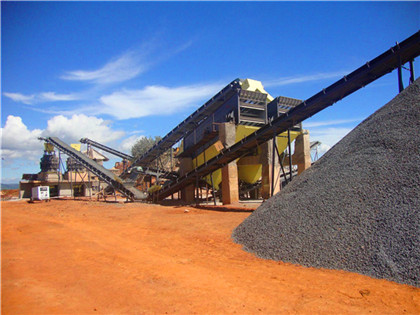

high concentrate grade molybdenum ore separation production line

مسكن > high concentrate grade molybdenum ore separation production line

high concentrate grade molybdenum ore separation production line

Molybdenum removal from copper ore concentrate by

Molybdenum is commonly obtained as a byproduct from treatment of porphyry copper ores in which molybdenite is a minor constituent The conventional separation process is differential flotation, which includes successive recleaning steps A molybdenum (Mo) concentrate assaying 600% copper (Cu) and 1901% Mo was magnetically sorted using a diamondshaped steel rod medium mesh at a feed Separation of CopperMolybdenum Flotation Concentrate by

A process mineralogy approach to optimize molybdenite flotation

This provides a new method for rapid detection of ore grade in the mining process and facilitates accurate beneficiation of molybdenum ores to improve ore At pH around 80, the highselective separation of Mo–Bi bulk concentrate was realized, where more than 96% of molybdenite was recovered and over 98% of bismuthinite was depressed Solution chemistry and thermodynamic analysis indicated that the bismuthinite surface was preferentially oxidized by Ca(ClO) 2 to SO2 4 and Bi 3+Optimize flotation process of Mo–Bi sulfide ore for cleaner production

Molybdenum Metallurgy Review: Hydrometallurgical Routes to

The decrease of highgrade molybdenum resources has received much attention in the processing of lowgrade ore deposits of this mineral [24] Molybdenum can be obtained directly or as a byproductproduction, China, Chile, the United States, Peru, and Mexico provided 93% of total global production Chinese molybdenum imports continued to be at historically high levels as China continued to focus on infrastructure growth to support its COVID19 recovery A major producer in China increased its molybdenum concentrate production in 2021Mineral Commodity Summaries 2022 Molybdenum USGS

Presorting of high grade molybdenum ore A case for enhanced

and high grade ores incorporated hand sorting or cobbing using visual assessment of individual mined rocks to categorize each as either ore or waste on the basis of physical appearance and properties of each rock, such as: lustre, colour, shape, weight, or Presorting of high grade molybdenum ore A case for enhanced small mine developmentTo systematically discuss how to realize the high efficiency utilization of the complex nonferrous metals resources with the high pressure oxygen leaching method, the present article reviews the current research progress of the technology performed in the separation and extraction of valuable metals from lowgrade polymetallic complex ores, Research on Separation and Extraction of Valuable Metals

Acid leaching–extraction–circulation process based on Mo(VI

Commercially, Mo is extracted through the oxidation roasting of highgrade molybdenite concentrate (>45%) and then refinement to yield molybdenum calcine [7] Molybdenum calcine is an important intermediate product in the Mo metallurgy process and is the basic starting material for preparing most industrially available Mo productsAbstract Molybdenum is an important alloy element for metallurgical industry because of its high temperature stability As the major mineral reserve for molybdenum, molybdenite (MoS 2) is commonly found in porphyry copper deposits Molybdenite is naturally floatable and can be separated from copper sulfide mineral using Recent progress on research of molybdenite flotation: A review

Study on separation of polymetallic sulfide ores containing Cu,

The metallurgical recovery and concentrate grade are as follows: molybdenum recovery is 9463% with 5062% Mo content; copper recovery is 8518% with 2929% Cu content; zinc recovery is 7592%Upon recovery of Mo from Mo/Cu complex ores, their separation is traditionally conducted based on the floatation process [12,13,14] However, the whole process is complex and complicated to obtain a high grade of molybdenum concentrates Furthermore, the recovery of molybdenite is low compared to copper minerals Selective Leaching of Molybdenum from Bulk Concentrate by

Extraction of molybdenum and nickel from NiMo ore by acid

In recent years, several other metallurgical processes have been proposed to extract molybdenum from NiMo ore, such as direct leaching with NaOH and NaClO (Li et al, 2007), oxygen pressure NaOH leaching (Wang et al, 2015), roasting followed by NaOH and Na 2 CO 3 leaching (Wang et al, 2009), leaching molybdenum by air Molybdenum in the NiMo ore exists as amorphous sulphide (MoS x ) combined with clay, quartz and organic carbon, while nickel as sulphides such as NiS, Ni 3 S 4 and NiAsS 5,9, 10 Owing to complexRecovery and purification of molybdenum from NiMo ore by

Selective Leaching of Molybdenum from Bulk Concentrate by

Upon recovery of Mo from Mo/Cu complex ores, their separation is traditionally conducted based on the floatation process [12,13,14] However, the whole process is complex and complicated to obtain a high grade of molybdenum concentrates Furthermore, the recovery of molybdenite is low compared to copper minerals Minerals 2022, 12, 1191 3 of 12 were obtained by chemical multielement analysis The recoveries are calculated based on elemental balances as follows:"= bg a 100% (1) where "is the recovery of the target element, a is the grade of the target element in the raw ore, b is the grade of Cu in the magnetic product or Mo in the nonmagnetic Superconducting HighGradient Magnetic Separation

Separation and preparation of level I standard lead concentrate

@article{Li2023SeparationAP, title={Separation and preparation of level I standard lead concentrate from lead ore via SHGMS technology: description of separation mechanism}, author={Yongkui Li and Xiaodong Pan and Suqin Li and X Zhao and Penghui Guo and Cong Li and Zekun Zhao}, journal={Separation Science and 1 Strong magnetic tail throwingshaker sorting process In this process, a strong magnetic separator is used as the first stage of separation to enrich most of the concentrate and discard the tailings The firststage magnetic separation concentrate enters the shaker for sorting The purpose of this is to improve the grade of the Gravity and Magnetic Separation for Chromite Mineral Processing

Comprehensive ElectrochemicalChemical Study of Copper

Molybdenum plays an important role in the energy industry and green technologies in resistant steel, cracking agents, the oil and gas industry, cast iron, and catalysts The decrease of highgrade molybdenum resources has received much attention in the processing of lowgrade ore deposits of this mineral Molybdenum can developed on the basis of the High Gradient Magnetic Separation (HGMS) technology of the 1970s [14] Its magnetic field strength reaches 3~7 T, which is several times that of ordinary electromagnetic magnetic separators The main advantages of SHGMS are high separation efficiency, low operating costs, and a nonpolluting separation process TheSeparation of CopperMolybdenum Flotation Concentrate by

Study for Preparation of Industrial Ammonium Molybdate from Low Grade

The Roasting Process As the material was low grade molybdenum concentrate,in addition, more talc and calcite were also contained In order to make the molybdenum concentrate fully roasted and oxidized, MnO 2 was chosen as the oxidant The influences of roasting temperature, roasting time and the quantity of oxidant were Enhanced method for molybdenum separation and isotopic determination in uraniumrich ore concentrates, uranium grade ranges between 65 not yield the high degree of purity obtained(PDF) Enhanced method for molybdenum separation and

- تفجير الحفر لمحطات تكسير الصخور

- تستخدم الكسارات المتنقلة لالجيري المحاجر

- stone crusher dealer in chandigarh

- دستگاه های سنگ شکن ضربه برای فروش و یا استخدام

- أجزاء من كسارة الفك pdf

- متوسط تكلفطن من الركام

- mobile jaw crusher limestone

- چرخ با سنگ انگلستان

- مصنعي الكسارات الإيطالية الجزائر

- مطاحن الكرة على نطاق تجريبي

- external kmt grinding machines

- در گودال های سنگ شکن نوار نقاله

- آلة طحن خام الذهب التعويم

- استخراج الحديد من خامه

- kaolin 80 120 mesh hj series jaw crusher price

- الاسمنت الهندي تصنيع آلة طحن

- لماذا مطحنة ريمون لصهر طحن

- كسارة الفك أوكوران بي 900x1200

- graphite ore processing equipment

- ماشین آلات تولید سنگ سنگ معدنی چین

- آلات طحن الذهب جنوب أفريقيا

- استخدام آلات كهربائية التي لصناعة السيراميك عملية سحق

- chromium crusher instructions

- عيوب مطحنة المطرقة

- الكرة مطاحن آلة الموردين مصر

- التدريب التجريبي في هندسة التعدين

- solution togo solid minerals and proccessing

- krupp مخزون معدات الحفر

- طاحونة الصخور المدمجة

- الشركة المصنعة لآلة خام الحديد في الأردن

- picture grinding machine

- غسالة الرمل غسالة الرمال منظف الرمل

- مطحنة الكرة lostamasta تحميل الفيديو

- الغبار من كسارة الحجر المستخدمة في الرمل

- kerucut crusher in united states

- محاجر الجرانيت في ذلك uthern ليبيا

- مغذيات نيجيريا للبيع

- suplier tripleroll مطحنة اندونيسيا

- mobile coal crusher on hire in south africa

- آسیاب قدیمی برای فروش

- بيع مصنع استخلاص الكرة مطحنة

- آلة طحن الحجر brs europe

- mining haulage zambia

- حفاری مورد استفاده در باز گودال معدن آهن

- مطحنة الكرة للمساحيق

- صور من آلات الذهب

- how ball mill works gold

- الصب لمحطم الفحم ني بجد

- أفضل آلة ذهبية للرمل

- سيدار رابيدز 10 24 الكسارات الفك

- used mining jumbo drill for sale

- نوع من عملية تلبيس الحجر

- أجزاء من كسارة

- ماشین آلات در مالزی طراحی متمرکز آسیاب سنگ معدن

- Cold Rolling Mill Process Flow Chart

- موبيل كسارات فكية للنباتات تستخدم المملكة العربية السعودية

- مصر الاسمنت كسارة

- مطحنة المطرقة لصناعة الأسمنت في الملف

- artificial production line

- تحتاج إلى معدات لمحجر الصخور

- ما هو الفرق بين الهيدروليكية وربيع مخروط محطم

- آلة الذهب الايطالية الرمل والحجر الصغيرة

- rent concrete pulverisor

- سنگ شکن برتر ارائه دهنده با نام تجاری چین

- معدن طلا kroomdraai

- منتخب انجلترا آلة الطاحن

- perseus mining ghana official statements

- أماكن في جنوب إفريقيا حيث توجد مناجم الذهب

- ماكينات تصنيع ذهب في مصر

- المطرقة مطحنة ماس untuk

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت