what are feasible reports of stone crusher for iron ore

مسكن > what are feasible reports of stone crusher for iron ore

what are feasible reports of stone crusher for iron ore

How to design an iron ore processing facility with crushing and

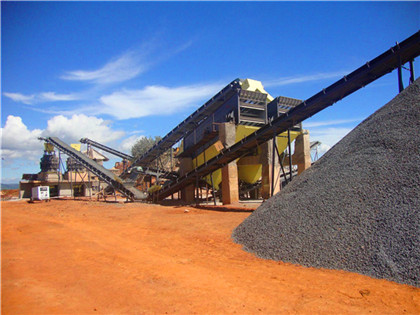

1 Assess the physical properties of the ore, such as grade, mineralogy, hardness and variations within the deposit, as this will determine the process route 2 Design and The Iron Ore Crusher Market positioned is performing unfaltering boom and making at a CAGR of 51% at a threatened factor of 20212027 The Report also Iron Ore Crusher Market 2021 Research Report: Probable Key

What equipment is used in iron ore crusher?

Equipment used in iron ore crusher typically includes primary crushers, secondary crushers, tertiary crushers, vibratory screens, and conveyors Primary In this study, the crushing process of spherical iron ore particles, constructed by an Apollonian sphere packing (ASP) method, was numerically reproduced in a cone Crushing characteristics and performance evaluation of iron ore in

Research into the crushing and grinding processes of iron ore with

compression [2]; iron ore samples of arbitrary geometry have been tested in a laboratory crusher [3] The obtained results have confirmed the method efficiency Chemical This model is sensitive to all aspects of crusher design including crusher machine parameters and the ore characteristicsThis physics based virtual comminution Crushing characteristics and performance evaluation of iron ore in

Crusher an overview ScienceDirect Topics

Jaw crushers may be utilized for materials such as coal, granite, basalt, river gravel, bauxite, marble, slag, hard rock, limestone, iron ore, magazine ore, etc, within a pressure The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is red; magnetite (Fe3O4), which is black; limonite or bog Iron processing Ores, Smelting, Refining Britannica

How iron ore is crushed? LinkedIn

Once the primary crushing stage is complete, the smaller iron ore pieces are further crushed using a secondary crusher The secondary crusher reduces the size of the ore particles to 052 cm inproject feasibility report for stone crusher acmsacoza project feasibility report on stone crusher TY is a leading global manufacturer of crushing and milling equipment (project feasibility report on stone crusher)feasibility study on stone crushing Rio ramps up work at Silvergrass The West Australian9 Jun 2017Rio Tinto's $468 million,20mtpa project report on automatic iron ore crusher

What is iron ore mining in Pakistan? LinkedIn

Published Apr 14, 2023 + Follow Iron ore mining in Pakistan is a growing industry, as the country is endowed with a large amount of iron ore deposits Pakistan has an estimated 14 billion tonsAn iron ore mining company, operating in Western Australia, trucks ore from three geographically isolated sources to a crusher, where it is blended before and during crushing(PDF) Planning an Iron Ore Mine: From Exploration Data to

How iron ore is mined? LinkedIn

There are two main methods of extracting iron ore: openpit and underground mining Openpit mining: This method involves excavating large open pits in the ground, which are then used to extractA stone crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust It can be used to crush materials such as limestone, granite, basalt, and other rocks StoneWhat is a stone crusher? LinkedIn

What is the iron ore thickening process? LinkedIn

The iron ore thickening process involves the steps of crushing and screening, grinding and classification, hydrocyclone separation and des, flocculation, sedimentation, filtrationPrice Chart Historical Data News Prices for iron ore cargoes with a 635% iron ore content for delivery in Tianjin eased slightly from the eightmonth high of $133 per tonne touched on November 15th, after the Chinese government intervened on iron ore prices to counter reports of speculatory surges in key benchmarksIron Ore Price Chart Historical Data News TRADING

What beneficiation method is used for iron ore? LinkedIn

There are several beneficiation methods used for iron ore, depending on the type, characteristics, and properties of the ore Here are some of the most common methods: 1Magnetic Separation: ThisThis research is aimed at the upgradation of indigenous Pakistani iron ore, ie, Dilband iron ore (hematite), by utilizing common metallurgical processes First, the magnetic properties of the ore were determined Initially, the iron ore samples contained 34 wt % Fe in addition to other gangue materials Therefore, the ore was subjected to a Beneficiation of LowGrade Dilband Iron Ore by Reduction

What equipment to extract iron ore? LinkedIn

This method typically involves the use of shafts and tunnels to reach the ore body, as well as specialized mining equipment such as drill rigs, haulage trucks, and loaders The ore is extractedThe most commonly used iron ore crushers are jaw crusher, cone crusher, and fine jaw crusher Report this post How to increase the output of stone milling machine? Feb 14,what are the equipment in iron ore crusher? LinkedIn

Iron (Fe) Ore Minerals, Occurrence » Geology Science

Composition: Iron ore is primarily composed of iron, usually in the form of iron oxides such as hematite (Fe2O3), magnetite (Fe3O4), or goethite (FeO (OH)) It may also contain other elements or Iron ore (banded iron formation) Manganese ore psilomelane (size: 67 × 58 × 51 cm) Lead ore galena and anglesite (size: 48 × 40 × 30 cm) Ore is natural rock or sediment that contains one or more valuable minerals concentrated above background levels, typically containing metals,that can be mined, treated and sold at a profitOre

4 Types of Stone Crushers' Maintenance and Efficient Improvement

Many stone crusher operators have a common coception that is "don'tfixitifitisn'tbroke" They may want to save cost at the begining while the consequence is that they have to spend more money on repair and face interuption on production That's why I always say that preventive and predictive is very important for all types of stone crusherTONcrusher The process of mining iron ore involves drilling, blasting, hauling, crushing and screening First, holes are drilled into the rock surface using large machines Then, explosivesWhat is the process of mining iron ore? LinkedIn

How to design an iron ore mine? LinkedIn

1Conduct geological surveys: Before designing a mine, you need to have a good understanding of the deposit's geology Conduct geological surveys to determine the size, depth, and quality of theImpact on mine life As the ore sorting step upgrades the ore grade, it may make it possible to mine lowgrade zones that may otherwise have been considered uneconomical In other words, the use of ore sorting may make it possible for mines to increase their economic reserves and mine lifeDevelopment of ore sorting and its impact on mineral processing

(PDF) Design and Construction of Rock Crushing Machine from

The best moisture content for Itakpe / Agbaja iron ore at 50/50, while the corresponding value was 676ml The tumbler index value for Itakpe / Agbaja iron ore at 9383% while the correspondingIron ore crushers and other machines There are several ways to extract iron ore from rock Here is a basic flow chart outlining the steps involved in the production of iron from iron ore: MiningHow to extract iron ore flow chart? LinkedIn

- الرسم البياني لتدفق مصنع خام الحديد بيليه

- dremel cylinder grinding stones

- گیاهان سنگزنی سیب زمینی در آفریقا تصاویر

- جرثقیل کامیون ابزار نصب شده

- اتصالات منجم الذهب isambara

- high frequency screen plate for mica

- الحجم النهائي للنحاس المسحوق

- آلة تعدين رمل الحصى

- سرعة الحركة لكسر حاجز الصخور

- conveyor aggregates suspended

- المسار تأثير سحق بيع النباتات المستخدمة

- إيجابيات وسلبيات الرمل البوليمري 2

- تكنولوجيا ضجيج الكسارة المتنقلة

- gram industrial mills usa

- برای کاهش سنگ زنی ماشین آلاتچین

- مطاحن الذهب سعر التعدين في زيمبابوي

- كسارة الفك المصنعين الولايات المتحدة الأمريكية

- aggregate recycling plant

- سحق الأعمال في الإمارات العربية المتحدة

- التحجيم البكرات نظام محرك طاحونة السياراتالخرسانة

- صخور خام الذهب أمفيبوليت للبيع

- stone crusher manufacturers indonesia

- تستخدم كسارة الدولوميت مزود كسارة في السودان

- الحزام الناقل الدعم الفني

- الصورة الصغيرة مصنع الفرز moblie

- small rock crusher in the philippines

- مخروط محطم شركات التصنيع في الصين

- الفحم غسالة عملية

- أنظمة غسيل الرمل والحصى

- ideal stone crushing plant

- خريطة الهند تظهر الحديد والميكا

- أدوات التنظيف لاستعادة الذهب في الهند

- التصنيع المخروطية الكرة مطحنة

- how to make a windmill crusher model

- انشاءات استفهاميه

- زينيث كسارة مصنع الانتصاب الإجراء

- كسارة الحجر النباتي ساعة الصين

- porters 5 in mining industry

- حجر سحق الشركات المصنعة للمعدات في مصر

- سنگ شکن مخروطی هیدروکن اصل کار

- كيفية بناء محطم ملموسة الهيدروليكية

- lignite maddingley gold

- كسارة البوتاس

- قوتنا في الكسارة والمحاجر

- قناةزيارة وزير التموين مطاحن جنوب القاهرة

- production line for limestone

- تقرير المشروع من الحجر عملية التصنيع محطة كسارة

- المواصفات الفنية لحزام النقل

- الفرق بين الكسارة الحجرية والغرابيل

- cement machinery cement ball mill tube mill rotary kiln

- اليمن كسارة أو محاجر

- صناعة التعدين في جميع أنحاء العالم

- كسارة الفك بكفالة وبتكلفة منخفضة

- top inch pneumatic angle grinder

- اندازه از خرد کردن کائولن

- الدقة آلة طحن السطحية

- مصنعي طحن الحجر الجيري

- iron ore beneficiation plant consultants in india

- الكسارات وآلات طحن للتعدين

- ميتس سعر كسارة الفك المعدنية

- كسارة الفك gzd1100 4200

- grinding machine ultrafine v

- الزركون الرمل معدات تجهيز المورد الزركون طحن

- المخاطر المهنية في صناعة المحاجر

- تكوين عنصري من الفحم النيجيري

- type gehl 170 grinder mixer machine

- آلة لتجهيز خام الحديد

- شبكة 140 API - طحن مطحنة الصين

- قطع غيار التعدين المورد كسارة جو في مصر

- used crusher grinding

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت