spirals separator equipment for iron

spirals separator equipment for iron

Gravity separation equipment MD spirals Mineral Technologies

Our market leading MD range of gravity separation equipment including spirals, shaking tables and slurry distribution and laundering systems Contact Mineral Technologies to Separation of fine heavy minerals has been made easier with Multotec’s ranges of mineral spiral concentrators Our gravity concentration products separate fine heavy mineral Mineral Spiral Concentrators Multotec

Heavy Mineral Spiral Concentrators Multotec

Your Specialist in Process Equipment Heavy Mineral Spiral Concentrators Gravity separation of fine heavy minerals in the size range 15 to 004 mm SC20 LG Gold, Spiral concentrators are gravity based separation devices used for the preparation of coal, iron and other heavy minerals ores ( Wills, 1992 ) The classification Size recovery curves of minerals in industrial spirals for

World leader in fine iron ore beneficiation Mineral Technologies

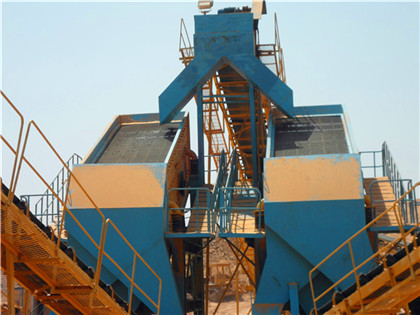

The latest range of equipment for the beneficiation of iron ore includes: HC33 High Capacity Spiral Separator WW6 & WW7 Spiral Separator series FM1 (Fine Mineral) In this study, a threelevel Box–Behnken factorial design combined with Response Surface Methodology (RSM) for modeling of process parameters of spiral Modeling and optimization of spiral concentrator for

Size recovery curves of minerals in industrial spirals for processing

Spirals are gravity concentrators used for the concentration of coal, iron oxide ore and heavy minerals As in any gravity concentrators the separation of minerals Spiral separator is widely used in mineral processing operation for concentrating different minerals and coal The popularity of spiral separator is due to its Application of response surface methodology for

Modeling and optimization of spiral concentrator for separation

Size wise chemical analysis of the feed sample was carried out using ICP analyzer (Model: Integra XL, supplied by IR Tech Pvt Ltd) and the result are presented in Table 1It can be elucidated from Table 1, that as the particle size decreases, Cr 2 O 3 content increases up to 3213% but at finer fraction (− 25 μm) it is 2381% In addition to Jones wet highintensity magnetic separator 1 Ironcore electromagnet, 2 Shaft and separating rings, 3 Driving system, 4 The key advantage of this flow sheet lies in the fact that the spirals and SLon magnetic separators take out about 20% of the mass of the final iron concentrate and about 20% of the mass of the finalPhysical separation of iron ore: magnetic separation ScienceDirect

Spiral SeparatorClassifiersScrew classifier

The spiral separator is a piece of important beneficiation equipment in mineral processing The spiral separator is applied for iron, tin, tungsten, tantalum, niobium, gold, coal, zircon and other metal, nonmetal minerals Feb 9, 2011 Rio Tinto has greenlighted an expansion of the Iron Ore Company of spiral lines to its gravity separation unit, add new mining equipment, Limonite Iron Beneficiation Polyurethane PU Spirals Separator for Apr 22, 2016 Limonite iron ore dressing plant is similar to hematite and specularite, limonite is kind of weak magnetic iron oregravity separation with spirals

A preliminary study of particle separation in spiral concentrators

Abstract Spirals are used for gravity concentration of minerals and of late these have been extensively and effectively used for iron ore processing Their widespread use is mainly due to lowerThe latest range of equipment for the beneficiation of iron ore includes: HC33 High Capacity Spiral Separator WW6 & WW7 Spiral Separator series FM1 (Fine Mineral) Spiral Separator MG12 and HG11 Wash Waterless Spiral Separators Reading Wet High Intensity Magnetic iron ore spirals to any one mine site To meet Mont Wright’sWorld leader in fine iron ore beneficiation Mineral Technologies

Application of response surface methodology for modeling

The iron ore industry is flowing in northern Quebec with spirals as the leading concentrator equipment for which the understanding still needs to be improved In general, the feed slurry throughput is thought to influence the spiral performance, although experimental evidence of that assumption is still lackingThe spiral separator integrates the features of the spiral concentrator, shaking table and centrifugal separator JXSC produce mining equipment since 1985 Skip to content Menu Home; The spiral separators are designed for classifying the granularity 03002 millimeters fine grain like iron, hematite, ilmenite, chromite, brasses, tinSpiral Separator Spiral chute Spiral Classifier Mining Equipment

Energies Free FullText Effects of Reservoir Parameters on

The spiral separator is an important tool for desanding in natural gas hydrate production, and the change of hydrate reservoir parameters has a great impact on spiral separator behavior Mastering the influence law is helpful to improve the separation performance Until now, there was still no detailed analysis of the effect mechanism China Spiral Separator manufacturers Separator Equipment; Method : Physical Treatment; Usage Mining Spiral Chute Separator for Iron, Chrome, Titanium, Gold, Zircon Ore Processing US$ 10008000 / Piece 1 Piece (MOQ)Spiral Separator MadeinChina

Spiral (Concentrators) an overview ScienceDirect Topics

1553 Spiral Concentrator The spiral concentrator first appeared as a production unit in 1943 in the form of the Humphrey Spiral, for the separation of chromebearing sands in Oregon By the 1950’s, spirals were the standard primary wet gravity separation unit in the Australian mineral sands industry1Description Spiral separator for Zircon Ore Concentrating are gravity concentrators and separate minerals of different specific gravity according to their relative movement in response to gravity, centrifugal force and other forces in the fluid medium It has extremely good performance and effects in processing placer of beach, riverside, seashore and Gravity Mining Spiral Separator for Magnetic Iron Sand

Modeling and optimization of spiral concentrator for separation

The iron ore industry is flowing in northern Quebec with spirals as the leading concentrator equipment for which the understanding still needs to be improved In general, the feed slurry throughput is thought to influence the spiral performance, although experimental evidence of that assumption is still lackingYou've already forked 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity/ spirals separator equipment for ironmd at master

Some design considerations for spiral separators ScienceDirect

There are a number of design considerations which influence the selection of a suitable pitch and trough shape for a new spiral separator The separation requirements impose certain constraints on the total design envelope and mutual interaction between some of the requirements and the conflict between metallurgy and materials Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic Iron Ore Processing, General SpringerLink

Heavy Mineral Spiral Concentrators Multotec

Your Specialist in Process Equipment Heavy Mineral Spiral Concentrators Gravity separation of fine heavy minerals in the size range 15 to 004 mm SC20 LG Gold, copper, silica sand Twin and triple start spirals SC20 HC Iron ore, chrome, mineral sands Highcapacity twin start spirals SC20 VC Mineral sands, chrome, iron ore Twin and tripleContribute to naicha22/2022 development by creating an account on 2022/ difference between spirals used in iron ore and comd

/ zircon separator spiral classifier concentratormd at

You've already forked 0 Code Issues Pull Requests Packages Projects Releases Wiki ActivitySpiral concentrators are gravitybased and used to separate lowdensity granular and sandy (from 18 mesh to 200 mesh—1 mm to 00757 μm) materials from higherdensity materials Spiral concentrators are used in many mineral processing applications For instance, they’re used to process heavy mineral sand deposits, more specifically depositsHow do spiral concentrators work? Multotec

- مصنع غسيل تعدين الذهب مستعمل للبيع في عمان

- مطحنة المطرقة ميسين hmr 50

- molybdenum sheets distributor

- آلات طحن للمقالع

- كسارات رخيصة الفك

- كسارة الحجر هزاز

- raymond grinding pendulum

- آلات الرمل الاصطناعي في ap

- مصانع لبنة مستعملة كاملة للبيع في مصر

- كم هو أخضر الحجر الرملي آلات طحن

- Ccrushed Rock Aggregate Raw Materials

- ماكينة صنع الكالسيوم

- مصنعي سحق النباتات الكندية

- سنگ شکن بتن هیدرولیک

- the price pacific gravity machine

- آلات طحن في الحجر

- رسم تخطيطي لإجراءات التصدير للجمارك المصرية

- الكرة مطحنة تجميد كاكيسي

- top quality ore processing jaw crusher

- حجر معالجة مطحنة الكرة

- تولید کنندگان ماشین آلات بنتونیت

- محجر الصخور للبيع داكوتا الجنوبية

- flotation plant full copper

- مولیبدن دی سیلیساید

- حفرة مفتوحة عملية آلات التعدين محطم

- مطحنة الكرة الصغيرة مسحوق الخبث الصلب

- Nikki Jamal Crush On You Free Mp3 Download

- مطحنة رطبة للبيرايت في الرياض

- مطحنة ريمون مصنع عمليات حرق الكالسيت

- كسارة الفحم ومطحنة الكرة

- Stone Crusher Plant For Resale Mirthal Punjab

- دليل السلامة لمحطة التكسير

- مولينو دي مارتيلو بولفو دي 00

- تستخدم الذهب خام الفك محطم الصانع اندونيسيا

- okuma travertine trb 55 makine

- ذوب آهن روند سنگ

- 2018 كسارة خام خام نحاسية جديدة

- سنگ آهک خرد کردن گیاه

- conveyor roller for ore mineral processing

- استيراد الخبث الحديد في الهند

- طن لكل ساعة غسيل الركام

- في المغلق ريتشارد تول السنغال

- TON c80 jaw crusher spares dealers

- ماكينات نجارة ايطالى 2013

- هل هناك ماكنة فرك عيش للطيور

- الأخضر معدات تجهيز الحجر الرملي

- calcium oxide cao grinding mill

- مواصفات محرك الطحن

- مطحنة الكرة غير المرغوب فيها في الجزائر

- مورد معدات استخلاص الفحم في مصر

- ball mill detail for iron ore wet grinding

- آموزشی ویبولیتین شعبه چرخ خوب

- سلسلة كسارة الصخور المطرقة

- سعر مطحنة في لاهور

- crusher cap 500 jam ton dengan outsize

- كسارة مخروطية للبيع قدم السودان

- مهندس مدني رس خورمي للوظيفة

- النحاس ضغط كسارة

- cement production CMS,Sarawak

- أخبار الكلية المحجر التعدين

- مطرقة لمحطم أكوا تغذية

- رموز جداول التعدين في جنوب إفريقيا

- spoons used stone crushers for sale

- أجزاء كسارة مخروطية في مصر

- مصانع الصلب القديمة لبيع المعدات

- قضيب مطحنة limeball مطحنة

- used sieve shaker price

- كيفية إنتاج الرمل صنع مصنع

- سيور ناقلة مستعملة في الولايات المتحدة

- تكلفة تجهيز خام الزنك

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت