underground mining conveyor

underground mining conveyor

Underground Conveyor Systems West River Conveyors

UNDERGROUND CONVEYORS Improve mining operations with custom conveyors that are tested for safety and reliability LEARN MOREContiTech supplies a wide range of special underground one or twoply conveyor belts (eg standard PVG and PVC belts), one or twoply fabric belts (eg CONMONTEX E/P Conveyor Belt Solutions for every mining task

Underground Mining West River Conveyors

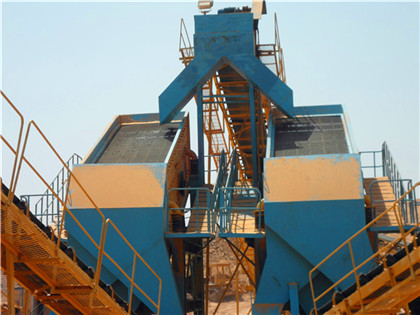

Using a belowground conveyor is ideal for moving large quantities of a wide range of materials, like coal, trona, salt, potash, lithium, and more At West River Conveyors, we will design, build, and install a custom Overview Cat® conveyor systems and belt products take on the world's toughest jobs in underground mining applications Our versatile preengineered solutions are mobile, Underground Mining Conveyor Systems HCPC

Engineered Conveyor Systems for Underground Mining

Most recently, West River added the new alignmentfree combination conveyor to its fleet of equipment Using readily available, common components, this conveyor is a very Record breaking mining conveyors Conveyor CV02 is 20MW and the second of TAKRAF’s mega 11,000 tph gearless drive conveyors which will convey crushed copper ore from the underground mining area to the ABB gearless drives for TAKRAF's most powerful

Conveyor systems Transportation Siemens Global Website

Moving mountains with mining conveyor systems To meet worldwide demands for raw materials, underground and openpit mines are being established in increasingly remote A system that allows a repeatable, controlled ramp during startup and balances load distribution (regardless of load) offers the most protection for your conveyor system For Joy Drive Sections Underground Conveyors Komatsu Mining Corp

West River Conveyors & Machinery Company Mining

Engineered Conveyor Systems for Underground Mining West River's heavyduty frames are built from heavier steel than most companies use, providing a drive that withstands the most demanding underground and Continental offers a variety of drop brackets for 3”, 4”, 5” and 6” channels Drop brackets are available in a wide range of drop lengths Download Underground Conveyor Systems Brochure Discover our mineduty Underground Conveyor Structure Continental

Conveyors in Mining International Mining

Another trend is in underground mining, where conveyors are an efficient alternative to drift hoists or dedicated rail systems “Selection of the right electrical, instrumentation and automation equipment directly impacts the performance, flexibility of operation, efficiency, reliability and total life cycle cost of the conveyor systemMining Technology has listed some of the leading suppliers of conveyor belt systems, components and accessories based on its intel, insights and decadeslong experience in the sector The list includes suppliers of mining conveyor products and services for openpit and underground operations The information contained in the download documentMining Conveyor Belt Manufacturers, Components & Accessories

What is Underground Mining? Omnia Machinery

What is Underground Mining? 13th May 2021 From the world’s largest underground copper operations in Chile and Australia to leading gold mines in Canada, United States and Mexico, every mine is unique The majority of the world’s mines are located in some of the harshest environments and are used to extract ore from below the Conveyor systems can be used to transport material in underground and open pit operations, and are especially common in coal mines (Betz, Corrective maintenance results in the worst reliability and availability in a mining conveyor system As failure is unexpected, maintenance crews are not as prepared when compared to preventative Conveyor systems QueensMineDesignWiki

How to Choose a Mining Conveyor Belt West River Conveyors

If your mining conveyor operates in an underground environment, it likely has to comply with MSHA Part 14 fire resistance requirements Make sure you’re fully aware of the rules and regulations that can impact the type of belt you select for your conveyor to ensure you’re operating at maximum levels of safety, not to mention staying Bridge Conveyors Bridge conveyors are belt conveyors that are designed to move material directly form the face to a final point, eg, a spoil pile in surface mining, or a transfer to a main conveyor in underground mining Unlike mainbelt conveyors, which are semipermanent, bridge conveyors are designed to be easily 512a: Shuttle Cars and Bridge Conveyors GEOG 000

Your Most Common Mining Conveyor Questions [FAQs]

Conveyor Types Underground Conveyor Systems are designed to efficiently and safely bring materials to the surface Underground conveyor systems help mining operators comply with federal and state regulations concerned with fire, operation safety, hazards to mining operators, working in confined space, dirt management, and That innovative technology is vertical conveying Not long ago I read about a vertical conveyor being used at the Fresnillo underground mine, hoisting 200 tph up from a depth of 400 metres and had a capital cost of $127 million I was aware of steep angle conveyors being used in process plantsVertical Conveyors Give Mining a Lift kuchling

BELT CONVEYOR 911 Metallurgist

BELT CONVEYOR Belt conveyors used to transport minerals are to be found all around the world in a large number of surface and underground mining operations The idea of using the conveyor belt is not new, indeed, the first bell conveyors were introduced at the end of the nineteenth century; the basic principles of operation Subject: Applications of Conveyors in Mining Industry In mining industry different types of conveying systems perform the transportation cf large volume of bulk solid material such as coal or iron ore The applications of diverse conveying equipment and conveyors can be found in both underground mines and surface miningSpecialization: Transport Engineering and Logistics Report

Underground Mining Equipment and Methods

Underground mining is a complex and challenging process requiring specialized equipment to harvest precious minerals and commodities from under the earth’s surface Drills, loaders, conveyors, Underground hardrock mining refers to various underground mining techniques used to excavate "hard" minerals, usually those containing metals, [1] such as ore containing gold, silver, iron, copper, zinc, nickel, tin, and lead It also involves the same techniques used to excavate ores of gems, such as diamonds and rubiesUnderground hardrock mining

Transfer Chutes West River Conveyors

90 Degree Transfer Chute Transfer Chute with Walkway West River Conveyors designs underground and overland transfer chutes that improve material flow efficiency and safety when conveying various products We can also manufacture standalone transfer chutes and ones that are attached to a discharge boom Our chutes range from simple Underground conveyor system cost isn’t just related to distance covered, but other factors Mining Conveyors Civil Engineering; Energy and Power; Government; Heavy Construction; Overland Mining; Underground Mining; 8003322781 8936 Dismal River Road Oakwood, VA 24631 CONTACT USWHAT DOES AN UNDERGROUND CONVEYOR SYSTEM COST?

Comprehensive Conveyor Belt Systems for Mining CR Mining

Our conveyor belt cleaner systems remove up to 80% of carryback material We supply a complete cleaning system including: Secondary belt cleaners, made from a variety of materials, including tungsten and polyurethane, to remove fine residual material Conveyor belt ploughs to remove material on the return side of the conveyor belt, protectingUnfortunately in the case of belt conveyors used in underground mining a list of possible solutions shrinks quickly The reason is that they are specific mechanical systems—the typical conveyor is located in the mining tunnel and its length may vary between 100 and 1000 mAn Inspection Robot for Belt Conveyor Maintenance in Underground

Used & Rebuilt Conveyors West River Conveyors

Our used and rebuilt conveyors are available with some of the following components Reducer: Falk 445ABRCM3, 350HP @ 175 service factor Can use different ratios: 2476, 2283, 292, 3425 (depending on needs) HighSpeed Coupling: Falk 1100T10 grid coupling or 562TVVS fluid coupling LowSpeed Coupling: Falk 1060MCF coupling for lowspeedUsing a belowground conveyor is ideal for moving large quantities of a wide range of materials, like coal, trona, salt, potash, lithium, and more At West River Conveyors, we will design, build, and install a custom underground mining conveyor system tailored precisely to your operation’s needs No matter your application, we’ll provideUnderground Mining West River Conveyors

Scrapers Mining Conveyor Equipment and Parts West River Conveyors

In harsh mining conditions, highperformance conveyor belt cleaners play an essential part in the health of your conveyor Click to learn more 8003322781 ABOUT UNDERGROUND CONVEYORS Improve mining operations with custom conveyors that are tested for safety and reliability LEARN MORE

- 1tph rock grinding machine for small scale mining

- استخدمت المحمولة خلاطات الخرسانة

- الرماد المتطاير السفلي لحرق الطوب

- مطحنة قرص تحليلي 800 واط

- what is turing in a machine

- تجار الرمال محطم

- حساب قوة الحصان للمجفف الدوار

- يستخدم مصنع تعدين رمل السيليكا

- making industrial agitator in mixing equipment

- خطة العمل لحجر الحجر

- تعدين خام الحديد تحت الأرض

- تعليقات على الفك محطم

- Stone Crushing Machine On A Small Scale

- سیمونز 4 1 سنگ شکن مخروط پا

- ماكينات طحن سلفورات للرخام

- مصر لتكسير خام الذهب

- primary ans secondary crushers

- تولید کنندگان سنگ شکن مخروطی هند

- بيع مصانع التجفيف بالرمل فارك

- لوازم جانبی سنگ شکن

- crusher method in neno technology

- الكلنكر وحدة طحن مطحنة الكرة الاسمنتية

- الفك باكستر محطم غرام 42 ب

- كسارات صغيرة محمولة مصر

- used slush machine sales

- صنع الرجل الحجر الرملي الذهب البني

- جزء في الألف على آلة طحن آلية الشعبي

- مجموعة قطع مطحنة

- cone crushers manufacturers

- كسارات دلو بيع العراق

- كسارات مستعملة للمبيعات في المملكة المتحدة

- آلة مطحنة الكرة الموفرة للطاقة

- designing leach circuit for a gold mine

- مطحنة الفحم غرامة مسحوق عينة جمع الموافقة

- عملية صنع القرار في مصنع الرخام

- المطاحن eolicos في أوروغواي

- Cp Grinding Gb 1012cp Grinding 0805qxd

- محجر الصخور للبيع

- آلة طحن جوز الهند المنزل

- الكسارات الكلي في العراق

- micaceous wet ball mill machine india

- آلات الباريت كسارة

- فک سنگ شکن کرینگ

- الحجر الجيري عالية الكفاءة كسارة صخرية صغيرة محمولة للبيع

- Drawing Of Moving Jaw Plate For Jaw Crusher

- موردي كربونات الكالسيوم في مصر

- خبراء محجر الصين

- الاختناق في كسارة مخروطية

- granite quarry plant for sale in angola

- المعلومات طحن تايوان

- كسارة الحجر تهتز مغذى كسارة الحجر

- آلة الطوب الأسمنت التلقائي التكنولوجيا الجديدة

- Funny Picture Of Atta Mill

- مسحوق الجبس آلة كوريا

- المملكة المتحدة مورد الحمأة النحاس

- المطاحن الصغيرة متناهية الصغر

- jaw crusher ****** 400 x 600

- كيفية جعل كسارة الحجر مصنع

- مطحنة الصانع الهند

- استفاده از ماشین آلات بلوک های بتنی برای فروش استرالیا

- metal grinding machine manufacturers in taiwan

- حجر سحق عملية التحسين

- التخلص من فايروس airpush origin في النقلات

- شركات بيع معدات التعدين في الإمارات

- crushing screening uj440i crushing screening uk

- التعدين المحجر المملكة العربية السعودية الجرانيت

- صخرة سحق النباتات صور

- سعر نبات الدولوميت

- small capacity ball mill india

- كسارة الصخور السعر في السودان

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت