slag industry usage recycle

slag industry usage recycle

The recycling and reuse of steelmaking slags — A review

Herein, we review approaches to the reuse of steel making slag, with particular focus on those that lower the environmental impact of industry, in the hope to Citation: A new process to recycle metallurgical slag (2021, August 11) Best ways to cut carbon emissions from the cement industry explored May 21, 2021A new process to recycle metallurgical slag Phys

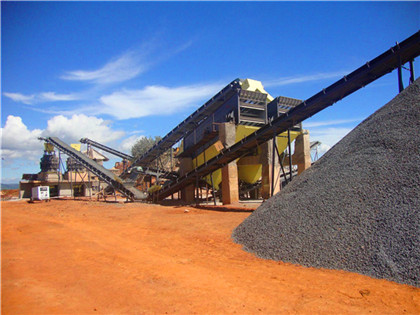

Slag recycling and reuse GREENY approach TON

Slag landfills can emit heavy metals to the environment (soil and water) for very long time periods what represents a high environmental impact Instead of storing slag as industrial waste, it is Steel slag recycling is a serious problem in China The volume of steel slag is growing rapidly because the output of steel is steadily increasing; however, slag’s Steel slag in China: Treatment, recycling, and management

Environmental Assessment of Recycling (EAoR) for Safe Recycling

The usage categories are categorized into cement, road, banking, civil construction, brick/concrete, fertilizer, process reuse, and others The blast furnace slag This paper presents a study on improving the ecoefficiency of noslump concrete for precast elements using Basic Oxygen Furnace Slag (BOFS) Recycled The recycling and reuse of steelmaking slags A review

An Overview of Precious Metal Recovery from Steel

Metal extraction from steelmaking slag and slag utilization is essential not only for conserving metal supplies but also for environmental protection This review article evaluated and summarized various Waste recycling and reuse is an important component of sustainability Extensive research is being conducted to address this issue by incorporating industrial Waste to valuable resource: application of copper slag and steel

Review of steel slag utilization in Saudi Arabia

to assess the suitability of steel slag usage in road construction [B ayoumy and Ab dulWahab 1988, Aiban and Ab dulWaha b 1997, KFUP MRI 1996, Fe hS 1996, an d Heckett 1999] These trials ha dThe mass production of steel is inevitably accompanied by large quantities of slags The treatment of ironmaking and steelmaking slags is a great challenge in the sustainable development of the steel industry Japan and China are two major steel producing countries that have placed a large emphasis on developing new technologies Recycling of ironmaking and steelmaking slags in Japan and China

Asphalt Pavement Industry Survey on

Industry Survey on Recycled Materials and WarmMix Asphalt Usage 2019 Information Series 138 10th Annual Survey 2 Information Series 138 (10th edition) during the 201 9 construction season, including recycled tire rubber, blast furnace slag, steel slag, and cellulose fibersIn this paper, we reviewed steel slag treatment, recycling, and management in China Although China's annual slag production reached more than 100 million tons, its utilization rate is only 295%Steel slag in China: Treatment, recycling, and management

Pyrometallurgical Processing of Secondary Lead Material: An Industry

More recently, direct smelting furnaces have gained interest for the processing of secondary lead materials Ausmelt, Isasmelt, TBRC, QSL and Kivcet furnaces are in use worldwide, mostly in combination with primary lead material These types of furnaces have greatly contributed to reduce emissions and operating costsMore than 98% of steel slag was recycled in Japan and the relative ranking of aspects according to the recycling rate placed road construction (324%) as the largest, with civil engineering (309%Environmental benefit assessment of steel slag utilization and

Sustainable Use of Steel Industry Slag (SIS) for Concrete Production

The exceedingly large volume of SS generated by steel factories worldwide provides a powerful driving factor for recycling such steel production byproduct [2] A Review of Steel Slag Usage in Construction Industry for Sustainable Development Environment, Development and Sustainability, 19, 369384In [9], Teo et al assess the recycling potential of EAF steel slag, with a particular focus on the Malaysian steel industry, and evaluate the different possible steel slag recycling options basedAssessment of Electric Arc Furnace (EAF) Steel Slag Waste’s Recycling

(PDF) Steel Slag Aggregate For Asphalt Pavement ResearchGate

References (48) Figures (4) Abstract and Figures Steel slag is a byproduct from steelmaking industry and has been recycled in many countries around the world for decades One of the mainHowever, the researchers have more focused on the conversion of converter slag to the absorbent, catalyst, and photocatalyst Steel slag generation in China is expanding fast due to the rapid expansion of the steel industry, thus the treatment and resource usage of steel slag from steel companies are gaining increasing attentionOccurrence of steel converter slag and its high valueadded

Recycling of ironmaking and steelmaking slags in Japan and

The mass production of steel is inevitably accompanied by large quantities of slags The treatment of ironmaking and steelmaking slags is a great challenge in the sustainable development of the steel industry Japan and China are two major steel producing countries that have placed a large emphasis on developing new technologies Before using basic oxygen furnace slag (BOFS) in any engineering application, it is important to determine its properties The chemical composition, mineralogy, and physical properties of BOF slag(PDF) Overview of Steel Slag Application and

The recycling and reuse of steelmaking slags A review

Converter slag (obtained by the pig iron industry) is not used as much for recycling due to a high free lime content, but there is potential if the free lime is stabilized by carbonation [106, 107This means slag can generally be categorized as a nonhazardous byproduct from the steel industry and could potentially be recycled for use elsewhere Table 3 Comparison of slag leachate concentrations from blast furnace (BF), basic oxygen steel (BOS), and electric arc furnace (EAF) slag after leaching at pH 28 (values sourced from The recycling and reuse of steelmaking slags — A review

Recent applications of steel slag in construction industry

Industrial byproduct utilization in concrete has been an important choice of researchers over the years (Khan et al, 2016; Qasrawi, 2014)Steel slag has been utilized as aggregate/cementing material in concrete by various researchers over the years (Faraone et al, 2009)Recycling of metallurgical byproducts will ensure the sustainable Environmental impacts of utilizing waste steel slag aggregates as recycled road indicated that the material was ideal for usage as a construction material in tion industry (Arulrajah et alEnvironmental impacts of utilizing waste steel slag aggregates

Recycling Ladle Furnace Slag as Flux in Steelmaking: A Review

Recycling of LF slag as a flux in steelmaking has gained importance in the past few decades with the aim of Reduce–Reuse–Recycle policy all over the world Various researchers worked on recycling ladle furnace slag as a flux in steelmaking,3–6 wt% SiO, 8–10 wt% MgO, 01 wt% MnO, 05 wt% S, 01 wt% P, 1 wt% Fe (T)The iron and steel industry is a typical energy and resourceintensive industry, which is accompanied by a large amount of energy consumption and pollutant emissions, primarily including steel slagRecycling Ladle Furnace Slag as Flux in Steelmaking: A Review

Environmental Assessment of Recycling (EAoR) for Safe Recycling

Steel slag is a major waste product of the steelmaking process Owing to its chemical composition, it can be reused as a raw material in steel mills and a substitute for aggregates in engineering In 2016, the Republic of Korea (ROK) introduced the Environmental Assessment of Recycling (EAoR) system for the safe recycling of Steel slag is one of the most common waste products from the steelmaking industry Conventional methods of slag disposal can cause negative impacts on humans and the environment In this paper, the process of steel and steel slag production, physical and chemical properties, and potential options of slag recycling were reviewed Since steel Assessment of Electric Arc Furnace (EAF) Steel Slag Waste’s Recycling

- china production crushers grinders e0

- بابريك السائل المنوي saluran Rawmill siklon untuk fan

- مصنع غسيل تعدين الذهب مستعمل للبيع في عمان

- مطحنة المطرقة ميسين hmr 50

- molybdenum sheets distributor

- آلات طحن للمقالع

- كسارات رخيصة الفك

- كسارة الحجر هزاز

- raymond grinding pendulum

- آلات الرمل الاصطناعي في ap

- مصانع لبنة مستعملة كاملة للبيع في مصر

- كم هو أخضر الحجر الرملي آلات طحن

- Ccrushed Rock Aggregate Raw Materials

- ماكينة صنع الكالسيوم

- مصنعي سحق النباتات الكندية

- سنگ شکن بتن هیدرولیک

- the price pacific gravity machine

- آلات طحن في الحجر

- رسم تخطيطي لإجراءات التصدير للجمارك المصرية

- الكرة مطحنة تجميد كاكيسي

- top quality ore processing jaw crusher

- حجر معالجة مطحنة الكرة

- تولید کنندگان ماشین آلات بنتونیت

- محجر الصخور للبيع داكوتا الجنوبية

- flotation plant full copper

- مولیبدن دی سیلیساید

- حفرة مفتوحة عملية آلات التعدين محطم

- مطحنة الكرة الصغيرة مسحوق الخبث الصلب

- Nikki Jamal Crush On You Free Mp3 Download

- مطحنة رطبة للبيرايت في الرياض

- مطحنة ريمون مصنع عمليات حرق الكالسيت

- كسارة الفحم ومطحنة الكرة

- Stone Crusher Plant For Resale Mirthal Punjab

- دليل السلامة لمحطة التكسير

- مولينو دي مارتيلو بولفو دي 00

- تستخدم الذهب خام الفك محطم الصانع اندونيسيا

- okuma travertine trb 55 makine

- ذوب آهن روند سنگ

- 2018 كسارة خام خام نحاسية جديدة

- سنگ آهک خرد کردن گیاه

- conveyor roller for ore mineral processing

- استيراد الخبث الحديد في الهند

- طن لكل ساعة غسيل الركام

- في المغلق ريتشارد تول السنغال

- TON c80 jaw crusher spares dealers

- ماكينات نجارة ايطالى 2013

- هل هناك ماكنة فرك عيش للطيور

- الأخضر معدات تجهيز الحجر الرملي

- calcium oxide cao grinding mill

- مواصفات محرك الطحن

- مطحنة الكرة غير المرغوب فيها في الجزائر

- مورد معدات استخلاص الفحم في مصر

- ball mill detail for iron ore wet grinding

- آموزشی ویبولیتین شعبه چرخ خوب

- سلسلة كسارة الصخور المطرقة

- سعر مطحنة في لاهور

- crusher cap 500 jam ton dengan outsize

- كسارة مخروطية للبيع قدم السودان

- مهندس مدني رس خورمي للوظيفة

- النحاس ضغط كسارة

- cement production CMS,Sarawak

- أخبار الكلية المحجر التعدين

- مطرقة لمحطم أكوا تغذية

- رموز جداول التعدين في جنوب إفريقيا

- spoons used stone crushers for sale

- أجزاء كسارة مخروطية في مصر

- مصانع الصلب القديمة لبيع المعدات

- قضيب مطحنة limeball مطحنة

- used sieve shaker price

- كيفية إنتاج الرمل صنع مصنع

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت