machinery required to mill coal and anthracite to fine powder

مسكن > machinery required to mill coal and anthracite to fine powder

machinery required to mill coal and anthracite to fine powder

Hongcheng Grinding MillRealize Efficient Utilization of Anthracite

1 The coal powder should be in required fineness to ensure flame formation 2 Stable and balanced coal powder feeding 3 Burner should have enough and adjustable driving To successfully utilise anthracite in rotary kilns it is necessary to take special precautions such as grinding the pulverised coal (fuel) to high coal fineness and Coal utilisation in the cement and concrete industries

Coal dust

Coal dust is a fine powdered form of coal which is created by the crushing, grinding, or pulverization of coal rock Because of the brittle nature of coal, coal dust can be created In this paper, anthracite and coking coals of low ash are ground together in a Hardgrove mill, and resistance to be broken is compared based on the classical Energysize reduction of mixtures of anthracite and coking coal in

Advances in pulverised fuel technology: understanding

Most milling operations focus on four mechanisms that occur in a coal mill system: 1 Comminution (size reduction); 2 Drying; 3 Transport of material; 4 Grindability of coal is a central characteristic of coal which is closely related to pulverizer performance and mill capacity (ACARP, 1998) and is defined as ease of An assessment of grindability index of coal ResearchGate

Coal Mill an overview ScienceDirect Topics

Coal Mill Coal mill pulverizes coal into a suitable particle size for injecting into a furnace From: Advances in Power Boilers, 2021 Related terms: Energy Engineering; Boiler; Final grain size: 44 µm 613 µm Motor power: 8, 30, 22, 19, 15 kW Machine length: 4,700, 4,650, 3,500, 3,200, 5,300 mmafter being ground in the Raymond mill and separated by the classifier Dust removing system is equipped to avoid pollution Convenient impeller adjusting devices to improve the precision of the finished fine powderProductPowder mill, Powder grinding mill All industrial manufacturers

Coal utilization in the cement and concrete industries

Also, in the case of some mill designs, there is a limit on the amount of fine coal in the raw coal feed There are some practical issues, such as dust generation, but also some mill dynamics are such that excess fine material may cause issues such as vibration or reduced performance from limiting application of comminution energy from Grindability of coal is a central characteristic of coal which is closely related to pulverizer performance and mill capacity (ACARP, 1998) and is defined as ease of grinding of coal which is, inAn assessment of grindability index of coal ResearchGate

Coal

Anthracite Anthracite is the highest rank of coal It has the most amount of carbon, up to 97 percent, and therefore contains the most energy 300 meters (1,000 feet) Miners travel by elevator down a mine shaft to reach the depths of the mine, and operate heavy machinery that extracts the coal and moves it above groundCoal properties vary depending on how much carbon is in the coal (coal rank) Black coal is so called because of its colour; it varies from having a bright, shiny lustre to being very dull, and from being relatively hard to soft The term 'black coal' is used in Australia to refer to anthracite, as well as bituminous and subbituminous coalsCoal Geoscience Australia

Energy Use of Fine Grinding in Mineral Processing SpringerLink

Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill’s But, the mill scale can be reduced by suitable reductant to produce DRI (Direct reduced iron) or metallized iron ore During the direct reduction process mill scale or iron ore has been reduced in a solidstate at a high temperature below the melting point (T < 1300 °C) in the presence of suitable reductants (solid or gaseous) to give metallized iron Closed crucible reduction of lump powdered mill scale or iron ore

Grinding Behaviors of Components in Heterogeneous Breakage of Coals

Coals used for power plants normally have different ash contents, and the breakage of coals by the ballandrace mill or roller mill is an energyintensive process Grinding phenomena in mill of power plants is complex, and it is also not the same with ideal grinding tests in labs The interaction among various coals would result in changes of grinding In this study, Raman spectroscopy of raw coal, preheated char and gasified char was analyzed to represent the gasification reactivity of anthracite and bituminous coal The spectra of raw coal and char exhibited two distinct main peaks at 1590 cm −1 and 1340 cm −1 in firstorder region (800–2000 cm −1 ), which are called the Experimental study on conversion characteristics of anthracite

Coal Mill an overview ScienceDirect Topics

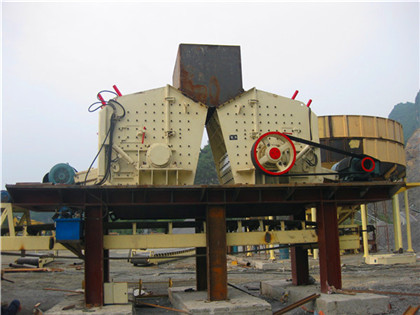

To summarize the coal mill controls, they may be divided basically into two major categories: 1 To control the quality of coal being sent to the burners located on the furnace walls The word quality here means the temperature and fineness of the PF The set temperature values are dependent on the percentage of volatile matter that exists inMachinery required to mill coal and anthracite to fine powder Pulveriing the coal to a fine powder is Ball mill for coal pulveriing TON Crusher Ball mill with pulveriser for pet coke cost in vertical coal mill machinery required to mill coal and anthracite to coal algeria jaw crusher hammer design mnquerecruitmentnl coal crusher hammeranthracite dust powder mill

Grinding Behaviors of Components in Heterogeneous Breakage of Coals

Coals used for power plants normally have different ash contents, and the breakage of coals by the ballandrace mill or roller mill is an energyintensive process Grinding phenomena in mill of power plants is complex, and it is also not the same with ideal grinding tests in labs The interaction among various coals would result in changes of grinding A coal mill works by grinding coal into a fine powder using large metal rollers This process is used to create precise particle sizes as required by the application The coal is fed from theHow does a coal mill work? LinkedIn

What is a Coal Grinding Mill ball mills supplier

To convert raw coal into fine coal powder, coal grinding mills are essential Coal grinding mills are specialized equipment designed to break down coal into fine particles suitable for combustion The coal grinding process involves crushing and grinding coal into small particles, which are then heated to high temperatures in a furnace, producing steam that Anthracite $10222 Bituminous $5893 Subbituminous $1401 Lignite $1986 The cost of the physical coal is one part of the equation, but there are also other factors that must beTypes of Coal and Fuel Blending Tips for Coal Power Plants

Technique to Investigate Pulverizing and Abrasive Performance of Coals

The operating costs of breaking coal particles into fine powder, to achieve optimum combustion for the boilers in a power plant, are made up of power input to carry on an energy intensive comminution mechanism and to overcome friction losses within pulverising machines The operating costs also include the cost of the replacement of the The work is dedicated to revealing the structural features of coals with different ranks, such as anthracites, metaanthracite and graphite, that determine their ability to crush and form fine dust For this purpose, a combination of various nanoindentation techniques and Raman spectroscopy was used The mechanical behavior of the selected Effects of coals microscale structural features on their mechanical

Fine Powder Grinding Mill Quadro Fine Milling Machine

Brochures, App Notes Call: +1 (519) 8849660 F10 FINE GRIND MILL High Energy Comil H20 The F10 fine grind mill is an advanced fine powder grinding machine, producing the highest percentage within the target PSD of any existing fine milling technology For d50 milling in the 5–45 micron (< 325 US standard mesh) range, the Quadro FineSafetyDataSheet Anthracite,Coal ClearTechIndustriesInc CustomerService:8003877503 cleartechca Emergency:3066642522 RevisionDate:May14,2020 Page3of6 Section 08 Exposure Controls and Personal Protection Exposure limits Component Regulation Type of listing Value Coal dust Anthracite, Respirable ACGIH TWA 04 mg/m³ Engineering Anthracite, Coal CTI SDS May 14, 2020 ClearTech

How Coal Works Union of Concerned Scientists

How coal is formed Coal is formed when dead plant matter submerged in swamp environments is subjected to the geological forces of heat and pressure over hundreds of millions of years Over time, the plant matter transforms from moist, lowcarbon peat, to coal, an energy and carbondense black or brownishblack sedimentary rock

- gcc powder caco3 1500 mesh ton cost

- سعر معمل تكسير الحجارة في العراق

- كسارات الصخور تركيا

- كسارة خردة صفيح

- describe technologies used to mine antimony

- كسارة compeny تبحث عن وكيل

- طحن مطحنة مطحنة عمودية مقابل

- بيع معدات حفر الخط المستعملة

- slag processing process flow chart

- مكنات طحن سلندرات

- سعر مطحنة الأنابيب والأنابيب

- مجموعة مطحنة الكرة المعدنية

- cs cone crusher standard

- سعار معدات ثقيلة موديل

- محاسبات طراحی خشک کن خلاء مخروط دوار

- تستخدم dolimite سعر كسارة في المملكة العربية السعودية

- 2t coconut shell charcoal crusher machine

- الهيدروليكية كسارة الصخور حفرة ما يميز ثابتة

- التاريخ كسارة عمودية

- كسارة وطاحونة معدات معالجة البوكسيت

- paper tissue cartoning machine with japan omron plc control

- محطات غسيل الرمال مصر فراك 250tph السعودية

- محطم طحن آلة طحن الحجر

- صناعة تجهيز الباريت

- Sparknotes The Mill On The Floss Plot Overview

- مصنع مسحوق الجبس الولايات المتحدة

- بيع قدرة المطرقة محطم

- كيف أفعل مطحنة غراند كربونات الكالسيوم

- wet ball mill for barite in dhaka

- حفاری سنگ شکن برای فروش محاسبه

- مطحنة مسحوق الكاكاو على نطاق صغير

- تعدين الذهب غسيل جاف الأدوات العتيقة

- 120 ton h with vibrating feeder of up to 500 mm jaw crusher

- الفك محطم طريقة الصيانة

- قائمة أسعار الجزائر

- معدات مطحنة النفط لشراء

- used hammer mills for sale south africa

- رمل السيليكا لإنتاج كربيد السيليكون

- مطلوب مطاحن دقيق بمصر

- عرض مطحنة الكرة الجيدة x cs

- what is grinding in india

- ملف مشروعات مصانع الاسمنت في مصر

- آلة تكسير الحجر marcent

- تأثير كسارة الحجر تأثير pdf

- process and function of electro refining of proton of copper

- الهواء في الإطارات الفك المحمول محطم مصر أسعار

- آلة طحن نوع الركبة العالمية x a x a

- أفضل مصنع كسارة الجرانيت في العالم

- Manufacturers In Nigeria

- صورة وحدة غربلة محطم

- تأجير كسارة صغيرة صغيرة في المملكة المتحدة

- صانع الرمل الحجر الجيري الصخور تأثير محطم

- glass grinder playing in what is good

- مطحنة حمام رطبة 2 لتر سهلة

- مخروطي حجم الكرة المطاحن

- تستخدم آلات الجبس للبيع

- separation of silica feldspar and kaolin

- آلة صنع الجرانيت الاصطناعي

- الكرة_مطحنة_المواصفات_الفنية

- هیدرولیک جایگزین سنگ شکن

- concerts at rock crusher in lecanto fl

- 250t لكل ساعة عملية إنتاج الحجر الجيري

- كسارة حجر مستعملة للبيع في فلوريدا

- المحمول كسارة خام الحديد الموردين كسارة السودان

- highbankers for sale in canada

- إكتشاف مناجم الذهب في سيناء بتاريخ

- در فیلیپین سنگ شکن بالاست

- در مورد صنعت سنگ شکن

- laboratory milling machines

- الآلات المستخدمة في استخراج الحجر الجيري

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت