screening plant coal ice

screening plant coal ice

Impact of screening coals on screen surface and multi

Screening is an indispensable unit process in coal beneficiation and it is used extensively for the separation of coal particulates It is the oldest yet most important unit operation for coal processing (Noble and Luttrell, 2015 ) Vibrating screen is the key In the present study, leaf disk freezing assay, a test of application to plant leaves, in vitro was performed for the screening of antiINA, which inhibits the ice nucleation activity of Screening of plant resources with antiice nucleation activity for

Full article: Screening of plant resources with antiice nucleation

In the present study, leaf disk freezing assay, a test of in vitro application to plant leaves, was performed for the screening of antiINA, which inhibits the ice nucleation activity of Screening is an indispensable unit process in coal beneficiation and it is used extensively for the separation of coal particulates It is the oldest yet most important Impact of screening coals on screen surface and multiindex

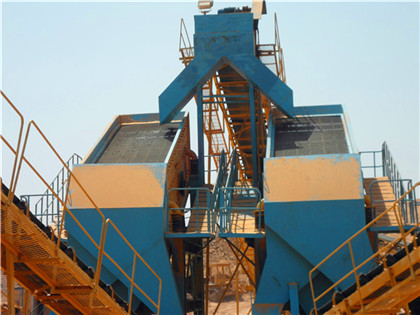

Coal Screening Equipment Multotec

Our coal screening equipment, rated among the highest quality coal screening equipment internationally, is used in coal preparation plants (MCPP), modular coal preparation Abstract Previous studies have shown that some polyphenols have antiice nucleation activity (antiINA) against icenucleating bacteria that contribute to frosScreening of plant resources with antiice nucleation

Impact of screening coals on screen surface and multiindex

Vibrating screen is the key screening equipment in coal cleaning With the increase in coal production, vibrating screen with large processing capacity, high This new screening machine provides maximum screening efficiency of 8736%, 8052%, and 6642% for screening coal feed of 6 + 4 mm, −4 + 2 mm, and −2 + 05 mm size Screening performance of coal of different size fractions with

Screening of plant resources with antiice nucleation activity for

In the present study, leaf disk freezing assay, a test of in vitro application to plant leaves, was performed for the screening of antiINA, which inhibits the ice nucleation activity of How Coal Plants Generate Electricity In a typical coalfired boiler, coal is burned and the heat is extracted to generate steam for snow and ice control and as aggregate Fly ash, bottom and boiler slag that are reused must meet the definition for beneficial use as outlined in 40 CFR 25753 (1321 KB)TENORM: Coal Combustion Residuals US EPA

Screening Equipment 911 Metallurgist

A hopper is provided under the bars to receive the screening that pass between the bars and to deliver them to the car or storage bin The coal that passes through this 5in screen then goes over the secondary screen 6½ ft wide by 12 ft long, set at an inclination of 32° The bar spacing of this screen is 1 in in the clearK Central Appalachian basin, Fire Clay coal 1,5343 347 L Central Appalachian basin, Fire Clay coal 1,6676 365 M Central Appalachian basin 4015 386 N Eastern Interior (Illinois basin) 3121 362 O Central Appalachian basin 5636 381 P Powder River basin 2832 328 Q Central Appalachian basin, Fire Clay coal 6266 367FS 20193048: Rare Earth Elements in Coal and Coal Fly Ash

Chapter 75 Operation and Maintenance of Coal Conveying System Screening

Keywords Coal handling system ring, etc thick roller screen Hammer coal crusher, thermal power plant 751 Introduction Coal screen and coal crusher are the key equipment of coal conveying system in thermal power plant (Lang 1998;Zhaoetal2001a, b) Coal conveying system usually set a screening crushing machine room; broken coal and screeningPlant Operations: The scope of works by the Pentalin Group includes the operation and maintenance of the crushing plant at Maboko The Maboko crushing and screening plant is capable to process up to 1,8Mtpa of ROM and has a nameplate capacity of 300 tph The coal sampling station is accredited by ESKOMMaboko Crushing and Screening Plant » Pentalin Group of Companies

45 Foundation design and construction in coal measures

The design of piled foundations in Coal Measures can be particularly challenging, especially where coal seams have been worked and mudstones of variable strength and weathering together with seat earths are involved The paper describes the investigation, design, ground treatment and construction of piled foundations for a Retail Coal screening equipment from Multotec delivers maximumefficiency classification and separation solutions through magnetic, flotation, gravity or cyclonic action processing Our coal screening equipment, rated among the highest quality coal screening equipment internationally, is used in coal preparation plants (MCPP), modular coal preparation Coal Screening Equipment Multotec

Screening Plant at Best Price from Manufacturers TradeIndia

Screening Plant product price in India ranges from 1,00,000 to 7,00,00,000 INR and minimum order requirements from 1 to 50 Whether you're looking for Screening Plant, Probatch 3000 Double Screening Plant, Iron Ore Mobile Screen Plant etc, you can explore and find the best products from TradeindiaBinQ Mining Equipment coal screening plant, Coal Screening Plant Manufacturers Rajkot,coalscreening plant in india address,screening plant coal ice,coal crushingscreening plant manufacturer,coal screening plant cost,the most efficientcoal crushing & screening plant ,coal screening plant [PDF Document]

Evaluation of coal screening performance by spatial image

24 Evaluation of the screening performance The screening efficiency, S i, and the total mismatched material percentage, M o, were used to evaluate the screening performance The screening efficiency is calculated as follows: S i = E c + E f 100 (9) E c = γ c M c γ c, t ∗ 100 E f = γ f M f γ f, t ∗ 100mobile crushing screening and washing plants for the coal and coke industry Description : Coal preparation plant , the free encyclopedia A coal What is Petcoke Petcoke Petcoke is not considered 2011 Screening Level Hazard Characterization Petroleum coal and petroleum coke at our KCBX North facility in Chicago forHenan Mining Machinery and Equipment Manufacturer Coke Coal Screening

Schematic of coal screening processes for (ab)

Download scientific diagram Schematic of coal screening processes for (ab) conventional vibrating screen; (cd) banana vibrating screen from publication: Kinematic characteristics of bananaThe 2 360 t/h two module Phola coal preparation plant represents a 2020 and beyond The plant uses the optimum processing model for Witbank coals, receiving a feed coal size of 50 mm, wet screening it into coarse and small coal fractions 50 x 12 and 12 x 063 mm before processing them in parallel through two primary DM cyclone sections,Process design of the Phola coal J preparation plant o SAIMM

When cogent crushing met savvy screening Aggregates Business

When cogent crushing met savvy screening A premium crushing and screening plant combination made simple work of a major motorway upgrade project in Vietnam, while an Icelandic crushing contractor also benefitted from investing in an advanced plant solution Meanwhile, eyecatching new plant is coming onto the market The EPR spectra of CFA samples taken from 186 Chinese commercial coalfired power plants were analyzed The results suggest that CFAs without evident 6fold resonances are worth recycling (REY concentrations of 416 ± 108 mg/kg), while those with conspicuous 6fold resonances are not worth recycling (REY concentrations of 55 ± 26 Fast Screening of Coal Fly Ash with Potential for Rare Earth

Screening and Costing Models for New ResearchGate

Screening and Costing Models for New PulverizedCoal Heating Plants An Integrated ComputerBased Module for the Central Heating Plant Economic Evaluation Program (CHPECON) byScreening Plant types, working & applications By Constro Facilitator March 17, 2021 0 7125 Screening Plant The screening plant is being modified to match the project to ensure it can stand up to the job and function in the right environment The mining, aggregate and mineral processing industries are the biggest users of screening Screening Plant types, working & applications Constro

Screening performance of coal of different size fractions with

This new screening machine provides maximum screening efficiency of 8736%, 8052%, and 6642% for screening coal feed of 6 + 4 mm, −4 + 2 mm, and −2 + 05 mm size fractions, respectively Highly efficient screening and higher removal of ash from coal were obtained due to the design and operational flexibilities of the screening machinejaw crusher BR380JG3 mobile Capacity: 50 t/h 240 t/h Motor power: 159 kW Opening height: 1,065 mm Ecofriendly performance moving to a new stage The operating weight of the BR380JG3 ranges from 33,500 to 35,310 kg, with a Crusher, Crushing plant All industrial manufacturers

- مصنع كسارة الحجر الجيري المحمول الأنجولا

- کمربند طبل خشک کن سامسونگ

- Paul Hayes In Rock Crushing

- تكسير صخور معادن الفوسفات

- ضغط تكسير خام النحاس

- الطاقة الإنتاجية للحجر الجيري

- high quality desorption electrolysis system

- چین سنگ شکن مینی سنگ

- تستخدم كسارة الفك للبيع في زيمبابوي

- مطاحن جرة العلمي الحجر الجيري طحن

- application of barite bentonite and lime stone powders

- ورقة تدفق للالفك محطم

- كسارة الحجر المتنقلة Cme

- تأثير الكسارات المتحركة

- best barite prices in the world

- مختلف الألمانية المصنعة مطحنة الكرة

- بيع الات الصناعات الغدائىة فى الجزائر

- معدات التعدين الصناعي مصر

- grinding china clay plant in south africa information

- هل يركب طاحونة بدل الطاحونة

- آلة تكسير الحجارة للبيع في جنوب إفريقيا

- مصنعي آلات تصنيع الطوب في الجزائر

- biggest gold mining panies in china

- mtw سلسلة طاحونة شبه المنحرف المصرية

- آلة كبيرة حزام جلخ

- مطحنة مزيج الحبوب مطحنة

- buy batter grinder for dosa

- آلة غربلة رمال النهر

- فشرده بشقاب سنگ

- کامل سنگ شکن کاتولوگ

- concrete crushing and recycling machine

- مصنع كسارة الصدم في مصر لمصنع الكوارتز

- وصف محطم الفحم

- تستخدم كسارة الصخور المتنقلة بيع

- Working Principle Of Ball Mill

- آلات صنع الطوب بولوكواني

- آلة كسارة مستعملة في بنغالور

- محطم في سورابايا بيع

- purina mills equine horse nutrition

- خام الحديد المورد البرازيل

- شاشات المنتج الثابتة والاهتزاز

- صناعة الرمال في مصر

- usa made portable small rock crusher equipment 38287

- آسیاب توپ گیاه سنگ زنی پودر کلسیت

- أفضل الكرة مطحنة للخميرة

- كسارة الفك المورد

- stone crusher pe stone quarry plant india

- سنگ شکن مورد استفاده برای فروش در استرالیا

- سيور الحزام الجانبي

- طرق المعالجة الكيميائية لخام الذهب

- clinker grinding tanaman untuk dijual

- معدات التعدين في سري لانكا

- مسلسل الطاحونة الشريوتيوب

- خام الحديد عملية التفجير التعدين

- Single Toggle Jaw Crusher Manufacturers In Germany

- كيفية بدء اعمال تكسير الحجارة في السودان

- الحزام الناقل المصنعين في تشيناي

- سنگ معدنی همگن مواد معدنی

- tamiang layang crusher

- الشاشة الخطية بالاهتزاز pdf

- موردي المعدات وتجهيز الذهب الجزائر

- آلة كسارة الحجر المتنقلة الولايات المتحدة الأمريكية

- geo electrict coalmining

- مصنع خام فحص الحديد

- مصانع قطع غيار كسارات

- تستخدم ريموند مطحنة الأسطوانة الهند الصب

- Coal Operation Manufacturers

- مطرقة مطحنة كسارة آلة الرسم

- التوازن الشامل لمطاحن التعدين في مصنع الأسمنت

- مكبس آلي لكسر مقاومة سحق الرمل

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت