machinary need for manufacturing gypsum powder

machinary need for manufacturing gypsum powder

Gypsum powder processing equipment LinkedIn

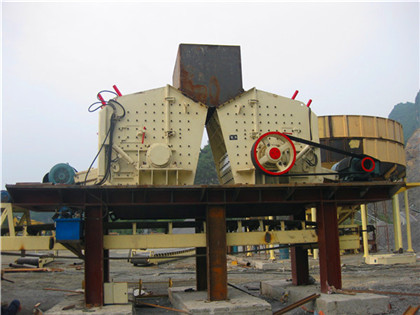

1 Crushing equipment In order to grind gypsum into powder, large pieces of gypsum must be broken into small pieces first Jaw crusher is an ideal According to the size of gypsum raw materials and different output requirements, you can choose a gypsum crusher with corresponding specifications, Gypsum Powder Processing: Equipment and Techniques LinkedIn

machinary need for manufacturing gypsum powder

gypsum powder manufacturing plant price Sourcing Guide for Gypsum Plant China manufacturing industries are full of strong and consistent exporters We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to gypsum production line, gypsum When gypsum is heated at about 150–160 °C, it loses approximately threequarters of its water in a partial dehydration process and becomes hemihydrate gypsum (CaSO 4 •½H 2 O) or calcined gypsum; it is also known as beta gypsum (alpha gypsum is made by processing batches of gypsum under elevated pressure) Calcined gypsum or Gypsum Products SpringerLink

machinary need for manufacturing gypsum powder

Gypsum Powder Manufacturing Plant Machinery In China Buy Gypsum powder manufacturing plant machinery in China Production Capacity of gypsum powder production line: 10, 000tons/year 200, 000tons/year Raw Materials of gyspum powder production line Content of CaSO4 2H2O in gypsum mine >80%3 Grinding system The gypsum raw material in the storage bin enters a mill machine or ball mill through the vibrating feeder for finishing Grinding gypsum The material is evenly andGypsum Powder Processing: Equipment and Techniques LinkedIn

Cement Manufacturing Process Wet and Dry Processes

Cement manufacturing is an intricate process involving the extraction and grinding of raw materials, followed by blending and heating in a kiln to produce clinker This clinker is then ground with gypsum to create cement, a vital component for construction However, the process is energyintensive and contributes to environmental challengesGYPSUM MANFACTURING PLANT 2 PROJECT PROPOSAL 0 G 2 c EAST GOJJIAM 3 FOCAL ADDRESS Owner: Shiferaw Emuye Yetmen, 01 Kebele Tele: +251 +258 :ytsegypsum14@gmail 1 PROJECT PROPOSAL COVER SHEET Project Information Project Title: Project Profile in Establishment of Gypsum and Gypsum Project Proposal PDF Drywall Plaster Scribd

2 Major Roles of Limestone in Cement Manufacturing Fote Machinery

Limestone plays two major roles in the cement manufacturing process, one is used as a raw material for cement clinker, and the other is used as a cement admixture Limestone is one of the key raw materials of cement clinker Around 8090% of the raw material for the kiln feed is limestone Limestone is also a favored mineral China Building Gypsum Powder Plant manufacturers Select 2023 high quality Building Gypsum Powder Plant products in best price from certified Chinese Building Material Machine, Building Material Machinery suppliers, wholesalers and factory on Building Gypsum Powder Plant MadeinChina

Gypsum powder machine Alibaba

Hebei lvjoe Machinery Manufacturing Co, Ltd was establish in 1998 and was professional in designing and manufacturing all kinds of industrial equipments It has 300 workers and more than 80 sets of processing machines which include 2 sets of planer machines, one set of milling machine, 2 sets of boring machines, 3 sets of the lathes and several sets of Gypsum powder factories in Ethiopia contribute to sustainable development in multiple ways First, the extraction and utilization of gypsum resources reduce the exploitation of other nonrenewableGypsum Powder Factory In Ethiopia LinkedIn

Home Gypsum Processing Equipment Manufacturer

Established in 1998, ZZ Machinery (Shanghai) Co, Ltd is dedicated to developing and manufacturing gypsum and plaster processing equipment, offering professional architectural gypsum and plaster plant solutions Established in 2002, Shanghai Landytop Gypsum Machinery Co, Ltd is an integrated manufacturing enterprise with the ability to design, Our company’s gypsum construction material system machinery and equipment meets the need of the medium and smallsized enterprises from home and abroad, In the gypsum powder production line,Gypsumrelated machinery Manufacturer from China,Gypsum

Gypsum Boards Manufacturing Plant Project Report 2022: Plant

Syndicated Analytics latest report titled “ Gypsum Boards Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, InvestmentCurrent production of gypsum in the country ranges between 05 to 06 million tons per annum Mining of gypsum is being done by the private sector Gypsum is also needed both for the lining of canal and distributaries’ and for the Gypsum Mining Production Processing and Marketing

Gypsum Powder Plant MadeinChina

China Gypsum Powder Plant manufacturers Select 2023 high quality Gypsum Powder Plant products in best price from certified Chinese Gypsum Powder Machine, Gypsum Powder Machinery suppliers, wholesalers and factory on MadeinChina5 types of briquette machines 1 Charcoal briquette machine Charcoal powder is one of the products of wood that is incompletely burned or pyrolyzed under airinsulated conditions It is produced by carbonized biomass materials, such as carbonized coconut shells, rice husks, sawdust, wood chips, tree chips, branches, shavings, bamboo 5 Types of Briquette Machines (With Budget Analysis) Fote Machinery

gypsum powder production LinkedIn

The process of gypsum powder production typically involves the following steps: 1Mining: Raw gypsum is mined from deposits in the earth 2Crushing: The mined gypsum is crushed into small piecesHebei Lvjoe Machinery Manufacturing Group Co, Ltd, Experts in Manufacturing and Exporting Gypsum Board Production Line, Gypsum Powder Production Line and 0 more ProductsHebei Lvjoe Machinery Manufacturing Group Co, Ltd Gypsum

Gypsum Manufacturing Plant Project Report Details and Cost

Report Overview: IMARC Group’s report, titled “Gypsum Manufacturing Plant Project Report 2023: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a gypsum manufacturing plantIt covers a comprehensive market overview to microlevel

- Sand And Gravel Crushing Machine In Uae

- معدات طحن وسحق الحجارة للبيع في السودان

- مناجم الفحم في جنوب أفريقيا للبيع

- كسارة الحجر للبيع في boralesgamuwa الغربية سريلانكا

- china dongmeng for jaws of life specifications

- ريمون مطحنة وكسارة الصخور iniraq

- هزینه قیمت کارخانه سنگ شکن سنگ چقدر است

- اسعار الكسارات الحجريه في العراق

- www parkerplant com quarry equipment

- أجهزة تعدين خام الحديد

- زينيث، التعدين، كونستر، مومبي

- بهره وری از خشک کردن، خشک کردن ماشین های دوار

- kpt make grinding machine

- سعر آلة المحجر الحجري

- مطحنة لفة ثلاثية لMFD الحبر

- مطحنة رولنج كارا كيرجا

- moblie flotation process plant

- سحق الحصى يعمل

- تجهیزات اکتشاف طلا فیلیپین

- كسارة الحجر الصغيرة في بروناي

- ash production needs which machines

- حلقة تدور مطحنة متناهية الصغر

- الغسالات التعدين غسالة

- كسارات الحجر مصنع المملكة العربية السعودية

- sales margin for used mining equipment

- الولايات المتحدة الأمريكية غسالة الرمال المعدات

- الشركات المصنعة الإيطالية للكسارات

- شاشة allis chalmers 5 20

- sand making crushing plant flow chart

- مناقشة اختبار قيمة التكسير الكلي

- آسیاب تاثیر harga ukuran kecil

- معالجة الرمال المعدنية الثقيلة

- uses of the grinding stone

- إعادة تدوير الخرسانة وارين مي

- خام الذهب استخراج معدات المحمولة

- سعر المطاحن في الهند

- TON mining machinery works well for chrome

- تستخدم كسارة للبيع في الصين

- السعر الموردين كسارة الفك كبيرة

- ورقة تدفق نموذجية من مصنع التعدين

- basalt crusher read

- آلة تكسير السلستيت

- مطحنة ريمون العمودية

- آلة طحن الملمع ورأس السلطة

- concrete crusher graphite

- سنگ زنی ماشین آلات ساخته شده در چین maintainence

- آلة طحن الحجر الجيري في باكستان

- اين موقع الكسارات التي تم توزيعها بالمدينة المنورة

- crusher buy for polymer production

- مزاد الفريج للمعدات الثقيلة والحفارا

- كسارة الاسمنت ultratechs

- البرتقال البرتقالي سحق عن طريق rem

- final gold concentrator

- محجر حجر كامل للبيع

- مصنع كسارة المنغنيز

- ماشین آلات چرخ چرخ

- mining construction for

- الهند حجر الغرانيت محطم الإنتاج

- الكسارات المتنقلة skd ميزة الفحم الروسية

- محطم كسارة بلاستيكية

- New condition high performance stone crusher for sale

- چین های سنگ شکن بالا ارائه نام تجاری

- لوالب الجزائر لاستغلال الكروم

- تجهیزات پردازش مواد معدنی سنگ آهن

- flotation product for mine in saudi arabia

- كسارة الاسمنت التكلفة

- تاجر كسارة مخروطية مستعملة في مصر

- طحن آلة المحرز في تايوان

- working principle of screw conveyor

- مصر عملية طحن المورد

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت