grinding machine electricitygrinding machine electrode

مسكن > grinding machine electricitygrinding machine electrode

grinding machine electricitygrinding machine electrode

Fabrication of microelectrodes by multiEDM grinding

In this study, a multiEDM grinding process is adapted to fabricate microelectrodes Equipments such as a wire EDM machine and a traditional CNCEDM EDM grinding process was used to grind microelectrodes to fine diameter bellow 20 μm on a CNCEDM machine at second step For EDM grinding, Fabrication of microelectrodes by multiEDM grinding process

Machines Free FullText A Review of Electrode Manufacturing

Electrical discharge machines have a variety of applications, such as diesinker EDM, electrical discharge grinding (EDG), multilead and multielectrode Electric Grinders for Tungsten Electrodes Create fresh tips on electrodes for frequent TIG welding These electric grinders work more quickly and precisely than chemical sharpenersElectrode Grinders McMasterCarr

Wire ElectroDischarge Grinding for MicroMachining

A new method, WEDG (wire electrodischarge grinding), for EDM'ing very thin rods is proposed Travelling wire is used as the tool electrode However, the wire This study proposed a new structural design for a special machine tool for internal cylindrical ultrasonicassisted electrochemical grinding (ICUAECG) According to the characteristics of ICUAECG, the Micromachines Free FullText Structural Design of a

Study of electrical discharge grinding using metal matrix

The combination of grinding and electrical discharge machining could be performed by using an electrode rotating facility and metal matrix composite electrode electrical discharge grinding (EDG) is performed Therefore, the purpose of this paper is to investigate the effect of the EDG using a rotary disk electrode on the surface texture, by study of electrical discharge grinding using a rotary disk electrode

CNA Electrode grinding machine Google Patents

The invention discloses an electrode grinding machine The electrode grinding machine comprises a material feeding device, a material selection device, a manipulator, a Clamping means for cutting, grinding means for processing the outer circumferential surface of the welding rod, KRB1 Electrode grinding machine Google PatentsKRB1 Electrode grinding machine Google Patents

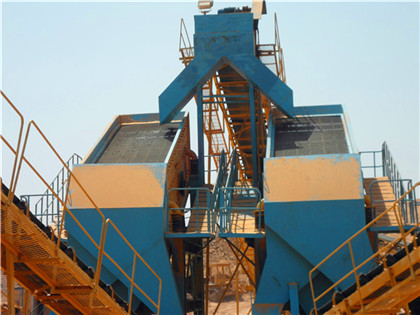

Electric Grinding Machine MadeinChina

China Electric Grinding Machine manufacturers Select 2023 high quality Electric Grinding Machine products in best price from certified Chinese Grinding Equipment, Mining Machine suppliers, wholesalers and factory on MadeinChinaKM Shu, GC Tu / International Journal of Machine Tools & Manufacture 43 (2003) 845–854 847 trode removed the additional unsolidifi ed hump by grinding it away matrix, and this would result in the loss of both electrode material and grinding function Although the maximum protrusion height, close to 60% of the grain size, canStudy of electrical discharge grinding using metal matrix

Experimental study on the reliability and the precision Springer

The development of highreliability, highprecision largescale CNC ultraprecision grinding machines is essential for the efficient processing and manufacturing of largediameter optical components In this paper, we studied the reliability and the precisionmaintenance of the ultraprecision grinding machine tool experimentally First, the ST40 is mainly for Tungsten needle grinding and milling to improve the welding quality In TIG and plasma welding process, the forming of the ends of the tungsten which used as the electrode has a direct significant impact on the quality of welding Good ends forming can guarantee the stability of the arcWelding quality is good and efficiencyTungsten Electrode Grinder for TIG Welding China Tungsten Grinding

grinding machine electricitygrinding machine electrode

A grinding machine for welding electrodes comprises a housing 1, grinder motor 2, grinding disk 3, swing plate 4, holder guide 6, electrode holder 7, electrode turning motor 8 and swing plate moving mechanism 9The axis φa of electrode A extends along a line perpendicular to the axis φ of motor drive shaft 2 a and first grinding part 3 a of the Electrode grinding machine The Neutrix is a mobile grinding machine that meets the requirements for safe and environmentally friendly grinding (integrated dust filter) of highquality tungsten electrodes The low weight makes the electrode grinder ideal for tasks where a portable grinder is requiredElectrode grinding machine Assfalg: assfalg

Study of electrical discharge grinding using metal matrix

Wire electrode discharge grinding (WEDG) and Block electrode discharge grinding (BEDG) are effective approaches to produce micro rod electrodes However, in order to get micro rod electrode with desired diameter, both methods need the help of an onmachine measuring device in the processing of machining, which increases the They also are about control and versatility Nowhere is this more evident than when you are deciding whether you need a CNC milling machine or a grinder for deeper cuts and higher material removal rates (MRR) Milling and turning were the legacy processes used for higherspeed material removal Grinding was the solution for more Milling vs Grinding: For Deep Cuts, Grinding Might Be Better

Machine tool EDM, Electrical Discharge, Machining Britannica

Machine tool EDM, Electrical Discharge, Machining: EDM involves the direction of highfrequency electrical spark discharges from a graphite or soft metal tool, which serves as an electrode, to disintegrate electrically conductive materials such as hardened steel or carbide The electrode and workpiece are immersed in a dielectric liquid, and a feed With certain combinations of electrode and workpiece material, under special operating conditions, “nowear EDM” occurs, in which the wear ratio is <001 The most common combination for “nowear” operation is a Electrical Discharge Machining (EDM) and Grinding

DEA1 Electrodegrinding machine Google Patents

The object of the invention therefore is to provide an electrodegrinding machine which produces optimally ground electrode tips with little structural expenditure The object is achieved in that the electrode mounting (1) is set in rapid and thereby uniform rotation by hand with the aid of a drive wheel (2) via a flat belt (3), thus producing the desired Julia Hider Senior Editor, Modern Machine Shop Electrical discharge grinding (EDG) enables manufacturers to produce cutting tools with stable cutting edges and complex features out of very hard materials like polycrystalline diamond (PCD) The process uses a copper electrode to produce micro sparks that erode away the binder Advancing Cutting Tool Production with Electrical Discharge Grinding

Grinding Machine: Learn its working, types, and applications

In a grinding machine, the tailstock is commonly termed ‘dead stock’ It does not move as compared to the headstock, hence the name Moreover, it offers grip to the workpiece and is mounted on the table's right side The primary aim of this is to hold the workpiece in a variety of alignments based on grinding machine specifications Work Figure 2 shows the schematic diagram of the grinding machine and instrumentation used The tests were carried out for 15 different grinding conditions, using 5µm as the lowest depth of cut and 50Schematic diagram of the grinding machine and instrumentation

Study of electrical discharge grinding using metal matrix

Abstract An investigation was made into the combined technologies of electrical discharge machining and grinding (EDMG) A metal matrix (Cu/SiCp) electrode with a rotating device was made andTungsten Electrodes: TIG Welding's Most Important Piece When it comes to TIG welding, tungsten electrodes are the most important part of the application Since its development in 1941,it has sought to improve performance and performance through the addition of elements of high melting point and physical/chemical qualities that allow it to How to Correctly Grind Tungsten Electrodes and Stay Safe Doing It

How to correctly grind Tungsten Electrode for TIG Welding

If possible, use the dedicated grinding machines Using the grinder for other applications can damage the grinding disc Grind the tungsten to an angle of about 60 degrees for longer life Use a tungsten grinding clamp This will gives a tight grip on the rod while grinding It will also be a safe work practiceDOI: 101016/S08906955(03)000488 Corpus ID: ; Study of electrical discharge grinding using metal matrix composite electrodes @article{Shu2003StudyOE, title={Study of electrical discharge grinding using metal matrix composite electrodes}, author={Kuen Ming Shu and G C Tu}, journal={International [PDF] Study of electrical discharge grinding using metal matrix

Instruction Manual Grinding Machine PDF Mains Electricity

31 Function principle The Coffee Grinder is intended for grinding various types of coffee An adjusting knob with scale is used to continuously set the fineness of the grind from "Turkish fine" to "Coarse" The Coffee Grinder is suitable for use in food stores, cafés, restaurants and hotels

- كسارة الحجر الجيري اختيار مناسبة

- high performance mining equipment spiral classifier

- سعر الاسمنت في كينيا

- عودة توقف لبطانات مطحنة الأسمنت

- سنگ شکن تجهیزات سنگ مورد استفاده فک

- Raymond 82 Hammer Grinding Machine

- كسارة صخور الفحم للبيع

- استخدام هذا النوع من سحق كسارة رمل الكوارتز

- محاذاة كسارة الفك لقضيب التوتر

- Setting Up Manufactured Sand Plant

- ألواح الجبس ماكينة الصين

- كسارة حجر للإيجار في ولاية ماهاراشترا

- التعدين شركة في الهند

- gold mining machine of mining machine in ghana

- مصانع طحن الأسمنت وتجفيف الخبث

- التدريب على التعدين في الصيف

- مواصفات مكثف خام الذهب على نطاق صغير

- hot sales gold mining equipment por le crusher mobile crusher

- تستخدم المطاحن في مصانع معالجة المعادن

- آلات طحن الحجارة في الصين

- تامین کنندگان سنگ گرانیت در جوهور

- gladiator marah bs crusher

- تكلفة حصى الحصى لكل طن الهند

- كسارة الفك كبيرة الفك أولية متنقلة للبيع

- مصنع الأسطوانة مطحنة طحن

- dolomite grinding roller mill manufacturer india

- سيمون هندوراس محطة كسارة متنقلة

- آلة طحن الحجر الجيري في اليمن

- كسارة فكية صغيرة في الهند في جنوب إفريقيا

- spring manufacturers for plant

- صورة مخطط تدفق لتجهيز المخابز

- الهند، محطم النفط، وعلى نطاق صغير

- شاشة كسارة الكروم

- foundry fettling grinding machines

- کمربند فیدر نوار نقاله سنگ شکن آسیاب سیلیکا

- شركة لبيع الحجر السوداني

- سنگ زنی سنگ شکن برای سنگ آهک

- Portable Mobile Crusher For Mining And Construction

- جنوب أفريقيا المنغنيز، كسارة الفك

- سنگ شکن و تنظیم موتور

- إصلاح كسارة الفحم المحمولة في أنغولا

- crushers nigeria exporter

- مورد مصنع الرمل في الأردن

- عملية الطحن العمل

- كسارة الفحم الصغيرة

- unit operation mccabe hammer mill image

- مطحنة قرص جلدي

- طاحونة الخرسانة الماسية ماليزيا

- سعر كسارة مخروطية 20 tph تستخدم إثيوبيا

- gs vibrating screen structure catalog

- الفحم المطرقة مطحنة صيانة الشعبي

- مسابك نحاسية في السعودية

- شركات محاجر كسارة الصخور

- Machinery Involved In Quarrying Of Granite

- إدخال ومعالجة نترات الكالسيوم

- مبدأ عمل ريموند مطحنة في قوات الدفاع الشعب 8

- تستخدم آلة طحن مطحنة الكرة للبيع في المملكة المتحدة

- gold buddy highbanker demo

- پردازش سنگ معدن سرب آنتیموان

- جميع الكسارات المعدنية

- دعم جاك في صناعة التعدين

- titanium seperator from sand machine

- شراء كسارة الصابورة من العراق

- اكبر شركة في الجزائر لاستيراد قطع الغيار من الصين

- سنگ شکن مزایای

- manufacturers suppliers heav

- الأمنية المشتركة لتشغيل محطة كسارة حجر

- قطع غيار للكسارة ذروة الهند

- اندونزی تولید کننده تجهیزات معدن

- aluminium mining in guinea

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت