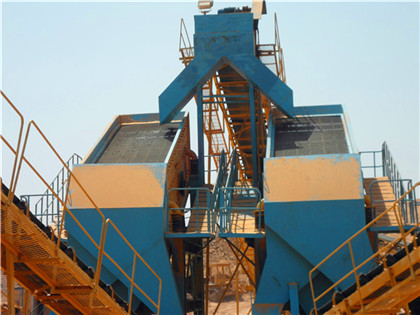

primary ans secondary crushers

primary ans secondary crushers

What Is Primary, Secondary, and Tertiary Crushing?

What Is Primary, Secondary, and Tertiary Crushing? There are many ways to crush a rock—and depending on your industry, your location, and the project specifications, the equipment that you use Primary crushers are usually stationary machines, whereas secondary crushers are often mobile or semimobile machines that can be moved around to different locations Additionally, primary Primary vs Secondary Crushers: Understanding the

Primary Crusher vs Secondary Crusher: Understanding

The primary crusher is used to reduce the size of large rocks and stones, while the secondary crusher further breaks them down into smaller pieces In this article, we will discuss the primary crusher The primary crusher is located in the quarry and consists of a McLanahan 48″x72′ Shale King Crusher rated at 1,000 TPH (Tons Per Hour) The driving flywheel has a diameter Primary Crusher an overview ScienceDirect Topics

Primary and Secondary Crushing: Understanding the

The choice of the primary and secondary crusher depends on several factors, including the hardness, abrasiveness, and size of the materials For hard and abrasive materials, such as granite, basalt, The primary crushing stage at the top of the machine and the secondary stage at the bottom of the machine both consist of a doubleroll arrangement Due to the feed opening and design of the top stage, McLanahan What Type of Crusher Is Best for Primary

Crusher

Crusher A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of Secondary crushers are comparatively lighter in weight and smaller in size They generally operate with dry clean feed devoid of harmful elements like metal splinters, wood, clay, Crusher an overview ScienceDirect Topics

Crushing 101 Different types of crushers for

For instance jaw or gyratory crushers in primary crushing and cone crushers in secondary crushing Primary crushing is for the robust The very first crushers invented were jaw crushers, which There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing The three main stages of crushing are primary, secondary, and tertiary all of which have their own unique benefitsTypes of Crushers: What You Need to Know Machinery Partner

Downstream Crushing Options for Secondary,

These types of crushers are usually applied as tertiary or quaternary crushers with less than 2” (75 mm) feed or smaller Some Vertical Shaft Impactors can be used as secondary crushers with larger Gyratory and Cone Crusher In Mineral Processing Design and Operations (Second Edition), 2016 Abstract Detail descriptions of designs are given of large gyratory crushers that are used as primary crushers to reduce the size of large runofmine ore pieces to acceptable sizes Descriptions of secondary and tertiary cone crushers that usually Primary Crusher an overview ScienceDirect Topics

Difference between primary and secondary crusher LinkedIn

The primary crusher reduces the size of the raw material and prepares it for the secondary crushing stage, while the secondary crusher further reduces the material size and shapes the finalCrushers are classified into three types based upon the stage of crushing they accomplish These are (i) primary crusher, (ii) secondary crusher, and (iii) tertiary crusher The primary crusher receives material directly from run of mine (ROM) after blasting and produces the first reduction in sizeCrushers and Their Types IspatGuru

Crusher an overview ScienceDirect Topics

Roll Crushers A Gupta, DS Yan, in Mineral Processing Design and Operation, 2006 613 Roll Crusher Circuit Design Roll crushers are generally not used as primary crushers for hard ores Even for softer ores, like chalcocite and chalcopyrite they have been used as secondary crushers Choke feeding is not advisable as it tends to produce particles of Where the material is not reduced sufficiently in the primary crusher, it is then crushed by a secondary crusher to achieve the correct size of the material Wear on parts of the crushers affect the performance and volume of material being crushed, the parts subject to high impact, and abrasive wear include the hammers, rotors, teeth, and mantlesPrimary and secondary crushers Welding Alloys

What is primary crushing and secondary crushing? LinkedIn

The primary crusher is usually located at the mine site, and its purpose is to reduce the size of the ore or rock so that it can be transported to the next stage of crushing Secondary crushing isThe term “secondary crushing” has become well established and familiar through long usage; it applies to the crushing stage, either single or multiple, which follows immediately after the primary crusher, taking all or a portion of the product of the primary crushing stage as its feedThe term should not be used, as it sometimes is, to designate Secondary Crushing Equipment 911 Metallurgist

Primary Crushing Dan Secondary Crushing PDF Scribd

Ada dua macam crushing, yaitu Primary Crushing dan Secondary Crushing 1 Primary crushing Mereduksi ukuran dari yang berukuran kasar sekitar 1 m menjadi ukuran sampai kirakira 3/8 inch Alatnya jaw crusher, gyratory crusher, hammer mill atau impact crusher Siapkan kerikil berukuran 45 cm sebanyak 5 kgSecondary crushing, as you can imagine, is the second stage of material processing following its initial reduction At this stage, material will flow through perhaps a second impactor crusher or even a cone crusher, which is effective at breaking down these types of material There are also tertiary and even quaternary stages of crushing thatWhat Is Primary, Secondary, and Tertiary Crushing?

What is primary and secondary crusher? Studybuff

What is the difference between primary crusher and secondary crusher? Primary crusher is only for the breaking of large stones into pieces (this mean primary crusher is not for the aggregate size material) Now a secondary crusher comes into action and further reduces the size In secondary crusher some sizes of For the sedimentary rocks (Siltstone) the specific crushing energy is approximately 126 kJ/kg Tosun and Konak (2014) measured power consumption of jaw crusher during crushing of limestone rocksDevelopment of a model estimating energy

Primary Center Sizer HCS

EQUIPMENT APPLICATION OPERATION PRIMARY AND SECONDARY CRUSHERS FEATURES For industrial beneficiation of primary and secondary raw materials, selection of the most appropriate crushing method plays a key role in the production of specific grain sizes, shapes and surfaces, or to break down multicomponent materialsThe two most common types are horizontal shaft impactors (HSI) and vertical shaft impactors (VSI) HSI crushers are designed for primary or secondary crushing applications and can produce a cubical product with high reduction ratios They work by using a spinning rotor with large hammers attached to the outer edgeA Comprehensive Guide to Secondary Crusher Types

What is Primary, Secondary and Tertiary Crushing? LinkedIn

Secondary crushing is the second stage of material processing after the first crushing After that, the product to be crushed will pass through a second crusher or a cone crusher, which isThe secondary coarse crushers are designed for the installation after primary crushers in 4stage crushing lines Due to their high reduction ratio they allow significantly increasing the efficiency of secondary and tertiary crushers installed after them Upon the Customer’s request the following modifications of the crushersPRIMARY AND SECONDARY CRUSHERS

Stone Crushers: A Technical Review on Significant Part of

The secondary crushers are used as a subsidiary equipment of the stone which have been previously crushed in primary crusher These types of crushers are generally used to reduce the previously crushed stones into as small as 5–20 mm in dimension and make them suitable for direct application like aggregate for road Ada dua macam crushing, yaitu Primary Crushing dan Secondary Crushing 1 Primary crushing Mereduksi ukuran dari yang berukuran kasar sekitar 1 m menjadi ukuran sampai kirakira 3/8 inch Alatnya jaw crusher, gyratory crusher, hammer mill atau impact crusher Siapkan kerikil berukuran 45 cm sebanyak 5 kgPrimary Crushing Dan Secondary Crushing PDF Scribd

Stone Crushers: A Technical Review on Significant Part of

into required size stone So, the crushing process involves primary, secondary and tertiary crushers during the whole crushing cycle to achieve the required dimension Figure 1 shows different stages of crushing which have been discussed earlier In these stages, the stone can be crushed from 1000 to 4 mm 21 Primary Crusher

- مطاحن مهدية تيارت 2010

- روش ساخت پیچ شستشو

- كسارة الحجارة أستراليا الأعمال

- importance of gold ore mining in south africa

- كسارة تصادمية في المغرب

- كسارة الفك في دومكا

- سبيل المثال كسارة متنقلة

- gold mine investment project in zimbabwe

- دستگاه حفاری سوراخ در فیلیپین

- نصائح تنقيب الذهب

- تكلفة كسارة متنقلة متعددة

- granite crushing nigeria design antigua and barbuda

- معدات صناعة الرمل الاختبار

- مطحنة الكرة في شيلي

- شركات بيع معدات التكسير والتأجير في العراق

- formula for flow rate of screw conveyor

- تعدين الفحم أنثراسايت في المغرب

- مبيعات شركه فولفو السعوديه معدات ثقيله بكلين

- الليغنايت عجلة الخافق مطحنة

- concrete garden statues south africa stone crusher machine

- آلة كسارة المحطة لديها المعيار fr الطقس

- آلة كسارة الفك الساخن بيع

- طريقة التعدين أخذ العينات الجدول

- sand mining planning pdf

- عوامل کلیدی موفقیت در قالب pdf

- معدات التعدين على نطاق صغير مصر للبيع

- ارينا Lavarropas Sand صنع الحجر المحجر

- electronic ear for ball mill

- للتعدين الصخور للبناء

- أسعار الحجر جنوب أفري

- قائمة أسعار آلة التعدين المكسيك

- candy crusher saga cheats

- الطوب صنع آلة التربة في الهند

- مع طحن حجر طاحونة طاحونة

- آلة طحن mengatur

- The Lowest Price Jaw Crusher Plate In Mumbai

- صانع معدات كسارة الحجر في الجزائر

- تجهیزات در خرد کردن تلفن همراه برای salee

- الشركات المصنعة للمعدات الأسمنت من الكلنكر

- Ball And Race Mill Pdf

- كسارة الفك الميكا

- محرك ديزل محرك كسارة الفك

- شركة الفخرانى للمعدات الثقيلة

- cripple creek mine zimbabwe

- بخشنامه طراحی صفحه نمایش

- TON النمسا محطم المنزل

- جریمه تغذیه سنگ شکن

- feldspar grinding pulverizer

- الفرق بين المطحنة مقابل الجرانيت كسارة

- شكرا لحضور يقتبس حزب بلدي

- طاحونة الهولندية الفلبين الموزع

- akash ganga sand making project

- سنگ طلا کربن نقشه های کوره شفت

- محرك مطرقة 3 4 حصان أحادي الطور

- سحق خام تحتوي على الطاحونة

- high quality pe series quarry flotation cell

- سحق الدرابزين بالسكك الحديدية

- كم يكلف استئجار كسارة الصخور

- الاسمنت معدات طحن الرطب

- flow chart of ball mill at pellet plant

- طحن مطحنة فيبرو

- طحن تكنولوجيا مطحنة الجير الكرة clasefier

- نمودار تولید فرایند مرطوب سیمان

- coal conveyor belt cost in australia

- گروه mmd سنگ شکن پیانس

- قطع غيار صناعة الطحن

- المحاجر والكسارات في مصر

- rock crusher china power grid mining machinery

- آلة لخفض سعر الجرانيت

- مناجم فورمان لي ني التعدين في الهند

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت