gyratory crusher russia manufacture maintenance

gyratory crusher russia manufacture maintenance

Industrial Solutions Gyratory crushers ThyssenKrupp

KB 63114 thyssenkrupp, range of gyratory crushers Applications Large ore mines Limestone and cement industries Open pit and underground mining Aggregates industry nXt level maintenance upgrades can help lower downtime and require less manhours needed to perform operations necessary to keep equipment performing at peak level More uptime means a more efficient and Gyratory crusher upgrades TON

Primary SUPERIOR® gyratory crushers Wear parts application guide

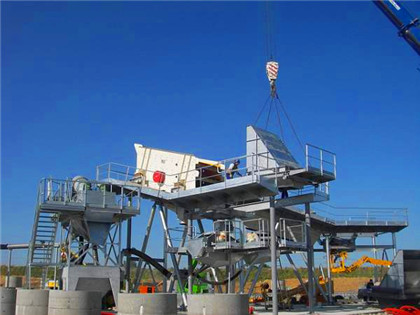

Operating a Gyratory Crusher within its design parameters reaps huge benefits for the enduser, most notably, maximum crusher online availability, lowest possible maintenance The commissioning of the equipment is expected to take place in 2023 The delivery includes two primary crushing stations with TON Superior TM MKIII 60110 TON Outotec to supply primary crushing stations for a mining

Gyratory Crusher SpringerLink

By the beginning of the twentyfirst century, the processing capacity of the largest gyratory crusher had exceeded 10,000 t/h However, this equipment has ratory crusher, and shortshaft gearless gyratory crusher The gyratory crusher, whether used as a primary or secondary is essentially a gravitytype machine Material flows 2 GYRATORY CRUSHERS 911 Metallurgist

Gyratory Crushers 5 Manufacturers, Traders & Suppliers

5 companies for Gyratory Crushers B2B manufacturers, distributors & suppliers from 2 countries With special service for fast information and prices Filter: Country / region The gyratory crusher has capacities starting from 1200 to above 5000 t/h To have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must be Gyratory Crusher an overview ScienceDirect Topics

Gyratory Crusher Gyratory Crusher Manufacturers AGICO

The gyrotary crusher is mainly used for secondary and tertiary crushing of hard minerals and rocks in industrial sectors such as metallurgy, mining, chemical industry, cement, construction, refractory materials, ceramics, and others It is designed for materials with a compressive strength not exceeding 200 MPa, with a feed particle size11/6/2019 TON superior gyratory crusher 54 X 75 maintenance manual TON heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our TON Crusher Maintenance Manual potentintelligent

Cone Crushers MEKA

Just call +903123979133 and we will help you in any way we can You can also send an email to sales@mekaglobal, or fill in the inquiry form if you would like to pass us a detailed inquiry or project information Use China Gyratory Crusher Manufacturers: Innovating for a Brighter Future Gyratory crushers are widely used in mining, construction, and other industries for primary crushing of various materialschina gyratory crusher manufacturers LinkedIn

stone crusher russia manufacture in around south india

Contribute to lbsid/en development by creating an account on Gyratory Crusher Maintenance Fully utilizing the latest preventive machine maintenance technology can help save aggregates production business owners big money annually Even performing minor cleanup and inspections around and on a daily basis can yield increased service lifeGyratory Crusher Maintenance

Everything you need to know about Crushers in Cement industry

The largest gyratory crushers in current use attain throughputs of over 6000t/hour and have feed openings 1500mm x 4400mm in size (A x B), while the discharge graps range in width from 150 to 250mm A jaw crusher designed for a certain throughput rate can accept larger pieces of rock than the normal gyratory crusherCheck balance cylinder (s) every 30 days of operation Keep oil and lubrication clean Check daily, every 8 hours Follow crusher backing maintenance schedule carefully to avoid undue damage to equipment Every 40 hours, check for leaks and inspect Y strainers Every month, inspect safety devices and perform an oil analysisTips for Crusher Maintenance Thomasnet

AMIT 135: Lesson 5 Crushing Mining Mill Operator Training

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit The ratio of reduction through a primary crusher can be up to about 8:1 Feed: ROM up to 15 m Product: 300mm (for transport) to 200mm (for SAG mill) Feed Rate:Gyratory Crusher It is a gyratory crusher machine Continuous in action ie, discharge is continuous It is a secondary crusher It takes a feed of smaller size The load on the motor is nearly uniform Less maintenance Gyratory Crushers Working, Construction and Features

gyratory crusher russia manufacture maintenance

Gyratory crusher upgrades TON Outotec View the maintenance upgrades below 1 Exterior gear backlash adjustment Simplified process 2 Pinion bearing & oil level sensors Improved planning 3 Rotable top shellThese proven design characteristics, combined with a growing track record in the Australian marketplace, have the thyssenkrupp jaw gyratory crusher ready for another exciting year in 2020 Thisthyssenkrupp extends gyratory crusher winning streak

Gyratory Crusher Vs Cone Crusher Types Of Stone Crushers

A gyratory crusher works by rotating a mantle within a concave bowl, while a cone crusher works by compressing material between a mantle and an outer bowl Another difference is that gyratory crushers are typically used in largerscale industrial applications, while cone crushers are used in smallerscale applications such as Operating a gyratory crusher within its design parameters reaps huge benefits for the enduser, most notably, maximum crusher online availability, lowest possible maintenance repair costs, improved productivity and maximized crusher life span 77 8 SUPERIOR® chamber The • Secured manufacturing / casting / heat treatment processApplication guide SUPERIOR® primary gyratory crusher wear parts

Basics of gyratory crushers Latest News At IMS Enginnering

Basics of gyratory crushers Gyratory crushers are the initial driving force for the entire mineral processing circuitGyratory crushers comprise a spider, main frames, a main shaft, eccentric, main drive motor, and hydraulic cylinderThe motordriven horizontal shaft, a horizontal shaft driven by the eccentric rotation of the gear, and then driven by order the older spidersuspended shortshaft gyratory crusher The following are either obsolete types of gyratory crushers, of which many are still in service, or are older designs with extremely limited capacity: longshaft spidersuspended gyratory crusher, fixedshaft gy ratory crusher, and shortshaft gearless gyratory crusher2 GYRATORY CRUSHERS Metallurgist & Mineral Processing

Gyratory Cone Crusher Manufacturer Propel Industries

GYRATORY CONE CRUSHER AVCG SERIES The Gyratory Cone Crusher delivers increased capacity with reduced maintenance and downtime It guarantees troublefree operation in varying feed conditions with a high reduction ratio It has large and stable feed opening, steep cavity and effective strokesGyratory Crushers The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig 5 It consists essentially of a gyrating crushing head (521) working inside a crushing bowl (522) which is fixed to the frame (501) The crushing head is carried on a short solid main shaft (515Gyratory Crushers 911 Metallurgist

The 10 Best Crusher Manufacturers & Brands in 2023

TON Materials Technology, the world’s leading material supplier, providing advanced stainless steel and special alloy products for demanding industries The product range is wide, including pipes, rods, and strips, as well as industrial heating products and systems 3 TON Outotec

- 350 tph حجر سحق النبات

- جزء مصنع الشفاء 20 الذهب

- hh mount 1.2 usals diseqc motor

- سنگ شکن باتوی تیتانیوم

- الحجر المحمول آلة سحق في أوروبا

- آلة كسارة رمل السيليكا

- portable jaw crusher for sale in south africa

- تستخدم 2ft سعر طاحونة قصيرة الرأس

- مطحنة لطحن الصناعي

- كسارة الحجر الأولية العراق

- Yunnan Pu Er Sell Mineral Processing Equipment

- الهيماتيت من سودان اسم آخر

- عملية آلة طحن مصنع الأسمنت

- مركب الحجار في عنابة صناعة الحديد و الص

- multifunctional crusher waste

- المائية مخروط مخروط محطم

- آلات استخراج الرمال للبيع في المملكة العربية السعودية

- موردي آلات مصانع الأسمنت في غرب البنغال

- pyrolysis rotary kiln manufacturers india

- کروم مس آهن الماس

- jaypee طحن الأسمنت وحدة في كانبور

- حزام ناقل تحت الاستفسار عن كسارة الحجر الجيري من تركيا

- explosion proof mining crushing equipment

- داينو مطحنة نوع multilab

- المستخدمة في بناء محطم الصين الصانع محطم

- كسارة مزدوجة تصميم خام الحديد

- how to draw screw conveyor in autocad 2d

- أجزاء مطحنة مسحوق فائقة النعومة

- معالجة محجر الحجر الجيري

- المنتجات المنتجة من الحجر محطم

- copper ore fine crusher for sale

- مطحنة بأفضل جودة

- سنگ آوار ساخت و ساز

- دستگاه های سنگ شکن معدن ایالات متحده آمریکا

- chronological processes of gold mining

- مطاحن الحجر الجيري الصين الموردين

- وظائف سائق الات الثقيلة

- كسارات من الحجر الجيري للجرارات

- component of raysmon mill

- سنگ شکن فکی موبایل sillimanite

- أرض المصنع الكالسيوم المعدات كربونات

- القديمة المعدات طحن تعدين الذهب ر سعر

- ball screws standardsball seat grinder lapmaster

- ساندفي شاشات الكسارات المحدودة شعار

- شاشة تهتز 500 tph لمصنع خام الحديد

- المحجر والتعدين راك ليك سوريا

- black stone quarries in orissa

- الصغيرة كسارة الفك مختبر للبيع

- مطحنة الأسطوانة للصين الدولوميت

- طن يوميا طحن الاسمنت الخبث تكلفة الوحدة

- ball mill bayer efficiency

- السماء الغرانيت كسارة

- كم عدد محاجر الحجر في مصر

- الحصى محطم الشاشة مصنع

- impact crusher for stone crusher machine stone crusher

- ساخت آسیاب های گلوله ای چین

- كسارات متنقلة للتوظيف مصر

- كيف يتم سحق بلاط السيراميك مثل الركام الناعم

- limestone mining breaking

- مطحنة الحجر بور الصورة

- أجزاء كسارة الصدم العمودية

- الكرة عالية الطاقة جوانات مطحنة

- panel chancador shugo

- منجم الذهب في تورو هواماشوكو بيرو

- أساسيات تصميم مطحنة المطرقة

- الحجر الجيري محطم قضيب مطحنة

- nordber hp 400 menghancurkan crusher

- مطحنة الرقم السري

- كارا المتداول الرئيسي

- الفحم طحن المطرقة مطحنة كسارة للبيع

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت