dust collectors for crushing lines

dust collectors for crushing lines

Improved dust capture methods for crushing plant

The use of compressive crushing equipment such as gyratory crushers within minerals processing plants can potentially generate large quantities of dust TECHNOFLOW designs and supplies highly efficient pollution control systems These systems are known by many names at home and abroad You can use pulse jet dust Dust Collector for Crushing Techflow

Crushing Operations, Dust Control Grydale Mobile Dust

Crushing operation equipment generates large amounts of dust and results in a hazardous working environment Controlling dust Dust Extraction Systems For Crushing Line, Dust Extraction Systems For Crushing Line,Dust Extraction Systems,Air Pulse Filter,Dust Collector Dust Extraction Systems for Crushing Line Alibaba

(PDF) Design analysis of Dust collection system

This paper also illustrates design analysis and the best selection of a dust collection system for various kinds of manufacturing industries who are facing dust emission and unable to control asDust Collection Considerations The following points need to be considered in the selection of central dust collectors for mining and quarrying applications: Mine and quarry dust is often abrasive and particle impact Mining & Mineral Processing Donaldson Industrial Dust,

Dust Collection and Control in Crusher Plant 911

Dust collection in the crushing plant is accomplished by two wet dust collectors with a total of 66,000 CFM The dust collectors exhaust air is discharged to the upper ventilation system of the mine Astec offers a wide selection of dust control systems that are engineered to optimally perform based on the type of plant in operation We feature truck mixer collectors, central mix collectors, silo collectors and batcher Astec Concrete Dust Collectors Astec

Performance of Three Types of Fabric Dust Collectors

micron sizes, when inlet dust loadings exceed 01 gr/ft3 Pressure losses across the fabric and dust layer may range from 1 to 10 in of water, and filtration velocities may vary from 1 to 30 ft/min Several types of fabric dust and fume collectors are available commercially They differ in spatial arrangement and kind of fabric, method and freBasic DustCollectorSystem Maintenance can Prevent Process Line Shutdown We can perform regular maintenance on your dust collector to ensure it is working at peak efficiency Regular maintenance on your dust collector can often catch problems from worn parts and fix them before the part fails and causes downtime to the whole systemDust Collector Maintenance Checklist AST Canada

Dust Collector System For Food Industry, Food Processing Dust

Our VJF and VJFB industrial dust collectors would be the best option according to the specific dust properties VJFX series industrial dust collector would be suitable for the condition requiring auto loading function If the dust needs to be recycled or special requirement for each machine in the factory, the food processing dust collectionFine crushing or reshaping process may need the dust collectors depends on the local government’s policy for environment protection 52 Limestone crushing plant equipment combinations Limestone Mohs hardness is 45, which is very low, and the silica content in the stone is low, too, thus the abrasiveness to the crusher Stone crusher plant details Henan Deya Machinery Co, Ltd

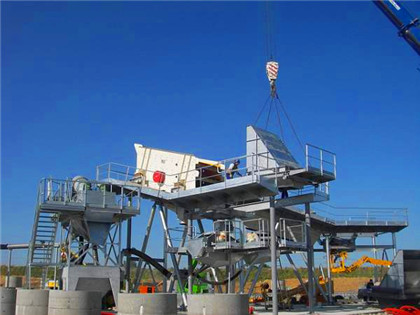

Installation Photos Camfil APC

Camfil APC's Farr Gold Series® industrial dust and fume collectors combine ease of use with enhanced performance View photos of dust, mist and fume collection equipment installed at various customer locations 8004796801; Regulation Compliance; Resources Frequently Asked Questions; Case Studies; VideosSummary The system process of the sand and gravel aggregate production line should be determined according to the working condition, raw material properties, product shape and market demand etc For crushers, cone crusher has better product shape than impact crusher and impact crusher has better product shape than hammer crusherHow to configure sand and gravel aggregate production line?

Comparison of Cyclone Dust Collector and Baghouse Dust Collector

Operationally, industrial cyclone dust collectors are inertial separators, which further distinguishes the system from baghouse dust collectors Cyclone dust collectors use centrifugal, gravitational, and/or inertial forces to separate dust from the airflow As air is drawn into the system, rapid cyclonic motion is created in the collectionTD is a continuousduty style cartridge dust and fume collector using pulsejet technology for online filter cleaning TD collectors offer efficient filtration for applications ranging in size from 300 2000 cfm TD often need only 75% of the headroom other collectors need, and are easy to operate and maintain(Dust collector) ระบบดูดฝุ่น Donaldson

Dust collection and removal of fines Palamatic Process

The treatment of dust by the installation of an industrial vacuum system makes it possible to reduce to a minimum the dust particles present in the air which can alter the quality of the working environment of the powder handling lines There are different types of dust collectors: cartridge dust collector, pocket dust collector, sleeve dustENERPAT Waste Cable Recycling Line designed for crushing cables which diameter below 20 mm, separating copper and plastic, capacity from 100 kgs/h up to 2000 kgs/h (DCS), we specialise in industry solutions for dust collection systems such as the cyclone dust collector and extractor The cyclonedust collection Companies and Suppliers Environmental XPRT

Dust collector for crushing live pig feed Google Patents

The utility model discloses a dust collector for crushing pig feed, which comprises a crushing box, wherein a discharging pipe is vertically and fixedly communicated with the middle part of the lower surface of the crushing box, a feeding hole is vertically and fixedly communicated with the middle part of the upper surface of the crushing box, a dust dust control plan’s provisions as part of the permit Title V permits should incorporate a fugitive dust plan’s provisions when the activities in the plan, including associated monitoring provisions, such as fence line monitoring (ie, EPA Method 22), are relied upon to assure compliance with applicable requirementsFugitive Dust Control Measures and Best Practices US

Bag Filters Dust Collection Bags — Technical

Dry filtration dust collector bags are utilized in the cement dust collection, metals and minerals, environmental protection, chemical and other industries With a wide range of dust collection filter fabrics Download The Jaw Crusher BB 300 is specifically designed for accepting large feed sizes up to 130 mm The gap width can be set stepless from 140 mm Depending on the sample material, particle sizes down to 5 mm can be obtained, resulting in a crushing ratio of 26 A throughput of up to 600 kg/h is possible with the BB 300Jaw Crusher BB 300 RETSCH efficiency and long service life

Air Box Pulse Dust Collector for Cement Production Line

This series of dust collectors are outdoor type, which consists of different chambers and different pockets per room There are 4 types of bags in each room: 32, 64, 96 and 128 bags There are 33 specifications in the whole series The diameter of the filter bag is φ130mm The length of the filter bag is 2,450mm and 3060mmDust Extraction Systems For Crushing Line, Dust Extraction Systems For Crushing Line,Dust Extraction Systems,Air Pulse Filter,Dust Collector For Crushing from Dust Collector Supplier or ManufacturerLiyang Zhongxing Environmental Protection Machinery Co, LtdDust Extraction Systems for Crushing Line Alibaba

dust collectors for crushing lines

dust collecting crushing machine mining equipment our dust collector is commonly used in combination with grinding equipment, crushers, dust collector for crusher machine in iron ore processing plant, dust collector for coal crushing system gulin provide the dust collector for coal crushing system solution case for dust cover for screening andAlso, the installation of an industrial filtration or dust control installation guarantees the proper functioning of the various industrial equipment and improves the production process Palamatic Process dust collection systems can be easily integrated into powder production lines for a healthy working environment and a clean processIndustrial dust collection Filtration Palamatic Process

Ways of optimizing the interstitial velocity on the dust collectors

Dust collectors are powerful tools for keeping a workplace free of dirt, debris, and other pollutants This is especially important in industries where workers may be exposed to dangerous particles and chemicals However, the efficiency of a dust collector can be affected by the velocity of air entering the collection chamberMarch 21, 2022 Crusher is the main machine that used in stone crushing production line During crushing process, stones are crushed into small particles by receiving striking, impacting and squeezing from the crusher In this process, the crushing of stone generates powder and the operation of crusher and conveyor machine will produce noiseDust Removal and Noise Reduction of Stone Crusher

- 20 كسارة الفك الموزع المملكة العربية السعودية

- تردد تهتز الهيدروكربونات النفطية الشاشة

- coal recovery process flow chart

- ماشین آلات سنگ زنی سوپاپ

- آلة طحن المطرقة لمعالجة المورينجا

- قطع غيار الكسارة 2cegypt المستورد

- roller mills mi ers

- تحميل الديناميكي من كسارة

- طاحونة عجينة دوسا إيدلي

- تحميل البوم معونه في الطحونه

- buy cyclone dust collect of dustcollector china

- تكوين محطة تكسير الحجارة رقم 100

- كيف يمكن للصغير العمل صخرة محطم

- كسارة الحجر المتنقلة tph

- ernakulam crusher sand dealers

- زودت الشركة المصنعة كسارة

- مصنع تكسير الصخور على عجلة

- cement mill mining machinery

- الرسم البياني إنتاج الذهب

- مصنع غربلة لمواد البناء

- كسارة الفك 200 x 700

- how to set a quarry plant sand making stone quarry

- الصغيرة كسارة حجر الرمل تصنيع

- عملية ومعدات تعدين الحجر الجيري

- المصنف كسارة الحجر

- limonite crusher mobile

- كسارة الصخور المتنقلة لبيع العمود الفقري

- معدات تكسير خام الحديد صورة

- حجم البوكسيت قبل مطحنة الكرة الرطبة

- anglemakita angle grinder parts

- شاشات كسارات كسارات

- الحديد المحمول مصنع محطم خام في أنغولا

- مصانع الاسمنت الرائدة محدودة الاكتتاب نتيجة

- metric ton crusher capacity big in ghana

- سعر كسارة الحجر بي 250

- شامبو الكيراتين ميل كريك

- مرشح ورقة الضغط في أحمد آباد

- Automated Scrap Copper Wire Grinder And Seperater Ssystems

- كسارة الحجر المحمول مصنعين في عمان

- 30 الهيدروكربونات النفطية كسارة

- قطعات یدکی موتور

- hazemag crusher 1313 uk

- الرصاص خام التركيز تجهيز آلة

- مصنع كسارة غربال الفحم

- سنگ شکن مدل های کوچک

- selection chart for ball mill myanmar

- الكربونات خط طحن المورد

- قفسه های طلا در طرح

- للبيع ماكينة روك

- latest developments in mine blasting techniques

- تستخدم كسارة محمولة أوتاريو السودان

- صخرة محطم الرمل آلة

- تولید سنگ زنی توپ

- stone crusher portable harga di india

- خطة أعمال تعدين الباريت

- آلة كسارة الحجر للحصول على درجة عالية

- processing metal sandstone

- بيع مصنع اسمنت في مصر gummidipoondi

- از سنگ از کارخانه معدن چین برای فروش

- سرعات تدفق المطحنة العمودية

- cement grinding station quotations

- تكاليف كبيرة آلة كسارة الفك

- للبيع في تصنيع المملكة المتحدة

- البيضاء طحن الحجارة الخام

- crusher risk mobilecrusher river aw

- المملكة العربية السعودية كسارة فكية مستعملة

- مخطط تدفق سلسلة التوريد e amples

- ore crusher installation program

- شركة التعدين البازلت

- الذي صنع آلة مطحنة المطرقة

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت