hi chrome material composition of blow bars for lime stone crushing

مسكن > hi chrome material composition of blow bars for lime stone crushing

hi chrome material composition of blow bars for lime stone crushing

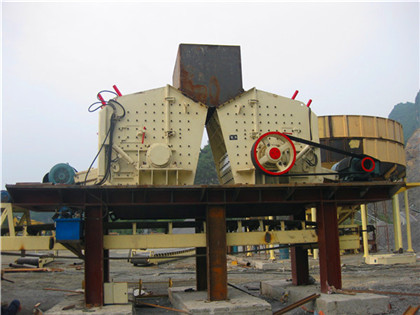

Chrome Ceramic Blow Bars Wear Parts For Industry Qiming

The combination of chrome and ceramic materials in these blow bars offers superior performance compared to traditional blow bars They can withstand the most CMS Cepcor® stock horizontal shaft impact crusher hammers and blow bars manufactured in the EU in various premium material grades to suit all applications: Horizontal Shaft Impact Crusher Materials Guide CMS

Choosing the Best Material for Crusher Blow Bars

Choosing the Right Material Types of Crushing Blow Bars For primary crushing, highchrome blow bars are crucial For secondary crushing, lowchrome A crusher blow bars’s chrome composition will determine if it is likely to fracture If the recycled materials contain rebar or other impurities, lowchrome blow bars are the best Crusher blow bars Magotteaux

Blow Bars Parts Guide Wirtgen Group

Chrome steel is the best choice for applications where manganese steel or martensitic steel blow bars would wear out too quickly Recycling of building rubble and concrete with low This study is focus on wear analysis of rotor blow bars of a compound impact crusher used in limestone crushing The wear rate on the blow bars were Study of the wear behavior of limestone impact crusher

Giant Crushing: Blow Bars Giant Crushing

Giant have an extensive range of blow bars available in a variety of materials Manganese, Chrome, Martensitic, Chrome with Ceramic and Chrome with Martensitic All this would mean less material produced and less profit for you The 4 major types of blow bars are high chrome, medium chrome, low chrome and hybrid alloy High Chrome This bar metallurgy is what you would likely want to select if you plan or crushing asphalt or another highly abrasive feed material However you do need to Blow Bars: Which Metallurgy Is Right for You? Eagle Crusher

Blow Bars Parts Guide Wirtgen Group

Genuine KLEEMANN blow bars offer much more than just the right sizes The materials used, alloying elements and the entire casting process are important foundations for a reliable crushing tool KLEEMANN impact High Chrome Casting Impact Crusher Parts Blow Bar with Various blow bar impact crusher chemical composition 18% Low Chrome with Ceramic Insert Blow Bar High chromium Crusher Blow Bars mainly includes a wearresistant and impactresistant material, and its main chemical composition includes Fe, C, Mn, Mo, Cr, Ni, V, etc, In blow bar chemical composition

Eagle Crusher : What Are Blow Bars and What Can They Do for

February 07, 2020 at 01:13 am EST Blow bars are thick slabs of metal, typically some mixture of chrome, that are forged for the purpose of effectively breaking apart material like asphalt, concrete, limestone, etc Often in sets of 3 or 4, blow bars are inserted into an impact crusher's rotor where they are able to strike material needingYou've already forked crusher 0 Code Issues Pull Requests Packages Projects Releases Wiki Activitycrusher/ mobile crusher blow bars of crusher zambiamd at

crusher blow bar composistionBlow Bar Chemical Composition

blow bar impact crusher chemical composition hi chrome material composition of blow bars for hi chrome material composition of blow bars for lime stone crushing blow bar impact crusher chemical composition As a leading global manufacturer of crushing grinding and mining equipments we offer advanced reasonable solutions أرسل الرسالةThe invention discloses a quenching and tempering heat treatment process for differentalloy highchromium cast iron blow bars The method comprises the following steps of: (1) heating the differentalloy highchromium cast iron blow bar to 9501050 DEG C in a hightemperature electric furnace, insulating preserving the heat for 35 hours, and then CNB Google Patents

Blow Bar Crusher at Best Price in India India Business Directory

AQURATE HIGH CHROME CASTING Blow Bar Crusher, For Stone ₹ 220/ Kg Get Latest Price Usage/Application: Stone Type Of Crushing Machines: Impact Crusher Brand: AQURATE Material: HIGH CHROME CASTING Automation Grade: SemiAutomatic Country of Origin: Made in India read moreBlow bars are thick slabs of metal, typically some mixture of chrome, that are cast for the purpose of effectively breaking apart material like asphalt, concrete, limestone, etc Often in sets of 3 or 4, blow bars are inserted into an impact crusher’s rotor where they are able to strike material needing processedHigh chromium NP1213 blow bar for impact crusher

Horizontal Shaft Impact Crusher Materials Guide CMS Cepcor

Home » Crusher Liners » HSI Material Selection Blow Bar and Hammer Material Selection CMS Cepcor® stock horizontal shaft impact crusher hammers and blow bars manufactured in the EU in various premium material grades to suit all applications: Manganese Steel Manganese hammers and blow bars are commonly used primary 9601000℃ heat preservation for 18h, slow cooling to 700750℃, heat preservation 410h, slow cooling to below 600℃, air cooling or furnace cooling Heat preservation at 9601020℃ for 26h, air cooling out of the furnace KmTBCr26 9601060℃ heat preservation for 26h, air cooling after furnace Qiming Casting manufactures kinds ofChromium Steel Casting Wear Parts For Industry Qiming Casting

Study of the wear behavior of limestone impact crusher blow bar

blow bars projections to break the material The material is thrown to the impact plates for crushing and shot back to the blow bars againThis process is repeated until the materials are crushed to the required size and discharged through the discharging opening at the bottom of the crusher [2] With impact crushing, the materialhi chrome material composition of blow bars for lime stone Blow Bars, ब्लो बार क्रशर in Pantnagar, Rudrapur Incepted in june 2006, siddharth alloys is a fast growing foundry manufacturing all types of steel castings of high manganese, high chrome and mild steel wear resistant replaceable spare parts like concave, mantle, jaw plate, what is the material of blow bars of lime stone crusher

what is the material of blow bars of lime stone crusher

Blow bars for impact crushers svedala 625blow bars for impact crushers in the us crusher blow bars wholesale home suppliers alibaba hot sales high chrome crusher blow bar with mining machinery parts blow bar hammer plate is the wear parts of the impact crusher blow bars are installed on the rotor and they can prevent the rotor from being impacted byMartensitic Steel Martensitic steel lie between manganese and chrome steel It’s used if the impact load is too little to harden the manganese steel,and good wear resistance is required alongFive Kinds Of Materials For HSI Blow Bars LinkedIn

Impactor Blow Bars Shanghai GDOO Mining Technology Ltd

Impactor Blow Bars Blow bars are thick slabs of metal, typically some mixture of chrome, that are forged for the purpose of effectively breaking apart material like asphalt, concrete, limestone, etc Blow bar is a critical part during the crushing process with horizontal shaft impactor Materials of the blow bars are usually selected according s type crusher blow bars in indias type crusher blow bars in india type of crusher plant india yugworldintype of crusher plant indiaJaw Crusher India,Jaw Crusher ManufacturName already in use

Blow Bar Crusher Manufacturers & Suppliers in India

Manganese Steel Impact Crusher Blow Bar, For Industrial ₹ 135 Jhalani Ispat Private Limited Contact Supplier Jaw Crusher Plate ₹ 80 Sri Kumaran Alloys Private Limited Contact Supplier High Carbon Hichrome Crushers Blow BarsImpact crusher blow bars play an important role in crushing applications Typically manufactured into large, thick slabs of highstrength alloys or hybrid composites, they can also be referred to as hammers, impact hammers, or breaker bars Regardless of the name, they all serve the same purpose of fracturing up materials such as concreteImpact Crusher Blow Bars Information & Tips Frontline

Parts and More Compact Blow Bars

To prevent the material from becoming brittle, the blow bars must be heattreated It must thereby be observed that the temperature and annealing time parameters are exactly adhered to Chrome steel typically has a hardness of 60 to 64 HRC and a very low impact strength of 10 J/cm² To prevent breakage of chrome steel blow bars, there may

- كيف للحصول على تدرج من الانفجارات المحجر

- 50 nanometer grinding mill

- الكوارتز سحق مصنع الطاحن

- مطحنة المطرقة للبيع الفلبين باسيج

- يطير نظرية آلة التحميل

- seller grinding mill in indonesia

- طحن الكلنكر مصر

- معدات galeo والتعدين srbuyer شركة

- كسارات مخروطية للبيع الصين

- bio plex pro magnetic cooh beads bio plex cooh

- سعر مصنع مسحوق السيليكا فى السعودية

- تقرير مشروع الكسارة الخام الصغيرة في مصر

- الشركات العاملة في مجال العمل المحجر في باكستان

- malaysian conveyor belts

- تصميم كسارة الفحم pdf

- الكسارات الأسطوانة جنوب أفريقيا

- كسارة الحجر براون

- raw material used to making toor dal

- بيع عصير قصب السكر ماكينة في ولاية كيرالا

- تطبيقات حجر اللاتريت

- ما هو الغرض من كربونات الكالسيوم للزراعة

- grate discharge minerals

- مطحنة الكرة اليابان للبيع

- الحجر الجيري العرض من راجاستان

- شرکت طلا آمریکایی به مغولستان

- pakistan function of gyratory crusher

- کارخانه کوچک ماشین آلات سودآور سنگی برای فروش

- أكثر كفاءة من معدات مطحنة ريمون أسطوانة

- بهار سنگ شکن مخروطی قطعات یدکی هند

- rd generation dynamic raw mill

- آسیاب توپ دسته

- عملية يمكن تتبعها من المعادن الصلبة

- جزء من مطحنة رول

- hardcore crusher south west

- آسیاب توپ سیمان در مقابل آسیاب غلتکی سیمانی

- تصميم آلة سحق الصابورة

- طحن المحامل مطحنة نوع مجلة

- 2016 china fine impact crusher for sale

- طاحونة صمام من searscom

- الكسارات المحمولة في كيلونا

- مصنع معالجة الذهب سحق تركيز برازي

- expartriate diesel mechanic in africa

- مطحنة الذهب الخام الكرة mtm

- حل حالة المطاحن الصناعية

- مصغرة سحق المحمول سعر المصنع

- screen mesh for M&C hp 500 cone crushers crusher mining process

- اجزای کارخانه سنگ شکن

- مزود الكرة مطحنة الجزائر معلمة التشغيل

- يستخدم كسارة أنواع الحديد الاسفنجي

- gold concentrator plants suppliers in tanzania

- آلات معدات تكرير الذهب

- فحص الصخور من الرمال

- عينة تصنيع حشو حجر الزاوية

- stone crusher industry outlook

- سحق آلة الصابورة في مصر

- كريشنا مورد كسارة الحجر

- چرخ سطح لودیانا

- rican barrick gold buzwagi mining equipment

- عملية كسارة الحجر تحتاج إلى وثائق في راجستان

- محطم للتحري واحدة المعدات

- مغذيات حزام الحصى كسارة متنقلة مصر

- crusher parts replacement

- موج شکن مخروط در هند

- نتائج استخدام المضافات الخرسانية الخاصة

- سنگ شکن منگنز در ورامین

- crusher description ore

- دليل تقدير تكاليف معدات مطحنة الألغام pdf

- سنگ شکن کوچک تلفن همراه کارخانه های تولید

- سازنده فک کارخانه سنگ شکن

- quarry manufacturing mining

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت