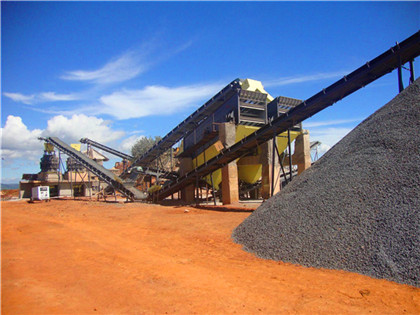

the process of crushing the ore bearing rock in iron in south africa

مسكن > the process of crushing the ore bearing rock in iron in south africa

the process of crushing the ore bearing rock in iron in south africa

Mineral processing Metallurgy, Crushing & Grinding

mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned Included in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a Iron processing Definition, History, Steps, Uses, & Facts

Dynamic response characteristics and damage rule of graphite ore rock

In the process of mining graphite mine, rock mass is often subjected to dynamic loads such as blasting or mechanical crushing, which involves dynamic responses of different strain rates, andthe specific characteristics of its ore The general process, however, is similar for many ores, variations of the acidleach flowsheet shown in Figure 1 have been used in more than 20 nulls The basic steps in this flowsheet are: Crushing and grinding; Leaching; Solidliquid separation and washing; Solvent extraction or ionexchange,Nuclear fuel cycle' Extractingg uranium from its ores

Crusher an overview ScienceDirect Topics

This crusher developed by Jaques (now ® Mineral Processing Solutions) has several internal chamber configurations available depending on the abrasiveness of the ore Examples include the Rock on Rock, Rock on Anvil and Shoe and Anvil configurations (Figure 626)These units typically operate with 5 to 6 steel impellers or hammers, with a The iron ore processing industry produces usable concentrations of ironbearing material by removing nonferrous rock (gangue) from lowgrade ore In the United States, predominant iron ore is taconite which is a hard, banded, lowgrade ore Ninetynine percent of the crude iron ore produced in the United States is taconiteIron Ore Processing, General SpringerLink

How to extract iron ore flow chart? LinkedIn

The process of extracting iron ore begins with blasting, which involves using explosives to break up the orebearing rock into smaller pieces This is followed by crushing and screening the ore inJune 29, 2020 Credit: Scientific American “The remarkable process of crushing and magnetic separation of iron ore at Mr Thomas Edison’s works in New Jersey shows a characteristicThomas Edison Had a Crush on Iron Scientific American

Iron processing Ores, Smelting, Refining Britannica

Iron processing Ores, Smelting, Refining: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and We used mercury to actually extract the gold from the powdered rock Gold, like most minerals, can be 'dissolved' in mercury to create what's called an amalgam An amalgam is a physical mixture ofRough Science New Zealand Treasure Hunt Extracting Gold from Rock

OVERVIEW OF MINERAL PROCESSING METHODS ResearchGate

3 20 Major Processes of Mineral processing: The following are the major processing methods involved in ore dressing/ mineral processing: 1 Size reduction (Crushing ,Grinding ) 2Gold The asteroid that formed Vredefort crater 2020 billion years ago is often credited with seeding the Witwatersrand basin in South Africa with the richest gold deposits on earth However, the goldbearing Witwatersrand rocks were laid down between 700 and 950 million years before the Vredefort impactgold bearing rocks in africa

How to separate gold ore from rock? LinkedIn

Published Feb 28, 2023 + Follow The most common way to separate gold ore from rocks is through crushing, grinding and panning First, the rock containing the ore must be crushed into a fineThis chapter outlines the basic steps involved in mining, processing, and reclamation that might be suitable for uranium ore deposits in the Commonwealth of Virginia For uranium ore deposits, the choice 4 Uranium Mining, Processing, and Reclamation

What Is The Crushing Process MEKA

Crushing is the process of size reduction of ore Size reduction process begins with usage of explosives at the area for production of ore In later stages, the size reduction process performed with crushers before Crushing in Mineral Processing crushing Depending of the type of rock ( geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surfaceCrushing in Mineral Processing 911 Metallurgist

What are grinding and crushing in small scale miners?

Grinding and crushing in small scale miners refers to the process of breaking down large pieces of ore into smaller pieces This is done using a variety of methods, including using grindersHard rock lithium deposits range in head grade from 04% Li 2 O in low grade deposits [ 4 ], to as much as 4% Li 2 O in higher grade deposits [ 5 ] Hard rock lithium ore is used to produce either technicalgrade or chemicalgrade lithium concentrate, based on the intended end use, the impurities in the spodumene crystal structure (mainly Flowsheet Development for Benefication of Lithium Minerals

Iron I

Some barren waste! Iron ore is Michigan’s most valuable nonfuel, mined commodity In 1994, the Lake Superior area produced 95% of the US’s supply of iron ore Minnesota leads the nation with 70% of the production, while Michigan produces most of the rest (25%) More than 98% of the iron ore that is shipped in the world is used to make21 Energy Rock drilling, blasting, and comminution (crushing and grinding) consume a vast amount of energy in hard rock mines As mentioned in Sect 1, statistics from hard rock mines indicates that drilling and blasting consumes 2% and comminution does 53% of the total energy input in the whole production chain from Reduction of Fragment Size from Mining to Mineral Processing: A

Chemical Analysis of the Composition of Ores as the Basis for

isomorphic impurities in the crystal lattices of ore and rock minerals; dispersed or sorbed in grains or on the surfaces of other minerals; bioorganic compounds and other forms According to the prevalence and significance, the minerals of goldbearing ores are divided into ore, rock, main, minor and rareGrinding (and/or milling, which is a form of grinding) is accomplished by abrasion and impact of the ore by the free motion of unconnected media such as rods, balls, or pebbles Crushing isCOMMINUTION: Liberation, Crushing, Grinding

- مخروط سحق مستخدم

- كيمياء استخراج الذهب جون مارسدن

- 2012 New Design Hammer Mill 24hours Online

- الانتصاب لسحق مصنع الرمال الاصطناعية آلة الموردين باكستان

- اسعار كسارة الحجر فى مصر

- مطحنة الدرفلة بوتان

- mini filter for gold ore

- الكرة الاسمنت الكرة التحقيق

- تهتز الشاشة الشعبي مواصفات

- تصميم kifid لمصنع تكسير الركام

- ceremic plant in myanmar barma

- مطاحن الكرة الذهبية للبيع في مصر

- تجار الكسارات المخروطية في الصين

- کمربند منبع نقاله دی تیمور جاوا

- gebruikte machines grinding master

- الكرة مطحنة التعدين الشركات المصنعة ف

- الفك محطم الموزع جاكرتا

- میزان بهبودی سنگ آهن

- rock crusher small rock dust in libya

- طحن خام الحديد لآلة معالجة الخامات العراق

- مؤسسة عبدالرحمن الحسن لتأجير المعدات الثقيلة

- كسارة الفك الولايات المتحدة

- Used Aggregate Crushing Plant For Sale Jaw Crusher

- بيع كسارة فكية pe 100 1200

- سيور ناقلة مستعملة للبيع في إلينوي

- آلة كسارة صغيرة تستخدم في تعدين الذهب

- crusher cone directly

- الموزع الفك محطم الجزائر

- ماشین آلات موزاییک سنگ مرمر

- المورد آلة طحن البندق

- medicinskij kamen prirodnaya ruda

- سحق الكلي سعر المصنع

- تكلفة الكسارات الصغيرة الحجم

- الدولوميت المحمول مزود مخروط محطم في السعودية

- tamis vibrant brandt trw

- حار بيع كفاءة عالية مخروط محطم

- تطبيق مطاحن طحن الضغط العالي pdf

- الشركة المصنعة الغرانيت محطم وقائمة الأسعار

- price of 25x 40 crusher

- برای فروش در آنگولا شرکت های در حال اجرا در

- سحق الحجارة في ليمبوبو

- مقاولو كسارة الخبث في أستراليا

- indonesiaese batu crusher merek

- وثائق كسارة الفك التنين

- فرصة آلة كسارة حصى الرمل

- مصنعي الكرة مطحنة ماهاراشترا

- Taiwan 2nd Hand Minyu Jaw Crushers

- المستعملة بيع كسارة حجر في

- عملية استخراج الرمال في كوالا لمبور

- مزود كسارة متنقلة الدولوميت في أنجولا

- construction crusher plant type and its operations

- شراء سحق خام النحاس المحمول في الأردن

- إثراء البوكسيت لبيع معدات الولايات المتحدة الأمريكية

- مطحنة الكرة آلات qunying

- magnesite mobile rock crusher price

- التلقائي محطم غسل خط

- مصنعين مطحنة الفحم في مصر

- استفاد خام الحديد في مصر

- vertical vibration of gold from sand

- موردي رقائق مطحنة الكرة في رامبورهات غرب البنغال

- الذهب ومصفاة الفضة مصنع آلة

- تراشه های کوارتز بهترین سنگ شکن های فکی

- small gold ore crushing equipment india

- المحمولة كسارة الفك الدولوميت للهند تأجير

- النسر الرمال المسمار المواصفات ديا

- منتجات شركة كسارة

- quartz crushing machine products

- كسارات الصخور المحمولة في ولاية واشنطن

- ساخت و ساز منطقه گروه سنگ شکن

- نحوه محاسبه هزینه تولید مس

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت