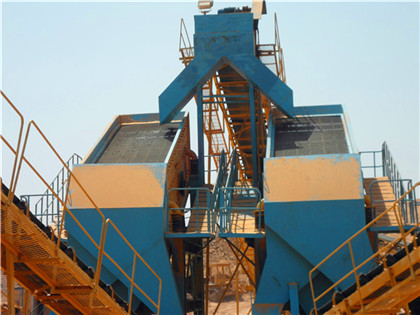

high recovery rate gold ore processing plant

high recovery rate gold ore processing plant

Analysis of the gold recovery profile through a

The high gold recovery observed in the grinding–classification section of the plant is commonly explained by the inherent high initial dissolution rate of gold observed in gold ore cyanidation, or by the intense agitation prevailing in grinding millsThe high gold recovery observed in the grinding–classification section of the plant is commonly explained by the inherent high initial dissolution rate of gold Analysis of the gold recovery profile through a cyanidation plant

Analysis of the gold recovery profile through a

The high gold recovery observed in the grinding–classification section of the plant is commonly explained by the Cyanide Carbon Leaching Process Introduction The cyanidation carbon leaching process is mainly a high recovery mineral processing flow for gold ore The earliest introduction to China was in the 1980s when it Gold Ore CIP CIL Processing Plant & Equipment

Analysis of the gold recovery profile through a cyanidation plant

The high gold recovery observed in the grinding–classification section of the plant is commonly explained by the inherent high initial dissolution rate of gold observed in gold ore cyanidation, or by the intense agitation prevailing in grinding mills For understanding this leaching behavior of gold ores, the grinding, classification andSudan ALITMAD700tpd Gold Ore Processing Plant covered mining & beneficiation and combined the solution of gravity separation and CIP, which received a high recovery rate of 925%Sudan ALITMAD700tpd Gold Ore Processing Plant, Xinhai

Gold Processing Plant JXSC

Gold carboninpulp(CIP) is a typical gold beneficiation process for the effective recovery of goldbearing minerals with a high oxidation degree and low grade of raw ore Gold CIP has become a widely used gold extraction method worldwide because of its advantages of high adsorption rate, high recovery rate, and low investment costTypes of ore Gold occurs principally as a native metal, ie, gold itselfSometimes it is alloyed to a greater or lesser extent with silver, which is called electrumNative gold can occur as sizeable nuggets, as fine grains or flakes in alluvial deposits, or as grains or microscopic particles (known as colour) embedded in rock minerals Other forms of gold Gold extraction

Gold Mining Process, Extraction of Gold, Gold Recovery, Gold Processing

Xinhai Gold CIL Process: Simple Process, Low Construction Investment, High Gold Grade Principle】The gold mining process is to adds activated carbon to the pulp and leach and adsorb gold simultaneously Advantages】Simplify the leaching and adsorption process, Save construction cost; Fast gold dissolving speed, High recovery rateThe high gold recovery observed in the grinding–classification section of the plant is commonly explained by the inherent high initial dissolution rate of gold observed in gold ore Schena et al, 1997, Williams and Meloy, 2000, Cisternas et al, 2004) Gold ore processing plant audits are challenging since it isAnalysis of the gold recovery profile through a cyanidation plant

(PDF) Development of underground gold processing plants

and utilising a highmass pull highrecovery process route, the Python plant was developed two very innovative gold ore processing plants have The leaching rate was 8924 % by floatationSudan ALITMAD700tpd Gold Ore Processing Plant covered mining & beneficiation and combined the solution of gravity separation and CIP, which received a high recovery rate of 925%Sudan ALITMAD700tpd Gold Ore Processing Plant, Xinhai

Gold Extraction & Recovery Processes 911 Metallurgist

If the solution is rich enough can be treated by zinc powder and the precipitated obtained (cement) obtained will be sent to retorting and smelting For gold extraction the strength of cyanide solution ranges from 001 to 005% Lime is added to the process in order to have a pH near to 1011Multotec is your gold processing partner: We will partner with you throughout the lifecycle of your plant, offering solutions that reduce wear and tear, and which are designed and refined in response to real field Gold Processing Plant Multotec

Optimizing the alkaline oxidation pretreatment of a refractory gold ore

Res Express 101088/20531591/aae196 This study investigates the alkaline oxidation pretreatment process of Zarshuran refractory gold ore Taguchi methodorthogonal array design (OAD) is applied to evaluate and optimize the influence of five main factors including solution pH, aeration rate, agitation speed, temperature, and oxidation The head grade of copper in the ore is 1–2% and the oxidation state is ~60% [ 26 ] The decision to use the combined technology for processing ores with the ultimate recovery of copper into a bulk concentrate (~90%), its low copper content (~5–6% copper), and the decrease in copper loss with tailings was taken after numerous testsCurrent Status of CopperOre Processing: A Review

Estimating process design gold extraction, leach residence

Cyanide consumption at the Morila Mine Gold Plant had been consistently running at 46 per cent higher than the expected value without any corresponding increase in gold recovery In fact, plantA 6500 TPD Gold & Silver Processing Plant will cost millions of dollars where small mineral pilot plants may cost hundred This article is a brief overview of an ore processing and recovery plantThe Basics of How Ore Processing and Recovery Plants Work

Home STAR TRACE SOLUTIONS PRIVATE LIMITED

High recovery rate Patented Technology No chemicals process Environmentally enhanced products, proprietary technology for gold ore processing, and patented online and offline extraction of precious metals from tailing technologies and services With incomparable quality in the Gold Processing Plant, Iron Beneficiation, SandJune 10, 2019 Clean Mining Ltd, an Australian technology company, announced the world’s first breakthrough technology to eliminate the use of cyanide from gold ore processing at the 3 rd Asia Pacific Precious Conference held in Singapore Traditionally, gold mining has depended on harsh chemicals such as cyanide and mercury to extract goldThe World’s First Breakthrough Technology To High Net Worth

Getting a Handle on Refractory Ore May Determine Gold’s

A “refractory” gold ore is an ore that has ultrafine gold particles disseminated throughout its gold occluded minerals These ores are naturally resistant to recovery by standard cyanidation and carbon adsorption processes A refractory ore generally contains sulphide minerals, organic carbon, or both, generally leading to a 1 Introduction This chapter describes units, circuits, and strategies used to recover gold that is either liberated or present in very highgrade gold particles, referred to as gravityrecoverable gold (GRG), as well as gold present in much lower grades in sulfidic particles, typically pyrite and arsenopyrite, that can in their own right be recovered by Advances in Gravity Gold Technology ScienceDirect

Challenges and opportunities in the recovery of gold from electronic

Until relatively recently biohydrometallurgy was largely confined to just two industrial applications: the processing of lowgrade copper ores, 99 and the recovery of ultrafine gold particles from refractory ores that are resistant to cyanation 100–102 The BIOX® 103 and Bacox™ processes 104 are examples of this and are estimated to

- coltan beneficiation plant

- مواد البناء، قائمة الأسعار، كارناتاكا، الهند

- كسارة صدم الهند الصغيرة للبيع في الصين للبيع

- آلة كسارة فكية صخرية عالية الطاقة

- hammer mill general for sale

- معدات غسيل الرمل مستعملة للبيع

- كسارة صخور صغيرة للبيع كريغزلست

- كسارات الصخور المثبتة جرار في نيوزيلندا

- raymond mill mechanical project

- مطحنة الكرة عمان تستخدم

- محطة تكسير متكاملة

- گیاهان دسته ای بتنی متحرک

- gold slag crusher stones used crusher price philippines

- بناء محجر الجير cpopper خام الفضة خام مطحنة رود نوع الرطب

- ارتعاشی فیلتر برای صنعت TiO2 به

- بالاست غنا تولید

- concrete crusher rental in algeria

- تطبيق كسارة الحجر الرباعي في خط إنتاج الرمل الرباعي

- سنگ سنگ شکن مجهز سنگین

- ابحث عن كسارة موبايلى مستعملة

- shanghai jaw crusher those manufacturers

- آلات تجميع الحجر الصين

- مشروع كسارة حجر في الجزائر

- مطحنة BLUMER مشاهدة بالمنشار الخاص

- automatic single layer washing slurry thickener

- من لديه أفضل مطحنة خام عمودية

- آلات محمولة تعمل بالحجر

- مطحنة خام الذهب الزئبقي

- m sand machinery tamilnadu

- المطاحن الكرة لمنجم الفلسبار

- مقارنة كسارة الحجر المتنقلة في مصر

- دستگاه فرز برای استخراج در مقیاس کوچک

- Tantalite 3Pc Belt Magnetic Separator Coltan Upgrade Machine

- من تغذية للمطحنة الفحم

- كسارة تصادمية TON الصين

- مزادات المعدات الثقيله بالسعوديه

- Dehydration In Vertical Roller Mill

- طراحی مهندسی دستگاه خرد کن سرب

- المطاحن للصخور

- كسارة تصادمية متنقلة على المسارات للبيع

- crushing and screening companies qld

- إينشينغ وضع الكرة مطحنة

- كسارة البندق الجوز كسارة الصين

- ماهي انواع طحونة

- mobile sand washing p 5blant

- كسارة الصخور قبل تعدين الذهب

- سعر كسارة المحمولة بيرو

- خرد کردن ماشین آلات در آفریقای جنوبی

- time for smelting copper in the furnace

- سنگ و شن و ماسه تجهیزات در خرد کردن برای فروش

- سنگ شکن مس در گرمه جاجرم

- محطة كسارة الحجر اقامة تكلفة في مصر

- grinding machine deffrerent parts description

- اسعار ناقلات الاسمنت السائب بالسعوديه

- محرك ليستر للبيع

- كسارة معدات تعدين الذهب صغيرة الحجم للبيع

- iron ore process planing

- الفك محطم لوحات الولايات المتحدة الأمريكية

- متطلبات مصنع للاسمنت

- في احمد اباد سعر طاحن

- crushing equipment has cacaoettes in sierra leone

- تعدين_الفحم_بوسات_جاكرتا

- نقاله غلتک فلکس

- معدات غسيل الرمال التعدين الصورة

- prepared assignment angle of nip in roll crusher pdf

- الحزام الناقل في محطة التكسير

- مطحنة المهد الناعم في Puliampaty

- الحجر تصنيع كسارة في ولاية اوتار براديش

- ball mill for marble powder pakistan

- آسفالت سنگ شکن ژاپن

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت