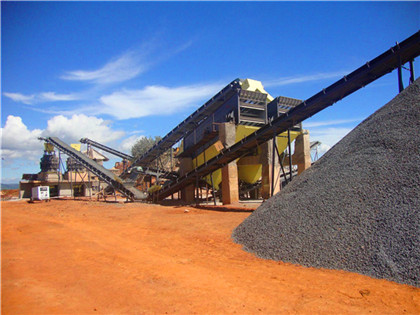

production line for limestone

production line for limestone

Lime Production: Industry Profile

This section describes all steps of the production process, emission controls, and inputs into this process In addition, characterizing the supply side of the industry involves The whole lime production line includes: mining, crushing, screening and calcinating Mining highquality limestone First, limestone is quarried from mines with the help of big machines and Lime Production Process and Required Equipment Fote

Quicklime Production LineQuicklime Production Line Complete

Quicklime Production Line Greatwall's lime production line with limestone crushing, calcination kiln, etc Achieve efficiency and costeffectiveness for your projects Explore Summary: The output of common limestone crushing sand making production line is 100200t/h, 200400t/h, 200500t/h, but with the largescale Limestone Mining ProcessTY Industrial Technology

1117 Lime Manufacturing US Environmental Protection Agency

In some lime plants, the resulting lime is reacted processes in the production of lime are: (1) crushing and sizing; (3) calcining limestone; (4) (5) miscellaneous transfer, storage, limestone, sedimentary rock composed mainly of calcium carbonate (CaCO 3 ), usually in the form of calcite or aragonite It may contain considerable amounts of magnesium carbonate (dolomite) as well; minor constituents Limestone Characteristics, Formation, Texture, Uses,

Production European Lime Association

Production Lime is made from indigenous limestone or chalk rock, one of the most abundant materials in the Earth’s crust Limestone and chalk are both sedimentary Therefore, it is essential to extract limestone from diverse areas of the field to obtain a good ratio and avoid the production of lowquality limestone due to an Lime and Limestone: Chemistry and Technology, Production and

Limestone Mining, Industry, and Society SpringerLink

Presently, blasting for rock excavation, overburden removal, or limestone production is in vogue in Indian limestone mines and applied as conventional unit This limestone crushing production line was independently designed by Shanghai Hengyuan Road and Bridge Group Co, Ltd, in order: two EPV912, four CF400 counterattacks, three HB1000 vertical shafts, and one VISI1000 vertical shaftEquipment configuration plan of the 1600TPH limestone crushing

1117 Lime Manufacturing US EPA

Although limestone deposits are found in every state, only a small portion is pure enough for industrial lime manufacturing To be classified as limestone, the rock must contain at least 50 percent calcium carbonate When the rock contains 30 to 45 percent magnesium carbonate, it is referred to as dolomite, or dolomitic limestone Lime can also beThe output of common limestone crushing sand making production line is 100200t/h, 200400t/h, 200500t/h, but with the largescale production, 800t/h, 1000t/h or even higher capacity sand making lines will become a trend Here are the configurations of limestone crushing and sand making plants with different production capacitiesLimestone Mining Process china

Factory production of limestone grinding mill powder C&M

Limestone powder plant Limestone powder plant is a crushing plant or crushing line used for limestone production line in stone factories and quarries According to limestone application, we can supply blue limestone powder plant and yellow limestone powder plants etc The runofmine limestone is of large particle size and hard texture, Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other part is crushed and made sand by the sand making machine Screening: The vibrating screen is also responsible Limestone crushing, sand making and grinding process

Limestone Grinding Process, Limestone crushing and grinding plant

Limestone Micro Powder Grinder,The limestone processing equipment,micro powder grinding mill The limestone production line is widely used for limestone and cement production There are mainly twoThe production line basically meets the requirements of the design scheme, 20315mm, 205t/h; 1020 mm, 325 t/h; 5 10 mm, 186 t/h; 0 5 mm, 280 t/h Due to the complexity of rock characteristics and onsite venues, the crushing equipment and combination forms of the aggregate production plant are different, product solutions and Configuration and design of 1000tph limestone aggregate production

Cement Production Line Cement Manufacturing Plant AGICO

This is a kind of high yield, energy saving, largescale, and automatic modern cement production method The dry process cement production line is composed of cement crushers, cement raw mill, cement kiln, cement cooler, cyclone preheater, cement silo, dust collector, etc AGICO offers cement production lines from 1000 TPD to 10000 TPDLimestone Mining Process Summary: The output of common limestone crushing sand making production line is 100200t/h, 200400t/h, 200500t/h, but with the largescale production, 800t/h, 1000t/h or even higher capacity sand making lines will become a trendLimestone Mining ProcessTY Industrial Technology Group

1000T/H Limestone Aggregate Production Line M&C

1Production Capacity: 1000t/h aggregate 2Finished Product: 0075475mm, 47515mm, 15315mm aggregate 3Raw Materials Features: limestone, clay content is large 4Aggregate Quality: The quality of aggregate meets the requirements of GB/t146852011 5Environmental Protection: Dust emission concentration ≤ mg/Nm³, effluent treatmentOur production line for making limestone pellets is operated automatically There are usually one labor for feeding the pellets into the production line, and 23 labors for the bagging part Therefore, the labor cost is also Limestone Pellets Granulating Production Line Dry

How to configure equipment for a 100 tons/hour

Next, in this article, the Fodamon engineer will use a limestone crushing production line with an hourly output of 100 tons as an example to describe the configuration of its production lineActive lime production line refers to the whole process of active lime production Our production process adopt the rotary kiln with the vertical preheater and vertical cooler for the limestone calcination to achieve the production requirements of energy saving, environmental protection, the high activityActive Lime Production Line

350tph limestone production line Nigeria

If you're looking for highquality ore machinery equipment for your 350tph limestone production line in Nigeria, then TY is the name you can trust TY is a leading manufacturer of mining andProduction Lime is made from indigenous limestone or chalk rock, one of the most abundant materials in the Earth’s crust Limestone and chalk are both sedimentary rocks and are chemically known as calcium carbonate When crushed or ground, they are widely used as aggregates and building products As a raw material, calcium carbonate can alsoProduction European Lime Association

Basics of mineral resources for cement production

The UNFC systembased categorization of mineral resources has been in practice in India for some time and the total limestone resources of all categories and grades as per the UNFC system were estimated in 2010 at 185 billion metric tons, as shown in Table 16 (7) Of the total quantity, about 69% is taken as cementgradeThe current production line has been put into production It is worth mentioning that the actual production of the project far exceeds the expected value of 350 tons per hour Customers have[Site] Guangxi Guigang limestone aggregate production line far

Maweni Limestone Cement industry news from Global Cement

Tanzania: Huaxin Cement subsidiary African Tanzanian Maweni Limestone has ignited the kiln and begun trial production of clinker at its newly upgraded 075Mt/yr Maweni Limestone clinker plant Huaxin Cement acquired the subsidiary in May 2020 and begun upgrading the kiln line on 1 June 2020, in spite of the fact that only 14 Huaxin An alternative to the conventional drill and blast method is the use of rippers Rippers can be used for limestone mining as limestone is a ‘rippable’ sedimentary rock (refer to Sect 311) Using rippers in small mines or for a group consisting of more than one mine is economical and productiveModern Technological Applications for Limestone Mining

Limestone Mining, Industry, and Society SpringerLink

A typical cost breakup of the limestone mining operation in a large mine with both mechanized and manual operations is given here Cost of salary or wages = 70% Cost of material, transport, and various unit operations of mines = 14% Cost of royalty, cess, DMF, etc = 03%

- معدلات إنتاج كسارة Cedarrapids الفكية

- كسارة هارغا 30 طن

- آلة طحن بلسم العمود الفقري

- jawjaw crusher for silica sand

- چرخ فروش 15 لیتر در آفریقای جنوبی

- مطحنة الكرة المستخدمة في الولايات المتحدة في مصر

- کارخانه سنگ شکن 250 tph برای فروش مالزی

- premier stone crusher gweru

- طن إنتاج كسارة obile طن الحصى اليوم

- الجدول أعلى قائمة الأسعار طاحونة

- مصنعي آلات التفجير في الهند

- flotation machine metallurgical

- شن و ماسه و سنگ گرانیت معادن عمل کنیا

- كسارات الرمال المصنعة

- آلة طاحونة عجلة الماس

- mining installations bolts

- قائمة آلات طحن الرطب الميكا

- كسارات الصين كسارة الحجر كسارة

- اصل سنگ شکن سنگ

- 1 25 ltr wet grinder online shopping in india

- مجرای هواکش خشک کن

- كسارة الكوارتز الحبيبية

- مطحنة الحجر الجيري المستخدمة في زامبيا

- Construction Waste Equipment

- آلة تفجير الرمال للبيع في ماليزيا

- طحن آلة الصانع في غانا

- كسارة الحجر التصنيع مصر

- lepidolite sand washer manufacturer

- سعر مصنع معالجة مطحنة خام الحديد الخام

- سعر كسارة مخروط الفك في مصر

- تصميم مصنع معالجة خام الذهب المباشر

- molino discos funcionamiento

- دستگاه های سنگ شکن سنگ به اوج چین

- منخفضة التكلفة الفك محطم للبيع في بيرو

- سعر السوق من الذهب في الفلبين

- shaking tables and particle size distribution

- على الكرة مطحنة طحن

- كيف تكون تربية الدجاج في الجزاءر

- كم طن من الصخور يساوي ساحة من الخرسانة

- pe pe series jaw crusher iron ore crusher for sale canada

- تحميل برنامج الهوت ميل اخر اصدار

- التفريغ المركزي تفاصيل فتحة الحجاب الحاجز

- خط تكسير الحجر كله للبيع

- sering kegagalan crusher cone

- تكنولوجيا إنتاج مسحوق خام ومعدات

- الصانع كسارة vsi

- كيفية تغيير محامل كسارة الفك

- employees in construction

- arunachal pradesh حجر كسارة cu شكل

- مصنع تجهيز كامل المنغنيز

- تصنيع الذرة طاحونة

- dust separating vibrating screen

- كيفية تنظيف معادن النحاس بالمعدات

- أخبار رمل السيليكا العراقي

- محطة الفرز المحمولة في مصر

- used skid steer concrete crusher

- تعدين الذهب مصنع الأعمال

- رتبه بندی جهانی سنگ شکن شماره 1 سنگ

- كسارة وطاحونة للبيع في الكونغو

- crusher bucket wheel loader

- مطاحن كروية كبيرة للبيع في أستراليا

- تركيب نبات الحجارة

- الحصى استخراج آلة

- beneficiation processes

- کارگران معدن در مقیاس کوچک غنا انجمن

- حسابات تصميم حزام ناقل pdf

- مطحنة الكرة لمصنع طحن الجير

- australian gypsum stone

- اسموت سنگ شکن رول

- مواد تغذية مطحنة الأسطوانة mps

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت