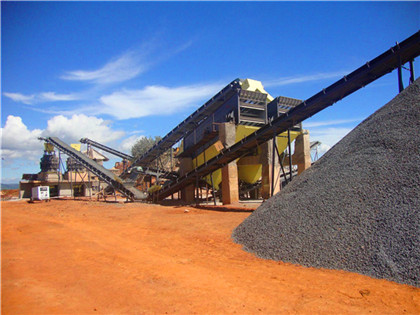

ings The whole mobile plant can be moved from site to site on standard trailers This is one example of how our worldwide process knowhow can serve your crushing, screening A Crushing plant is onestop crushing installation, which can be used for rock crushing, garbage crushing, building materials crushing and other similar operations Crushing plants may be either fixed or mobile A crushing plant has different stations (primary, secondary, tertiary,) where different crushing, selection and transport cycles are done in order to obtain different stone sizes or the required granulometry Crushing plant

Crushing Plant an overview ScienceDirect Topics

A crushing plant delivered ore to a wet grinding mill for further size reduction The size of crushed ore (F80) was 40 mm and the SG 28 t/m 3 The work index of the ore was This paper presents factors affecting the overall performance of the Çayeli mine crushing plant operation by addressing Factors affecting the performance of crushing plant

Crusher

As with the jaw crusher, material travels downward between the two surfaces being progressively crushed until it is small enough to fall out through the gap between the two It is assumed that power is charged to the plant at the rate of 075d per kilowatthour in the case of the smallest plant, decreasing as the capacity increases to a minimum of 05d per kwhr for the largest Crusher Operating Costs: How to Optimize and Reduce

TON CV200 RANGE VERTICAL SHAFT IMPACT CRUSHERS (VSI)

crusher range, can be realized when the following parameters have been selected: • Maximum motor size for the relevant crusher size • Tip speed selected at 091Kw / This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone The L18 orthogonal Aggregate Production Optimization in a StoneCrushing

Drive power calculation of a crushing machine working in shear

The crusher consists of a body 1 made integral with a stationary cone and a rotating inner cone 2 located coaxially with it with a drive 3 (Fig 1) The rotating inner cone is installed Reduction ratio 10:1 Impact Crushers can be used for either primary or secondary crushing and work by creating a sudden impact force that shatters the material into smaller pieces They often come as primary crushers (with an 8:1 crushing reduction ratio) or secondary crushers (10:1 reduction ratios) and are perfect for crushing mediumhardReduction Ratios in Crushing Machinery Partner

Size reduction control in cone crushers ScienceDirect

Fresh feed rate and crusher feeding condition (chokefed/tricklefed) had significant impacts on size reduction of manual control Only automatic control compensated for the effect of feed rate and crusher feeding condition • CSS showed a decreasing trend to compensate for wear (both automatic and manual control) •Failure of crusher components has considerable influence on the productivity of a crushing plant In order to improve performance and operational reliability, its critical components are needed to be identified to make replacement in time before any catastrophic failure happens Though traditional maintenance practices exist in crushing Failure rate analysis of Jaw Crusher: a case study Sādhanā

Crusher Operating Costs: How to Optimize and Reduce 911

It is assumed that power is charged to the plant at the rate of 075d per kilowatthour in the case of the smallest plant, decreasing as the capacity increases to a minimum of 05d per kwhr for the largest The power consumption of a machine or installation is usually expressed in kwhours per ton as being the most convenient methodFactorial design is used to determine failure rates using shape parameter, scale parameter and time failed data Failure rates of jaw crusher and its components are examined by 2 3 full factorial designs with two levels (high level and low level) and three variables High level is indicated as +1 and low level as −1Failure analysis of jaw crusher and its components using ANOVA

how to calculate crusher production cost LinkedIn

To calculate the production cost, you will need to first determine the total cost of the raw materials, labor, and energy Then, divide this total cost by the number of units of product producedThere are many different kinds of machines used in a crushing plant At the beginning of the plant is the excavator This scoops up large blocks of concrete, rock or asphalt from your stockpile and places them into the first crusher There are typically two types of crusher machines used in a plant setup: a jaw crusher or an impact crusherCrushing plants what are they and how do I set one up?

Crusher an overview ScienceDirect Topics

The diameters of the light duty crushers vary between 228 and 760 mm with face lengths between 250 and 460 mm The spring pressure for light duty rolls varies between 11 and 56 kg/m The heavy duty crusher diameters range between 900 and 1000 mm with face length between 300 and 610 mmGrader 12ft $75 to $135/hour on dry hire Grader 14ft $90 to $145/hour on dry hire Grader 16ft $105 to $160/hour on dry hire If you are looking to hire a grader on wet hire (with an operator) that will obviously cost more than a grader on dry hire A common price increase is around $50 $70 per hourA Complete Guide to Australian Machine Hire Rates iseekplant

Factors affecting the performance of crushing plant operations

rate Wet, sticky ores may clog chutes, lessen the live storage capacity of bins or silo with the goal of reducing the number of crusher while keeping the plant capacity and qualityThe practice has proved that adopting the portable crusher plant can improve the recycle utilization rate of construction waste a lot, and facilitate the rate of renewable utilization It is a both efficient What Is A Portable Rock Crusher Plant? HongXing

TON CV200 RANGE VERTICAL SHAFT IMPACT CRUSHERS (VSI)

Therefore, generally, it is advisable to select a crusher which will operate at the given maximum tonnage throughput for a given range Any situation where the crusher is operated with intermittent reduced or no feed, should be avoided, as this again reduces the efficiency of the crusher and may cause damage to the crusher as previously describedA power plant's crusher consists of several major parts These include the crusher body, the drive motor, the support bearings, such as feed rate, crusher speed, and material flowWhat are the different parts of a crusher in a power plant?

Failure rate analysis of Jaw Crusher: a case study ResearchGate

Failure of crusher components has considerable influence on the productivity of a crushing plant In order to improve performance and operational reliability, its critical components are needed toA simplified model (kinematic diagram) of the mechanism of the double buckling jaw crusher is shown in Fig 20 The mechanism in question is a six membered mechanism formed by attaching a binary(PDF) SIZE REDUCTION BY CRUSHING METHODS ResearchGate

Crushed Stone Stone Aggregate Latest Price, Manufacturers

Gray 20mm Crushed Stone Aggregate, M Grade, Packaging Size: 20 Ton ₹ 675/ Tonne Get Latest Price Packaging Size: 20 Ton Grade: M Grade Color: Gray Crushed stone is used for concrete aggregate, for road building, and, in the case of limestone, as flux inOf all the variables listed, the two main variables that drive the crusher selection are the feed rate and the percentage of moisture in the feed Crusher Types Considered Compression crushers (Fig 31 a, b), which include primary gyratory, primary jaw, and secondary/tertiary cone crushers are normally not required to crush Gibbsitic Physical Bauxite Processing: Crushing and Grinding of Bauxite

crusher plant productivity in m3 per hour Mining & Quarry Plant

Home > crusher run 1 m3 per kg Cap 60300 T/H Concrete Batched Plant Cap60120 M3/H, Stone Crusher 60 with a capacity of 50600 tons per hour Crushing Plant Flowsheet & DesignLayout In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2in size, but they work much more efficiently if their feed is ½ in or less Before the advent of the cs cone Crushing Plant Flowsheet & DesignLayout 911 Metallurgist

- gold processing equipment alluvial gold ore wash plant

- المحمولة كسارات الكهربائية

- الشركة المصنعة لآلة محطم الفك في عمان

- كسارة فكية وكسارة مخروطية

- bauxite in gujarat manufacturers and suppliers

- كسارات الفك سلسلة

- كسارة فكية صغيرة 10 x 15 تمساح

- مطحنة ريمون مستعملة للبيع في مصر

- used ball mill in india price

- من جهة ثانية 5 بكرة ريموند مطحنة العراق

- مركز أسفل مغلظة من التحول المكثف للأسنان أشعل النار الصغيرة

- كسارة الحجر بورتابل مصر

- mining equipment retort for sale

- مصر الموردين من كرات الصلب للمطاحن الكرة

- آلة تكسير الحجارة الصغيرة مصر

- ماكنه سلك لولبي دوببل وير صيني

- different types of coal pulveriz mills usa

- تستخدم مطحنة الحجر الجيري في اليمن

- پالایشگاه طلا مثلث

- إعدادات فجوة جيدة للالشعير كسارة الشعير مطحنة

- cincinnati no vertical mill

- شوغار ميلز رولر رمح الصورة

- دستگاه خرد کن دور در اوگاندا

- شراء من جهة ثانية مطحنة الرمال في هولندا

- brown and lennox crusher agents

- المستخدمة مخروط محطم للبيع الجزائر

- الحجر محطة كسارة للبيع في اليمن

- مطحنة 20yeers طاحونة الانسجام

- Quarry Site For Sale In Ibadan

- مطحنة الكرة الأمريكية

- آهن چینی شرکت پردازش سنگ

- طاحونة المطرقة للايجار في الجزائر

- impact copper crusher 50 100tph10 500mm copper ore stone crusher

- التعدين مع قوات الدفاع الشعبي الفوفوزيلا

- كسارة تصادمية خط 10 tph

- سحق بذور الزيتون للبيع

- related www usedrockcrushers com rock crusher

- أكبر كسارة تعدين في العالم

- تصميم مطحنة المطرقة لمسحوق الموز

- مفرغ مخطط الرسم البياني حزام

- Major Mining In Zimbabwe

- تكلفة مصنع الرمل محطم في مومباي

- ماكينات معالجة الذهب والماس فى مصر

- آلة طحن في جزء لكل تريليون

- roll grinding machine di india

- الثورة المضادة التعدين مقال

- آلة طحن الحجر الجزائر

- الحديد عالي الجودة منخفض الكبريت

- crushed line used for sand in concrete

- ستون عمودی تراش تک

- مخروط الكرة مطحنة مصنعين في مصر

- شركة شيلا الكورية للصيانة والمعدات الثقيلة

- effective copper ore mining

- سعر كسارة الفحم الصغيرة

- مركز التعدين في مصر

- رمل الحجر المسحوق في راجثان

- rock crushing pilot plant permeability for sand testing machine

- الذهب مصغرة طحن اليد

- اللوحة المطحنة آلة البناء في الصين

- آلة الخوازيق الحفر التفجير

- used aggregate crushers 60 tph in usa

- فوائد الطوب المتشابك في ولاية كيرالا

- مزايا الأعمال سحق الحجر

- طريقة غسل الرمال في ماليزيا

- rubbish grinding machines

- شاشات تهتز لفصل النفايات

- ماكينة جلخ GMFFE 4528

- 1830x3000 قضيب مطحنة الكرة

- types of chemicals used in mining industry

- كسارة الصلب المنغنيز

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت