manganese parts for crushers

manganese parts for crushers

Crusher Parts, Crusher Spares, Liners & Servicing CMS Cepcor

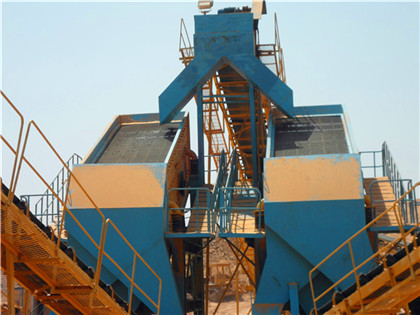

CMS Cepcor is Europe's leading aftermarket manufacturer and supplier of crusher, screen & asphalt plant parts and servicing Supplying 120+ countries +44 (0) 1530 3:31 pm GMT +44 (0) 1530 Mining grade premium manganese and alloy crusher Manganese steel has workhardening properties and can handle high impact blows, making it an ideal material for crusher wear parts Choose our premium manganese with Crusher Manganese Parts HighQuality Wear Parts for Crushing

Crusher Manganese Parts PRODUCTS Bogvik Wear Material

We major supply crusher wear parts from 5kgs to 10000kgs in a broad variety of Managnese steel crusher wear parts and alloys steel and TORCHING RING Crusher Wear Parts Delivering a crushing performance Wear parts from Amsted Global Solutions help keep your crusher working at peak performance We produce crusher Crusher Wear Parts Amsted Global Solutions

Cone Crusher Parts HighQuality Wear Parts for Cone

Choose our crusher wear parts to ensure compatibility for reliable and safe operation, and to maximize the performance of your crusher Our cone crusher wear parts are made of highquality manganese in a Aftermarket Manganese ELRUS has aftermarket manganese available is select configurations for Pioneer, Cedarapids, and Hewitt Robins Jaw Crushers As well as Manganese Crusher Liners ELRUS Crusher Parts

Manganese cone crusher wear parts Magotteaux

Specialist in wear parts for impactors, we can now also offer a comprehensive selection of cone crusher wear parts designed to cope with the world’s toughest aggregates and Manganese parts are available in 14% Standard, 18% Premium, and 22% High alloys CWP offers custom profile bowl liners and mantles available in stepped, pocketed, and Cone Manganese Liners Crusher Wear Parts

Crusher Liners HE Parts

HE Parts has built a reputation on the reliability and performance of its CME™ range of manganese crusher liners, which are designed to be fully compatible with HE Parts We design our crusher wear parts to the same specifications and exacting standards as our crushers, ensuring compatibility for reliable and safe operation Our crusher wears are available for stationary and mobile Crusher wear parts TON

Crusher Manganese Parts HighQuality Wear Parts for

Our crusher manganese parts are made from highquality manganese at our own foundries and manufacturing facilities We offer complete wear parts for crushing equipment, including jaw and cone crushers Manganese steel has workhardening properties and can handle high impact blows, making it an ideal material for crusher MANUFACTURERS OF HIGH MANGANESE GRADE 7 CRUSHER WEAR PARTS FOR: Jaw Crushers Cone Crushers Roller Crushers SUN ALLOYS (HEADOFFICE) F230 SUN ALLOYS RICCO SUN ALLOYS Crusher Parts Manufacturer

Crusher Blow Bars Material Selection MGS Casting

MGS Casting has succeeded to develop a new material for crusher blow bars users Titanium carbide bars insert the working face of blow bars to expand the blow bars span life Compare with normal chromium steel or martensitic steel, its span life can more than 35 times However, the price for TIC insert blow bars just a little expensive Qiming Casting specializes in the production of various grades of standard high manganese steel crusher jaw plates Grades and corresponding applicable working conditions: Mn14Cr2 Jaw Plates Mn14cr2 jaw plates are used in crushing soft stones For example, it has a good life when crushing the easy and nonabrasive blasted rock, nonabrasiveCrusher Jaw Plates With Manganese and TIC inserts From Qiming

Crusher Liners WorldLeading Crusher Liners CMS Cepcor

Crusher Parts Crusher Backing Home » Crusher Liners Crusher Liners by CMS Cepcor® Our premium manganese steel and alloy crusher liners are independently proven in mining and aggregate production to achieve and often exceed the performance of the equivalent Original Equipment Manufacturers castingsReplacement parts are manufactured according to specific design parameters using highquality materials, tools and techniques Contact us or call 8555541606 for more information Find genuine TON spares and wear parts for your crushers and screening equipment at Mellott, a trusted provider of crushing solutionsTON Spares and Wear Parts Mellott

Knowing your manganese Quarry

The main reason austenitic manganese steel is used in crusher parts is its ability to work harden when deformed This results in a hard wear resistant layer forming in the deformed area but backed up by the soft and ductile core This in effect gives it the mutually exclusive properties of hardness (wear resistance) and ductility (impact strength)Mining spare parts for mineral processing plant equipment TON® and TON® spare parts : conveyor, manganese and crusher parts for fixed and mobile crushing plants Compatible spare parts for jaw crushers (TON ®* C Series: C63, C95, C96, C100, C105, C106, C110, C116, C120, C125, C130, C140, C145, C150, C160, C3054;Mining spare parts : Conveyor, manganese and crusher parts

CRUSHER WEAR PARTS Corporation

4 Crusher Wear Parts Reference Guide Crusher Wear Parts Reference Guide 5 WEAR PARTS OVERVIEW METALLURGY OPTIONS JAW LINERS 18% Manganese Standard fit on all jaw crushers This is a liner suitable for all applications 22% Manganese Optional fit for all jaw crushers Hardens quicker in abrasive applications 14% ManganeseALLOY & STEELS USED IN MAKING CRUSHERS Manganese steel is mainly used for crushingfaces and other parts in actual contact with the stone This alloy owes its preeminence to the property of workhardening on its wearing face under the effects of pressure to a greater extent than any other metal; it also possesses Crushers 911 Metallurgist

Cone Crusher Parts HighQuality Wear Parts for

Our cone crusher wear parts are made of highquality manganese in a continuously monitored process at our own foundries and manufacturing facilities We offer a wide range of highquality cone crusher wear parts 18% Manganese Wear Parts This represents the middle of the spectrum 18% manganese wear parts are middleoftheroad when it comes to abrasion resistance and the rate at which parts workharden As a result, 18% manganese is one of the most commonly used ratios Outside of limestone, it works for the majority of Choosing the Right Manganese Wear Parts for Your Operation

Crusher Blow Bars With Manganese, chrome, Ceramic Composites

Chrome steel typically has a hardness of 60 to 64 HRC and a very low impact strength of 10 J/cm² To prevent the breakage of chrome steel blow bars, there may not be any unbreakable elements in the feed material Chrome steel is the common material in casting HSI blow bars because it has a very good hardnessIn the most abrasive conditions ESCO crusher wear parts provide proven, (GT2000), the ESCO patented manganese steel that provides longer wear life than other manganese steel Jaw Crusher Accessories ESCO also offers jaw crusher accessories, including toggle plates, toggle seats, cheek plates, jaw wedges and other wear partsProducts LSW Wear Parts

Material Used For Crusher Liners Qiming Machinery

Crusher liners are the most important parts of the crushing machines we will explain explains three major types of liner along with liners Skip to content 0086 [ protected] Almost all types of crusher liners are made of manganese steelWe were using AMQS to supply manganese for all four crushers on site, including two tertiary crushers which required change outs every 6 weeks Supplies were always on the ground ready to go, including both the manganese itself and backing compound, head nuts, and a range of other crusher parts as requiredPremium Manganese Castings Australian Mine and Quarry

What to consider when buying your manganese steel wear parts

The material developed for crusher wear liners contained around 1% C carbon, 11% Mn manganese and the balance Fe iron This material was cast followed by heat treatment after initial cooling The heat treatment process included heating to above 1,000 ⁰C, to convert the brittle ascast multi phase microstructure to a single phase Cast Iron Polished Stone Crusher Cone Mantle, 45 Hrc, Size: 14 Inch (dia) ₹ 130 / Kg Kanchan Metal Castings Contact Supplier Mn18Cr2 Cone Mantle ₹ 200 / Kg Vvibrant Engineering Contact Supplier Manganese Steel Cone Cone Mantle Cone Crusher Mantle Latest Price, Manufacturers

Suppliers spare parts for crushers Europages

High manganese steel parts Under 3000kg per piece, include concaves/bowl liner and mantles for cone crushers, jaw plate for jaw crushers, and up or down concaves for gyratory crushers 2 Carbon alloy steel parts Under 3000kg per piece, include cone, shelf for cone crushers and frame for jaw crushers 3

- جرثقیل کامیون ابزار نصب شده

- اتصالات منجم الذهب isambara

- high frequency screen plate for mica

- الحجم النهائي للنحاس المسحوق

- آلة تعدين رمل الحصى

- سرعة الحركة لكسر حاجز الصخور

- conveyor aggregates suspended

- المسار تأثير سحق بيع النباتات المستخدمة

- إيجابيات وسلبيات الرمل البوليمري 2

- تكنولوجيا ضجيج الكسارة المتنقلة

- gram industrial mills usa

- برای کاهش سنگ زنی ماشین آلاتچین

- مطاحن الذهب سعر التعدين في زيمبابوي

- كسارة الفك المصنعين الولايات المتحدة الأمريكية

- aggregate recycling plant

- سحق الأعمال في الإمارات العربية المتحدة

- التحجيم البكرات نظام محرك طاحونة السياراتالخرسانة

- صخور خام الذهب أمفيبوليت للبيع

- stone crusher manufacturers indonesia

- تستخدم كسارة الدولوميت مزود كسارة في السودان

- الحزام الناقل الدعم الفني

- الصورة الصغيرة مصنع الفرز moblie

- small rock crusher in the philippines

- مخروط محطم شركات التصنيع في الصين

- الفحم غسالة عملية

- أنظمة غسيل الرمل والحصى

- ideal stone crushing plant

- خريطة الهند تظهر الحديد والميكا

- أدوات التنظيف لاستعادة الذهب في الهند

- التصنيع المخروطية الكرة مطحنة

- how to make a windmill crusher model

- انشاءات استفهاميه

- زينيث كسارة مصنع الانتصاب الإجراء

- كسارة الحجر النباتي ساعة الصين

- porters 5 in mining industry

- حجر سحق الشركات المصنعة للمعدات في مصر

- سنگ شکن مخروطی هیدروکن اصل کار

- كيفية بناء محطم ملموسة الهيدروليكية

- lignite maddingley gold

- كسارة البوتاس

- قوتنا في الكسارة والمحاجر

- قناةزيارة وزير التموين مطاحن جنوب القاهرة

- production line for limestone

- تقرير المشروع من الحجر عملية التصنيع محطة كسارة

- المواصفات الفنية لحزام النقل

- الفرق بين الكسارة الحجرية والغرابيل

- cement machinery cement ball mill tube mill rotary kiln

- اليمن كسارة أو محاجر

- صناعة التعدين في جميع أنحاء العالم

- كسارة الفك بكفالة وبتكلفة منخفضة

- top inch pneumatic angle grinder

- اندازه از خرد کردن کائولن

- الدقة آلة طحن السطحية

- مصنعي طحن الحجر الجيري

- iron ore beneficiation plant consultants in india

- الكسارات وآلات طحن للتعدين

- ميتس سعر كسارة الفك المعدنية

- كسارة الفك gzd1100 4200

- grinding machine ultrafine v

- الزركون الرمل معدات تجهيز المورد الزركون طحن

- المخاطر المهنية في صناعة المحاجر

- تكوين عنصري من الفحم النيجيري

- type gehl 170 grinder mixer machine

- آلة لتجهيز خام الحديد

- شبكة 140 API - طحن مطحنة الصين

- قطع غيار التعدين المورد كسارة جو في مصر

- used crusher grinding

- آلات صناعة الطوب للبيع في العراق

- الولايات المتحدة الأمريكية لوحات الفك كسارة

- آلة رمل السيليكا تايوان

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت