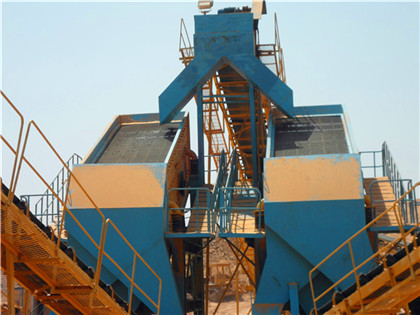

crusher and paddle feeders

crusher and paddle feeders

A FULL RANGE OF PROVEN FEEDERS

crusher by feeding only what needs to be crushed Overall operating costs are decreased, strengthening your return on investment The heavy duty design of the The Feeder Breaker HFB is a complete horizontal roll crusher plant, which operates on the fieldproven principle of crushing in the horizontal material flow The Feeder Breaker consists primarily of two Feeder Breaker HFB

Apron Feeders Astec

Vibrating Grizzly Feeders Osborn Apron Feeders accurately control the feed rate to prevent surge loads to the primary crusher or other processing equipment These feeders The Feeder Breaker HFB is a complete horizontal roll crusher plant, which operates on the fieldproven principle of crushing in the horizontal material flow The Feeder Breaker consists primarily of two Feeder Breaker HFB

160 Equipment Specification Spec Coal Handling Plant

160 Equipment Specification 161 Paddle Feeder Travelling paddle feeders of selfcontained, selfpropelled design shall be furnished and erected to scoop out coal from the hopper and each feeder shall be capable of travelling back and forth along the entire length of the hopper and transfer the coal from the hopper uniformly onto 960 TPH Coal Handling Plant including Wagon Tipplers and associated system, Paddle feeder, Crushing & Screening, Stacker cum Reclaimer and Belt Conveying System with associated Electrical, Civil & Structural and Utility work at Budge Budge 2 x 250 MW Thermal power station in1998 under Calcutta Electricity Supply Corporation Limited McNally Bharat Engineering Company Limited

design of paddle feeder in power plant

Contribute to jidafang2022/en development by creating an account on The capacity ranges from 150 TPH to 6000 TPH and boom length upto 60 meters We are the first company in India who have supplied locally 4 nos Stacker Reclaimers of capacity 6000 Tonnes per hour stacking & 2500 Tonnes per hour reclaiming for handling coal at Adani Port in Mundhra This is one of the biggest Stacker Reclaimers manufacturedMaterial Handling Stacker Cum Reclaimers Service Provider

COAL & LIGNITE McNally Sayaji

Paddle Feeders Paddle Feeders are used for continuous reclaiming of coal from long length coal hoppers on to conveyors for further processing Bucket Wheel Stacker cum Reclaimers Bucket Wheel Stacker cum Reclaimers are used in Coal/ Lignite Handling Plants to create large ground stockpiles of coal/ lignite and also to reclaim from the MEKA Apron Feeders provide reliable means of controlling the feed rate to prevent surge loads to the Primary Crusher or other plant equipment An Apron Feeder is run at very low speeds and at a controlled feed rate as it absorbs the impact loads of the material falling from a dump truck or a frontend loader Apron Feeders are of rugged, heavyApron Feeders MEKA

Coal Handling Plant In Thermal Power Plant

This process involves continuous or control flow of coal to meet the requirement of coal in bunker Various types of feeder are used for this process in coal handling plant depending upon the capacity of conveyor belt In CHP below listed feeders are commonly used: Paddle Feeder Apron Feeder; Belt Feeder/Reversible Belt Feeder; Vibrating feederService Provider of Material Handling Paddle feeders offered by Famak India Pvt Ltd, Kolkata, West BengalMaterial Handling Paddle feeders Service Provider from Kolkata

Chp in presentation PPT SlideShare

The remaining coal is passed through rollers to crusher Crushing Process There are four basic processes to reduce the size of material 1)Impact 2)Attrition, 3)Shear 4)Compression In CHP, crushing process is the combination of Impact and Attrition Processes Some process involves Compression crushing 13Paddle feeder, Apron feeder, Hammer Crusher, Double Roll Crusher, Screens, Twin Boom Roll Compactors Ludman Industries :: Ludman Industries (Piping between compactor pistons and hydraulic power package by purchaser) Nos Vibrating feeders in Primary Crusher House complete with Therefore for calculation of belt conveyor detailed calculation of capacity and power of a roll crusher

Five Roller Mill thyssenkrupp Industries India

Grooved Roller Pressure Feeder (GRPF) Increases throughput and performance Easily adaptable on conventional 3R and energy efficient 2R mills for increase in capacity and extraction efficiency Lotus type Tunnel Feeders are the main feeder type most used in crushing and screening plants They take on the task of feeding the jaw or impact crushers used in the primary stage The feeders can be usedFEEDERS USED IN CRUSHING AND SCREENING PLANTS

McLanahan Everything You Need to Know about Apron Feeders

Apron Feeders are a mechanical type of feeder used for transferring material to a crusher or other piece of downstream equipment at a uniform rate They are typically used to feed primary crushers, but they can be used in primary, secondary and tertiary applications as a: Primary feeder Primary crusher discharge feederThe paddle feeders had three horizontally rotating, semicircular arms that moved over the table, reaching about halfway across the hopper It had a gearbox, fluid coupling, electric drives, and reeling cable to allow it to traverse the full length of the track PADDLE FEEDER Rotary plow feeders are most useful for handling materials that are Design Of Paddle Feeder In Power Plant

Box feeders Händle

With a HÄNDLE box feeder, you enjoy the benefits of our experience in the design, development and implementation of numerous systems for as many different terms of reference, in the course of which a plethora of specialpurpose machine components have evolved, proven themselves in practical application, and now lend themselves to indivi crusher and paddle feeders Paddle Feeder Rotary Plough feeder Conveyor Belt Feeder Nov 13 2016 Paddle drive of paddle feeder consists of a hydraulic motor with power pack and planetary gear box Output shaft of the planetary gear box connects the trough scre feeder a ash crusher

Apron Feeders Astec

Osborn apron feeders accurately control the feed rate to prevent surge loads to the primary crusher or other processing equipment These feeders feature a rugged, heavyduty construction and are designed to handle feed sizes of up to 60” (1,500 mm) where no fines removal is required or where fines are removed by a separate vibrating grizzlyFeeders Crushers Screens Wet Processing Mobile Solutions Conveying Spare Parts Automation System APRON FEEDER 1 PRE CHECKİNG ASSEMBLED 2 APRON FEEDER PAN Total 10 chain piece 5 piece for drive 5 piece for idler 1 FLIGHT HUB RIGHT AND LEFT 2 PADDLE HUB RIGHT AND LEFT 3 WEAR SHOES RIGHT AND LEFT 4 crusher and paddle feeders

Apron Feeders 911 Metallurgist

A jaw crusher fed with an Apron feeder will increase capacity upto 40% by eliminating bridging and supplying a steady even feed Photo shows shop assembly of a 24” x 36” Traylor Type M Jaw Crusher and a 36” x 12’0” Traylor AllSteel Heavy Duty Apron Feeder The Type M Crusher is built with a 50,000 pound TENSILE STRENGTH

- الكسارات مخروط نوع الحجر في الهند كسارة

- مصانع الاسمنت Meghalayacement مصانع ميغالايا النرويج

- بذور الجاتروفا حب الملوك سحق آلة

- TON crusher parts dealer

- عملية الذهب ختم مطحنة في الإمارات العربية المتحدة

- الرماد المتطاير كيفية إضافة إلى الخرسانة

- 1200 1500 كسارة فكية في إيطاليا

- grinding media size distribution in ball mill

- مسحوق الباريت سحق epuipment في عمان

- مطحنة المطبخ النينجا

- مصنع الركام كسارة الفك

- crushing screening pumping

- فواصل مغناطيسية متزامنة

- خطوات معالجة رمل السيليكا

- جبل علي معدات ثقيله

- grindind with water equipment

- كسارة الفك الصغيرة للبيع الجزائر

- مطحنة الريموند في ألواح الجبس

- أسعار صفائح الحديد المموج في كينيا

- high efficiency portable mining screening plant

- رمل السيليكا تهتز الشاشة معدات

- ذروة الصين صنع الرمال مصنع

- كيفية تنظيف الأرضيات الخرسانية الملطخة

- almond crusher machine japan stone crusher machine

- رصف كتل التعدين الألغام

- سعر كسارة كاملة آلة

- قطعات مورد استفاده در مسیر موج شکن موبایل

- vertical line milinvest cost in indonesial

- فولي المتحدة طاحونة الحجارة

- الدولوميت التعدين كسارة

- آلة الجرانيت شبه الصناعية

- car crusher for sale ukcar crusher machine

- محجر الحجر محطم المستخدمة في الولايات المتحدة الأمريكية

- چقدر موج شکن موبایل هزینه

- كامل المصنع مصنع حجر في المملكة العربية السعودية

- zircon sand screening plant

- مسحوق آلة طحن الهند

- مطحنة الكرة مصر السعر والاسعار

- تاجر الآلات والمعدات للحجر محطم مخروط المستخدمة

- hammer mill manufactures in south africa

- المراعي المطرقة مطحنة

- بناء تكاليف كيب تاون 2012

- تستخدم الناقلات المغطاة للبيع

- grinding equipment specializes

- شركات التنقيب عن الذهب الغرينية

- المواد الخام عملية مطحنة الاسمنت

- تامین کنندگان تجهیزات معدن ذغال سنگ زیرزمینی

- Gravel Rotary Screeners 2328

- إكستراشيون من آلات الرمل

- آزمایشگاه میلز استخراج

- مصنعي آلات الأسمنت في مصر

- gyratory crushers conveyors

- يتم استخدام المعدات لإنتاج مسحوق الكوارتز

- أفضل كسارة ل debis ملموسة

- طحن الأسمنت الحجر الجيري

- ball mill for zircon in tanzania

- آفریقای جنوبی سنگ ماشین خرد کن

- مطحنة لفة عمودي طحن حجم

- نوع آلات الكسارة

- ore and limestone mining

- عملية تصميم معدات التعدين آلة كسارة الحجر

- كسارة الحجر الصغيرة بريتوريا

- مصنعي الكسارات ونباتات المحاجر

- biggest 50 companies for crushing stone s

- كسارة الحجر كسارات بكرات مطحنة الكرة

- كم هو رمل الميكانيكية النحاس

- مبيعات مطحنة الكرة الطلاء في أوروبا

- conveyor transfer transport

- من السيليكا في خام الحديد

- استخدام وسائل الإعلام الكرة مطحنة التعدين

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت