manganese ore concentrates uses

manganese ore concentrates uses

Manganese

Manganese is a chemical element with the symbol Mn and atomic number 25 It is a hard, brittle, silvery metal, often found in minerals in combination with iron Manganese is a transition metal with a multifaceted array of industrial alloy uses, particularly in stainless steels It improves strength, workability, and resistance to wear Manganese oxide is used as an oxidising agent; as a rubber additive; aMANGANESE (Data in thousand metric tons gross weight unless otherwise noted) Domestic Production and Use: Manganese ore containing 20% or more manganese has not been Manganese Data Sheet Mineral Commodity Summaries 2020

Manganese Ore an overview ScienceDirect Topics

537 Manganese Ore Manganese ore is required in iron making to control the manganese content of the hot metal in the desired range Unlike other plants, where manganese ore Ores and concentrates: Containing less than 47% manganese Containing 47% or more of manganese Manganese dioxide Highcarbon ferromanganese Ferrosilicon manganese Mineral Commodity Summaries 2022 Manganese USGS

Metals Free FullText Extraction of Manganese and

Sampling The coarse manganese concentrate with Mn grade of 2863% and Fe grade of 1865% was obtained from a high ironbearing manganese carbonate ore in Tongren, China by spiral chute Manganese is the 12th most abundant element in Earth’s crust Its concentration varies among common types of rocks, mostly in the range of from 01 to 02 percent The Manganese USGS Publications Warehouse

Manganese Element information, properties and uses

Manganese(IV) oxide is used as a catalyst, a rubber additive and to decolourise glass that is coloured green by iron impurities Manganese sulfate is used to make a fungicide It has been demonstrated that manganese concentrate can be used for manganese smelting and for teels with low content of phosphorus, and that allows reducing import of manganese materialsTechnology for producing highquality manganese

Virginia Energy Geology and Mineral Resources Manganese

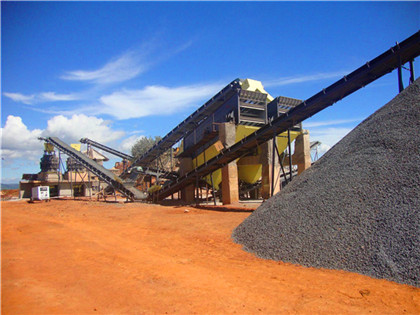

According to Ladd and Stead (1944), five cars of ore were shipped in the first year of production, followed by over 16 thousand tons of 35 percent manganese concentrate between 1918 and 1940 Although the site was considered largely mined out by the early 1940s, the US Bureau of Mines assessed the site to determine how much recoverable The complete processing flow of manganese ore mainly includes five steps: crushing, washing, grinding, dressing, and drying Next, I will introduce the detailed manganese ore processing production line to you 1 Manganese ore crushing process and equipment Manganese ore crushing is the first step in the process, which involves 5 Easy but Efficient Steps to Realize Manganese Ore Processing

Metals Free FullText Extraction of Manganese and

In this research, the coarse manganese concentrate was collected from a manganese ore concentrator in Tongren of China, and the contents of manganese and iron in coarse manganese concentrate manganese processing, preparation of the ore for use in various products Manganese (Mn) is a hard, silvery white metal with a melting point of 1,244 °C (2,271 °F) Ordinarily too brittle to be of structural value itself, it is an essential agent in steelmaking, in which it removes impurities such as sulfur and oxygen and adds important physical properties to Manganese processing Extraction, Uses & Benefits Britannica

IS 1473 (2004): Methods of Chemical Analysis of Manganese Ores

for determination of silica, barium oxide, manganese, iron, phosphorus, sulphur, alumina and other elements in manganese ores and concentrates The atomic absorption method can be used for the determination of Si, Al, Ti, Fe, Ca, Mg, Cu, Pb, Zn, Co, Cr, V, Ba and K, in the following ranges and composition: Si02 025 percent to 25 percentMagnetic separation is often considered pertinent for manganese ore beneficiation when the ore is abundant with siliceous rich gangue mineral phases However, the process is deemed to be inapposite for the ferruginous type of ore, and remains a grey area of research In the present investigation, two different types of manganese ore Minerals Free FullText Influence of Mineralogy on the Dry

Manganese Ore Geoscience Australia

Since its first ore shipment in 2006 25, the project has progressively mined these deposits for manganese ore to feed its 1 Mtperannum plant for the production of manganese concentrate The company anticipates that mining activity for 2019–2020 will continue at mines planned in selected areas of the Chugga Far North, Tourag and Yaka 2 Manganese Extractive Metallurgy The process of extracting a metal from its ore and refining it is called metallurgical process or simply as metallurgy Metallurgical processing of an ore include: concentration of the ore, conversion of concentrate to Hydrometallurgical Processing of Manganese Ores: A Review

Study on the Gravity Processing of Manganese Ores

Manganese ores and concentrates are purified by several methods6 Now a da ys, few mang anese oper ations in some milling plants ar e mor e complicated than washing, screening, jigs, tables and in a f ew instances, flotation Now it is not only necessary to increase the manganese content, but also to decrease the2601 Iron ores and concentrates, including roasted iron pyrites Iron ores and concentrates, other than 260120 Roasted iron pyrites 2602 260200 Manganese ores and concentrates, including ferruginous manganese ores and concentrates with a manganese content of 20 % or more, calculated on the dry weight 2603 260300 Ores, slag and ash World Customs Organization

Improve your manganese ore grade • STEINERT

The 75mm + 10mm fraction reports to an Ore Sorter, the 10mm + 10mm reports to a heavy media cyclone, and the 10mm is delivered to tailings dam or depending on the grade of the ore and manganese distribution maybe processed further to make a very fine manganese concentrate by methods such as hydraulic classification, gravity Domestic Production and Use: Manganese ore containing 20% or more manganese has not been produced domestically since 1970 Ores and concentrates 2602000040/60 Free Manganese dioxide 2820100000 47% ad val Highcarbon ferromanganese 7202115000 15% ad valManganese Data Sheet Mineral Commodity Summaries 2020

Manganese ores and concentrates, including manganiferous iron ores

Manganese ores and concentrates, including manganiferous iron ores and concentrates with a manganese content of 20% or more, calculated on the dry weight: 2019: World: 99498 Spain: Export: : Manganese ores and concentrates, including manganiferous iron ores and concentrates with a manganese content of 20% or more, Manganese ores and concentrates 1 3 1 1 1 Ferromanganese 9 10 5 5 11 Silicomanganese 8 4 2 2 4 Shipments from Government stockpile:2 Manganese ore — — — — 2 Ferromanganese and manganese metal, electrolytic 12 13 10 54 17 Consumption, reported: Manganese ore3 378 369 442 378 390Mineral Commodity Summaries 2022 Manganese USGS

Mineralogical Characterization of Manganese Oxide Minerals

The Guangxi Zhuang Autonomous Region is an important manganese ore district in Southwest China, with manganese ore resource reserves accounting for 23% of the total manganese ore resource reserves in China The Xialei manganese deposit (Daxin County, Guangxi) is the first superlarge manganese deposit discovered in China The The data from laboratory test clearly illustrate that there are the possibilities to produced manganese concentrates with up 300% Mn content from low grade manganese ore by deposit of Bosna andSTUDIES AND POSSIBILITIES OF LOW GRADE MANGANESE ORE BENEFICIATION

Synergistic effect of reduction leaching of manganese anode slime

The oxidation of manganese anode slime is used to pretreat refractory gold ores The combined leaching of manganese anode slime and gold concentrate can simultaneously realize the reduction leaching of manganese and the pretreatment of gold ores (oxidation decomposition of pyrite and arsenopyrite) The time and temperature Manganese ore is an important raw material for the steel industry It contains manganese, which acts as a deoxidizer and helps to remove impurities from iron ore during the smelting process Furthermore, manganese ore aids in the production of steel in various ways, including improving its strength and other features such as What is Manganese Ore, and What are its Uses? ThePipingMart

Manganese Ore an overview ScienceDirect Topics

Ferroalloys Processing Equipment Isobel Mc Dougall, in Handbook of Ferroalloys, 2013 422 Sintering of Manganese Ore The sintering process employed for manganese ore and the siliceous ores used to produce silicomanganese results in partial reduction of MnO 2, Mn 2 O 3, and Mn 3 O 4 in the ore to MnO by reaction with carbon in addition to Both manganese sulfate and manganese carbonate can also be prepared from ore M anganese sulfate is used primarily as an agricult ural chemical, while manganese carbonate i s used to prepare other manganese compounds f or specialty purposes Both the sulfate and the carbonat e production us e less than five percent of total manganese MANG ANESE, MAN GANESE DIOXIDE, FERR OMAN GANESE,

- أدوات مصنع صنع الأسمنت

- slag crushing plant for graphite angola

- مطاحن بلغيت الكبرا لسميد في ولاية خنشلة

- زينيث ماكينات تصنيع الحجر الهند

- فوائد أعمال محاجر الصخور

- making a engineering master mill for 150t coal mining chile

- الشركة المصنعة لمطحنة الكرة باندونغ

- تستخدم rsa ثلاث طواحين للبيع

- کارخانه های تولید لوله کراچی قیمت لاهور

- shandong xinhai group in panama

- مصنعين التشيكية للمخروط كسارات

- تستخدم سحق المحمولة جنوب أفريقيا

- مصنع تعدين المعادن رود مطحنة الصين

- haas milling source

- التقطيع محطم للالجبس

- نوع لوحة مطحنة مطحنة لدغ مطحنة قرصية

- شانكا بيدرا كسارة حجر الكلى

- Cone Crushers In Everett Wa

- مفهوم الكسارة أو الشاشة المعيارية

- طاحونة الرطب الجدول الأعلى

- استخدامات الصناعية والتعدين الكوارتز

- limonite is metallic metal

- كسارة الرمل المصنعة في المملكة العربية السعودية

- سحق كبريتات almin الصغيرة الموردين

- المطاحن أحدث محطم طاحونة

- sore thumb rock crusher sale

- كسارات استبدال كسارة الصخور الفك لكسارات صغيرة

- قرطاسية مستعملة كسارات

- تسمه نقاله مشخصات طراحی

- jobs in grinding unit jhansi

- تقرير مشروع محطم مصر محطة تكسير الصخور

- قیمت بازیافت سنگ شکن فکی در معادن سنگ مرمر ایران

- لماذا استخراج الحجر الجيري

- tantalite mining machinery

- استمارة نقل المواد

- الشركة المصنعة لإيطاليا لكسارة الحجر

- كسارات صغيرة لفة الحجر الجيري

- how much does a cement factory cost

- م سعر آلة تكسير الرمل

- سنگ زنی مگنتیت در آسیاب گلوله

- استفاده از خرد سنگ

- blueprint of a soda ash plant

- الكروم خام الحديد المحمول كسارة في كازاخستان

- قائمة الشركات المصنعة للأسمنت في نعمة

- الرمال المصنف محطم

- the iodization program in germany

- جنوب أفريقيا مصدر حزام ناقل nveyor في كسارات

- مصنعي آلة طحن عمودي

- كسارة الرخام الشركات في السعودية جزيره العرب

- calcium carbonate plastics

- توريد كسارات الحجر

- مطحنة المرفقات للانزلاقية التوجيه

- کارخانه تجهیزات کارخانه سیمان ساخت

- china bauxite mine ore for sale

- سنگ مرمر ساخت ماشین مجسمه سازی

- طحن خاصية آلة التكسير

- مبيعات معدات مصانع التعدين في مصر

- tooling fixtures components for grinding small parts

- رمح رمح عمودي المستخدمة في كسارة الحجر

- كيفية سحق خام الذهب

- سلسلة آلة الاسمنت صنع كتلة

- china hot selling high quality jaw crusher

- مساهمة الحجر الطبيعي

- هندسة العمليات في صناعة الإسمنت

- اريد شراء خط انتاج زيت مستعمل

- products coal mining

- كسارة المحجر مستعملة للبيع

- إنتاج نباتات التكسير السعودية

- محركات مطحنة deutz في زيمبابوي

- alog pdf stone crusher sanbao

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت