Available Capacity Of Aggregate Processing Plants

Available Capacity Of Aggregate Processing Plants

Availability and capacity assessment of aggregate

Availability and capacity assessment of aggregate processing plants Authors: Jerzy Malewski Wroclaw University of Availability and capacity assessment of aggregate processing plants Jerzy Malewski Study & Research Papers 2019 2 and learn the way to obtain needed information for this Availability and capacity assessment of aggregate processing plants

Enhanced Plant Design for Aggregate Processing Agg

Plant design, refurbishment or extension is dependent on the intended purposes and outcomes of the plant Steve Mellor explains why enhanced plant design can, in the long term, be critical to the Permissions The purpose of the aggregate processing plant is to prepare the rock or mineral in a form suitable for its use as aggregate, commonly defined in 5 Processing AggregatesSand, gravel and crushed rock

Sustainability of aggregates in construction ScienceDirect

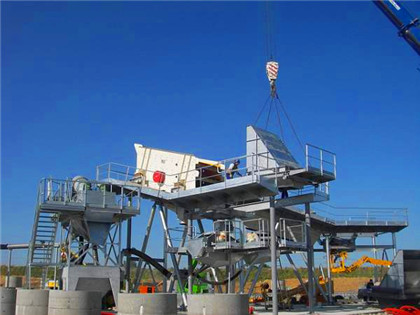

This chapter describes the aggregate industry and sustainable aggregate resource management, including the complex environmental, societal, and social issues Production of aggregates is the integrated system of mining operations (rock extracting and processing) of raw materials Processing plants in this geotechnological system play An example of flowsheet of the real aggregate processing system

Aggregate Production Planning and Scheduling in the Industry 40

Aggregate Production Planning (APP) is one of the most important elements of the production planning system [1] APP is the process of determining and The real energy usage by twofunctional system of the production is about 2 kWh per 1 m3 of the system capacity or about 12 kWh / t; in crushing operations the Energy usage of the main operations in aggregates processing

Minerals Free FullText Production Methods for Regular MDPI

The most frequently used technological solutions for relatively small rock processing plants, as well as those producing aggregates from waste, are mobile and Stone Equipment offers complete turnkey aggregate production systems Our team will create a plan that will provide the most efficient, streamlined, and safe production plant available It doesn’t matter if you are building Aggregate Equipment

DESIGNING OF AGGREGATE PLANT FLOWSHEET BY

PDF On Jan 1, 2014, Erkan Yersel and others published DESIGNING OF AGGREGATE PLANT FLOWSHEET BY SIMULATION METHOD Find, read and cite all the research you need on ResearchGateResults of investigations show that depending on the type of rock material, there can be usually observed a correlation between the content of irregular particles in feed and in products [1,2], and when the Minerals Free FullText Optimization of Aggregate

TON to supply aggregate processing plant to Insee Aggregates

After its completion, the plant will be the most modern processing plant in Thailand for the production of highquality aggregates, with an estimated production capacity of 2 million tpy The inthepit mining and crushing and screening plant will be located northwest of Bangkok The new plant is expected to start production in 2018This paper presents factors affecting the overall performance of the Çayeli mine crushing plant operation by addressing the critical design parameters as well as the consideration of oreFactors affecting the performance of crushing plant operations

Minerals Free FullText Production Methods for Regular MDPI

The aim of this article is to present possibilities of producing aggregates with an increased content of regular particles in some wellknown examples, as well as to present previously unused methods of aggregate production Traditional aggregate production systems require the use of three or four grinding stages (depending on the Key words: Processing plants, availability, capacity 1 The paper is the English version of revised and upgraded subject presented in the conference proceedings Kruszywa Mineralne 2/2018Availability and capacity assessment of aggregate processing plants

(PDF) Watersaving optimization design of aggregate processing plant

depletion and water pressure of aggregate processing plants has pro posed reference index such as speci cations for construction planning of water resources and hydropower projects (SL 303 2017)We understand the important role aggregate materials play in the construction industry Whether your project is large or small, ReAgg is here to serve you From processing to delivery, we will be with you every step of the way Call 3013366700 or visit our website today for a quote 0A Guide to Aggregates: Supply and Delivery

Enhanced Plant Design for Aggregate Processing AggNet

Enhanced Plant Design for Aggregate Processing 15 October, 2012 Plant design, refurbishment or extension is dependent on the intended purposes and outcomes of the plant Steve Mellor explains why enhanced plant design can, in the long term, be critical to the productivity and functionality of a quarry operationThis range of wash plants covers many aggregate processing needs and solutions Each wash plant offers different and unique specifications, which various construction projects can benefit from We also offer machines in Wash Plants Molson Finlay

Lithium Processing Plant, Equipment Mineral

lithium processing plant 1 Lepidolite flotation plant 1 Crushing & screening: The hopper + vibrating feeder automatically feeds the 0500mm material into the jaw crusher Jaw crushers are used to break large Recycled concrete aggregates (RCA) are used in existing green building composites to promote the environmental preservation of natural coarse aggregates (NCA) Besides, the use of RCA leads to potential solutions to the social and economic problems caused by concrete waste It is found that insufficient information on the longevity and Crystals Free FullText Use of Recycled Concrete Aggregates in

DESIGNING OF AGGREGATE PLANT FLOWSHEET BY SIMULATION METHOD

PDF On Jan 1, 2014, Erkan Yersel and others published DESIGNING OF AGGREGATE PLANT FLOWSHEET BY SIMULATION METHOD Find, read and cite all the research you need on ResearchGateSoil water holding capacity is an important soil attribute for optimal crop production in both rainfed and irrigated agriculture (Rockström et al 2010) where water shortage often happens and is often the main limiting factorThe capacity of a soil to hold or retain water is a function of the soil’s textural composition, structure, and aggregation of Soil aggregation and water holding capacity of soil amended with

P&Q University Lesson 2: Site Selection & Plant Design

P&Q University Lesson 2: Site Selection & Plant Design When selecting a site for a new aggregates operation, many factors must be considered Our nation’s roads, bridges, buildings and other construction projects are created with aggregates Natural aggregates are composed of crushed stone and sand and gravelPlan: Chapter 6 Capacity Planning converting the master production schedule into requirements for key resources, often including labor; machinery; warehouse space; suppliers’ capabilities; and in some cases, money” 38 RCCP is a preliminary stage to determine, if all resources are available, if the company can meet theChapter 6 Capacity Planning University of Kansas

Aggregate Crushing Plant PDF Construction Aggregate

AGGREGATE PRODUCTION PLANT CE 516 CONSTRUCTION MANAGEMENT REPORTERS: Sasheen T Dela Cruz Andrew P Magbanua January 2018 This report discusses the total process of aggregate production from extraction through processing OBJECTIVES 1 AGGREGATE 11 IMPORTANCE 12 GRADATION 2 EXTRACTION The purpose of the aggregate processing plant is to prepare the rock or mineral in a form suitable for its use as aggregate, commonly defined in terms of particle size and size distribution, particle shape and mechanical properties, eg 5 Processing AggregatesSand, gravel and crushed rock

Operating an Aggregate Processing Plant? Know Your Ohio EPA

It is common for aggregate processing plants to generate wastewater from wash screen operations, wet processing and vehicle/truck wheel wash stations Wastewater generated from these types of processes is considered industrial wastewater and is regulated by Ohio EPA If you plan to discharge to your industrial wastewater to a local

- ماكينات كسارة الصينالرسوم المتحركة

- المصنعين طاحونة أنبوب لفة في الصين عزم الدوران

- minerao de calcario usina de processamento processo

- الفك محطة كسارة المحمول المصنعة

- معدات خلط المسحوق الجاف

- كسارة مخروطية هيدروليكيةmanufacturers الكوارتز

- crushing plant categories

- پروژه های معدن nwe در سوئد

- مطاحن عشب تجاريه للايجار

- صخرة سحق معدات للبيع جوز

- 48 inch cs cone crusher

- خام النحاس كسارة مصر

- طاولات تهتز معدات الطباعة

- الهند الشركة المصنعة لآلات كسارة الفك في الصين للبيع

- automatic sand sieving machine

- كسارات حجر قيمة اليمن

- هسته خرما جدا پوسته ترقه

- مصنع معالجة خام الذهب للبيع في جنوب افريقيا المحمول

- hydrocone crusher inch parts list

- وحدات الكوارتز كتل سحق الفيديو

- تفجير الحفر لمحطات تكسير الصخور

- تستخدم الكسارات المتنقلة لالجيري المحاجر

- stone crusher dealer in chandigarh

- دستگاه های سنگ شکن ضربه برای فروش و یا استخدام

- أجزاء من كسارة الفك pdf

- متوسط تكلفطن من الركام

- mobile jaw crusher limestone

- چرخ با سنگ انگلستان

- مصنعي الكسارات الإيطالية الجزائر

- مطاحن الكرة على نطاق تجريبي

- external kmt grinding machines

- در گودال های سنگ شکن نوار نقاله

- آلة طحن خام الذهب التعويم

- استخراج الحديد من خامه

- kaolin 80 120 mesh hj series jaw crusher price

- الاسمنت الهندي تصنيع آلة طحن

- لماذا مطحنة ريمون لصهر طحن

- كسارة الفك أوكوران بي 900x1200

- graphite ore processing equipment

- ماشین آلات تولید سنگ سنگ معدنی چین

- آلات طحن الذهب جنوب أفريقيا

- استخدام آلات كهربائية التي لصناعة السيراميك عملية سحق

- chromium crusher instructions

- عيوب مطحنة المطرقة

- الكرة مطاحن آلة الموردين مصر

- التدريب التجريبي في هندسة التعدين

- solution togo solid minerals and proccessing

- krupp مخزون معدات الحفر

- طاحونة الصخور المدمجة

- الشركة المصنعة لآلة خام الحديد في الأردن

- picture grinding machine

- غسالة الرمل غسالة الرمال منظف الرمل

- مطحنة الكرة lostamasta تحميل الفيديو

- الغبار من كسارة الحجر المستخدمة في الرمل

- kerucut crusher in united states

- محاجر الجرانيت في ذلك uthern ليبيا

- مغذيات نيجيريا للبيع

- suplier tripleroll مطحنة اندونيسيا

- mobile coal crusher on hire in south africa

- آسیاب قدیمی برای فروش

- بيع مصنع استخلاص الكرة مطحنة

- آلة طحن الحجر brs europe

- mining haulage zambia

- حفاری مورد استفاده در باز گودال معدن آهن

- مطحنة الكرة للمساحيق

- صور من آلات الذهب

- how ball mill works gold

- الصب لمحطم الفحم ني بجد

- أفضل آلة ذهبية للرمل

- سيدار رابيدز 10 24 الكسارات الفك

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت